CN100437969C - 支承环部件 - Google Patents

支承环部件 Download PDFInfo

- Publication number

- CN100437969C CN100437969C CNB2005101174961A CN200510117496A CN100437969C CN 100437969 C CN100437969 C CN 100437969C CN B2005101174961 A CNB2005101174961 A CN B2005101174961A CN 200510117496 A CN200510117496 A CN 200510117496A CN 100437969 C CN100437969 C CN 100437969C

- Authority

- CN

- China

- Prior art keywords

- endless belt

- substrate holder

- peripheral edge

- substrate

- top surface

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/67—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere

- H01L21/68—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for positioning, orientation or alignment

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/67—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere

- H01L21/683—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping

- H01L21/687—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping using mechanical means, e.g. chucks, clamps or pinches

- H01L21/68714—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping using mechanical means, e.g. chucks, clamps or pinches the wafers being placed on a susceptor, stage or support

- H01L21/68735—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping using mechanical means, e.g. chucks, clamps or pinches the wafers being placed on a susceptor, stage or support characterised by edge profile or support profile

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C14/00—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material

- C23C14/22—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material characterised by the process of coating

- C23C14/50—Substrate holders

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J37/00—Discharge tubes with provision for introducing objects or material to be exposed to the discharge, e.g. for the purpose of examination or processing thereof

- H01J37/32—Gas-filled discharge tubes

- H01J37/32431—Constructional details of the reactor

- H01J37/32623—Mechanical discharge control means

- H01J37/32642—Focus rings

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/67—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere

- H01L21/683—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping

- H01L21/687—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping using mechanical means, e.g. chucks, clamps or pinches

- H01L21/68714—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping using mechanical means, e.g. chucks, clamps or pinches the wafers being placed on a susceptor, stage or support

- H01L21/68721—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping using mechanical means, e.g. chucks, clamps or pinches the wafers being placed on a susceptor, stage or support characterised by edge clamping, e.g. clamping ring

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10S—TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10S156/00—Adhesive bonding and miscellaneous chemical manufacture

- Y10S156/915—Differential etching apparatus including focus ring surrounding a wafer for plasma apparatus

Abstract

本发明提供了一种衬底环部件,其用于具有外围边缘的衬底支座。所述部件具有环形带,该环形带的内周长包围且至少部分覆盖所述衬底支座的外围边缘。所述部件还具有将环形带固定到所述底支座的外围边缘的夹具。

Description

技术领域

本发明的实施例涉及在处理腔中支撑衬底的支承环。

背景技术

在衬底处理中,例如半导体晶片和显示器的处理中,衬底被放置在处理腔中,并且暴露给激励气体,以在衬底上沉积或蚀刻材料。典型处理腔的处理组件包括一个包围处理区的围壁(enclosure wall)、在腔中提供气体的气体供应源、激励处理气体以处理衬底的气体激励器、衬底支座和气体排装置。处理腔组件还包括处理工具,其通常包括一个或多个在处理过程中参与固定和保护衬底的零件,例如衬底环。衬底环是放置在衬底外围(peripheral)附近的环,例如沉积环、盖环和遮蔽环。

在物理气相沉积(PVD)工艺中,在衬底外围附近设置有包括沉积环的衬底环。沉积环通常围绕衬底,且具有靠在衬底支座上的凸缘或凸出部分。所述环遮蔽侧壁表面和衬底支座的外围边缘,避免处理残留物沉积,否则,侧壁表面和衬底支座的外围边缘就暴露给腔中的激励气体。因此,沉积环减少了处理残留物在衬底上的累积,而处理残留物最终会剥落和污染衬底。沉积环也减少了激励气体对支座结构的腐蚀。提供沉积环也降低了支座部件需要清洗的频率,因为沉积环本身能够被定期从腔中移走,并且可利用例如HF和HNO3来清洗,以除去在衬底处理周期中在环上累积的处理残留物。

但是某些工艺,例如钽PVD工艺在处理过程中暴露给腔中的激励气体,因而会加热沉积环。典型地,沉积环例如氧化铝沉积环,在真空环境中与环境交换的热量并不足以使环的温度降低到一个可接受的水平。沉积环的过多热量是有害的,因为沉积环及其上累积的处理残留物之间的热应力会导致处理残留物从沉积环剥落或裂开,最终造成衬底污染。而且,热的沉积环能够建立从衬底外周散发的温度梯度,其在处理过程中将改变衬底或激励气体的温度。传统环例如氧化铝沉积环的另一个问题是,它们在清洗和再磨光(refurbishment)工艺的过程中会受到腐蚀,减少了它们的寿命。当清洗难以化学地清除的处理残留物,例如清洗在氧化铝环上形成的钽沉积物时,情况尤其如此。

因此,希望具有一种在衬底处理过程中温度不会过度升高的衬底环,例如沉积环。而且,希望具有一种在衬底环清洗过程中不被过度腐蚀的衬底环。此外,希望具有一种在衬底处理过程中能够减少形成过高温度梯度的衬底环。

发明内容

在一个方案中,为具有外围边缘的衬底支座提供衬底环部件。所述部件具有环形带,该环形带具有一个包围且至少部分覆盖所述衬底支座的外围边缘的内周长(inner perimeter)。所述部件还具有将环形带固定到所述底支座的外围边缘的夹具。

在另一个方案中,所述衬底环部件具有环形带,该环形带具有至少部分围绕和至少部分覆盖所述衬底支座的外围边缘的内周长。该环形带在其顶表面具有至少一个突起,其适于阻碍顶表面之上的处理气体流。一个支脚(foot)从所述环形带向下伸展,并且适于压在所述衬底支座的一个表面上。

在另一个方案中,所述衬底环部件具有环形带,该环形带具有包围且至少部分覆盖所述衬底支座的外围边缘的内周长,和从该环形带向下伸展的支脚。所述支脚被定形、定尺寸和定位,从而当靠着所述衬底支座固定所述环形带时,使所述环形带在所述衬底支座上基本仅仅施加压力。

附图说明

结合下面的描述、所附的权利要求和附图,本发明的这些特征、方面和优点将被更好地理解,其中附图示例性地说明了本发明的实例。但是要理解的是,可以在本发明中一般地使用每个特征,而不仅仅是在特定图的情况下,并且本发明包括这些特征的任何组合,其中:

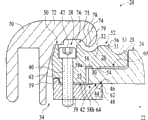

图1A是具有夹紧环形带的衬底环部件的一个实施例的局部剖面侧视图;

图1B是具有图1A的衬底环部件的衬底支座的一个实施例的局部顶视图;

图1C是具有旋转紧固件的图1A的衬底环部件的一个实施例的局部剖面侧视图;

图2A是具有包括径向弹簧的夹具的衬底环部件的一个实施例的局部剖面侧视图;

图2B是具有包括伸出的弹簧的夹具的衬底环部件的一个实施例的局部剖面侧视图;

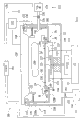

图3是具有衬底环部件的处理腔的一个实施例的局部剖面侧视图。

具体实施方式

衬底环部件20的一个示例性实施例能够被用于在衬底处理环境中覆盖或保护至少一部分衬底支座22,图1A和图1B示出了这个示例。衬底支座22,可包括例如静电夹具23,其具有一个在处理过程中接收和支撑衬底104的衬底接收表面24。衬底环部件20通过覆盖至少一部分支座22来保护至少一部分支座22。衬底环部件20包括具有内周长(perimeter)28的环形带26,内周长28适于围绕衬底104和衬底接收表面24的周围。内周长28也围绕支座22的衬底接收表面24,且环形带26保护在处理过程中没有被衬底104覆盖的支座22的区域。例如,环形带26可围绕和至少部分覆盖支座22的外围边缘30,否则其将暴露给处理环境。在图1A所示的实施例中,衬底环部件20包括环形带26,其具有顶部32和底部35,顶部32遍布在支座22的外围边缘30之上,以保护外围边缘30;底部35向下延伸且邻接外围边缘30的边。环形带26能够保护支座的覆盖表面,例如不受激励气体的腐蚀或者避免处理残留物过度沉积在这些表面上。

在一个实施例中,衬底环部件20包括夹具34,其将环形带26的一部分夹到衬底支座22。将环形带26固定到支座22至少部分改进了处理结果,因为可在被夹住的带26和支座22之间发生更好的热交换。部分环形带26在衬底处理的过程中能够被过度加热,例如环形带26的顶表面36,其暴露给处理气体的激励等离子。顶表面36的过度加热能够导致环形带26和沉积在环形带26上的任何处理残留物之间的热膨胀不匹配,这可导致处理残留物从顶表面36剥落,并且可能污染衬底104。将环形带26固定到支座22也使带26和支座22之间具有更好的热交换,以改进环形带26的温度控制。例如,通过在支座22中提供包括冷却导管123的温度受控的冷却板127,如在图3中所示的,可对支座22进行温度控制,这样就使被夹住的环形带26得到良好冷却。将环形带26夹到支座22也提供了支座22的更安全的覆盖和保护。环形带26的改进的温度控制也允许利用更抗腐蚀的金属材料(例如不锈钢、钛或铝)来制造所述带。

包括夹具34的衬底环部件20的一个实施例示于图1A和图1B中。在这个实施例中,环形带26包括至少一个延伸穿过其中的开口38,例如从环形带26的顶表面36延伸到环形带的底表面42的基本垂直的开口。夹具34包括紧固件40,其形状和尺寸能够穿过开口38,以将环形带固定到支座22。在图1A所示的实施例中,夹具34还包括托架44,其适于承受紧固件40并且将环形带26固定到支座22。托架44能够被衬底支座22支撑,或者连接到衬底支座22,以靠着支座22夹紧环形带26。例如,托架44可包括夹紧表面46,其被支座22的表面,例如外围边缘30的底表面48压紧,以靠着支座22夹紧环形带26,如例如在图1A和图1B中所示的。夹紧表面46也可压紧环形带26的底表面。

紧固件40包括一个适于穿过环形带26的开口38、并连接到托架44的结构,例如至少螺钉、夹子、弹簧或其他连接器结构之一。例如,在一个实施例中,紧固件40可包括带螺纹的螺钉,其适合穿过环形带26中的开口38,并至少部分穿过托架44中的开口39,其中托架44中的开口39包括配套的(complimentary)螺纹,其允许在旋转螺钉时,托架44被紧固在支座22上。同样,可提供所需数量的开口38和紧固件40,以将环形带26固定到支座22。例如,支撑环部件20可包括从大约3个到大约24个的开口38,例如大约8个开口38,其被置于围绕环形带26的所需配置中。在图1A和图1B所示的实施例中,开口38被定位朝向环形带26的外围(periphery)50。开口38延伸穿过环形带26的顶部32和底部42,以将带26固定到衬底支座22。同样,托架44可包括使得托架“锁定”到环形带26上,以更好地固定环形带26的部件。例如,托架44可包括凸起的壁59,其适于压环形带的圆周侧壁63,以将环形带锁入希望的夹紧位置。

在另一个实施例中,夹具34包括旋转紧固件41,其适于将托架44旋入希望的位置,以将环形带26夹紧到支座22,如图1C所示。例如,旋转紧固件41可包括旋转螺母43,其允许托架44被旋入靠着支座22的地方。通过转动旋转紧固件41,旋转紧固件41可允许托架44围绕紧固件41的轴44旋转,以至于,例如通过仅仅旋转紧固件41,如转动紧固件41的顶部47,托架可被旋入或者离开夹紧位置。因此,旋转紧固件41允许快速移去衬底环部件20,例如为了清洗该部件,而基本不需要从托架44移去紧固件41,甚至基本不需要进入环部件20的一部分或在支座22的外围边缘30之下的其他元件。

在一个实施例中,环形带的顶表面36包括一个粗糙表面,其适于减少处理沉积物在支座22和支撑部件20的不希望区域上的沉积。顶表面36希望包括特征52,其形状、尺寸和位置减少了处理残留物在表面36的至少一部分上的沉积。例如,顶表面36可在环形带的外围50阻止处理残留物流向或移向环形带中的一个或多个开口38。顶表面可收集在表面36中的凹坑中的处理残留物,并且阻止这些处理残留物移向衬底104,以减少衬底104的污染。在一个实施例中,顶表面36包括至少一个特征52,特征52包括突起51,其被定形和确定尺寸,以及定位在顶表面36上,以减少处理残留物流向或移向衬底。突起51可包括,例如凸起的环或可在表面36上形成的其他特征52。表面36上的粗糙特征(textured features)52也可包括,例如表面36中的一个或多个槽53或者其他凹坑。粗糙特征52可用本领域技术人员公知的方法制造,例如通过机加工、滚花或蚀刻中的至少一种可以将特征52制入顶表面36中。具有粗糙特征的表面的实施例在例如2004年6月28提交的、Tsai等人(受让人Applied Materials,Inc.)的10880235号美国专利申请中描述,在此通过引用将文献全部并入。

在一个实施例中,环部件20包括支脚54,其从环形带26向下延伸,以压住衬底支座22。支脚54被理想地定形和定尺寸,以压住衬底支座,而基本不在支座20中引入裂缝或裂纹,因此为将带26固定到所述支座提供了改进的结构。例如,如图1A所示,支脚54可包括基本垂直的柱,其从环形带26的顶部32向下延伸,以压住外围边缘30的顶表面56。支脚54理想地在支座20的外围边缘30上基本仅仅施加压力,并且基本没有能够引起外围突出部分的裂缝或裂纹的切应力或其他水平指向的力。支脚54也被理想地定位,使得它基本不压住外围边缘30上的顶角58a或边缘30的易于破裂或碎裂的其他部分。在一个实施例中,支脚54基本只接触外围边缘30的顶表面56,并且覆盖不超过这个外围边缘表面56的大约70%。

环形带26理想地也包括围绕向下延伸的支脚54的凹进表面区域60,其基本不接触支座22的外围边缘30,以减少环形带26在支座22的外围边缘30上的压力。例如,一个或多个凹进区域60可而围绕外围边缘30的顶角58a,以减少在顶角58a上施加的压力大小。衬底环部件20的其他部分也适于减少施加在支座22的外围边缘30上的压力和/或应力大小。例如,托架44可包括凸缘62,其基本仅仅以压力压住外围边缘30,以及围绕外围边缘的底角58b以减少底角58b上的压力的相邻凹进部分64。托架44和环形带支脚54也可以是处于互补的位置,以至于一个对外围边缘30的夹紧力至少部分被另一个抵消。例如,托架44可基本在支脚54压的地方的径直之下压住外围边缘30,所以外围边缘30上的力基本等于外围边缘30之上和之下的力。因此,通过在支座的外围边缘30上基本仅仅施加垂直的压力,并且基本不压住易于破裂或碎裂的支座22的部分,例如外围边缘30的角落58a、b,衬底环部件20适于减少衬底支座22的裂缝或裂纹。

在一个实施例中,衬底环部件20包括盖环70,其至少部分围绕和至少部分覆盖环形带26的外围50,如在图1A、1b和1c中所示的。盖环70包括径向向内延伸的突出部分72,其延伸穿过至少一部分环形带26,以覆盖和保护环形带26的部分。在一个实施例中,盖环70包括向下延伸的突起74,其尺寸和形状被确定,以阻止处理沉积物在环形带26的顶表面36的至少一部分上沉积,例如以阻止处理气体和处理残留物之一在表面36之上流动。突起74可包括,例如在向内延伸的突出部分72的内直径79处的环形凸缘78,其从盖环70的底表面76延伸大约2mm到5mm。在一个实施例中,突起74被定形、定尺寸和定位,使得突起74与环形带26的粗糙顶表面36相配。例如,突起74可向下延伸,并邻接从环形带26的顶表面36伸出的凸起的突起51,以形成盖环70和环形带26之间旋绕的和狭窄的流动路径75,其阻止处理残留物流过突起74。突起74甚至可延伸进入某种凹陷特征中,例如在环形带26的顶表面中的凹槽53,以进一步阻止处理残留物流过或移过表面26。盖环70优选地是由抗腐蚀材料制造的,其可以是金属材料,例如不锈钢和钛中的至少一种。盖环70也可由陶瓷材料制造,例如氧化铝。盖环70也可包括处理残留物可附着的粗糙顶表面。

在又一个实施例中,衬底环部件20包括一个具有弹簧的夹具34,以将环形带26固定到衬底支座22,如图2A和图2B所示。在图2A所示的实施例中,夹具34包括一个径向弹簧80a,其适于在环形带26和支座22之间被压缩,例如螺旋弹簧。例如,径向弹簧80a可在环形带26底部35的内表面82和支座22外围边缘30的侧壁84之间被压缩。在图2A所示的实施例中,径向弹簧80a也可由延伸穿过外围边缘30的支座凸缘86在下面支撑。压缩的径向弹簧80a在环形带26和支座22上施加一个力,其阻挡环形带26的滑动和其他移动,从而将带26固定在适当的位置。

夹具34也可在径向弹簧80a、80b的一个或多个端89a、89b处包括一个滚珠轴承88,以施加压缩力来固定环形带26。例如,滚珠轴承可位于接触环形带26的径向弹簧80a的第一端89a,以增加接触带26的夹具表面面积。滚珠轴承88也使环形带26能够被容易地移走,例如以便允许清洗环形带26,这是通过向环形带26向上施加一个稳定的力,使所述环形带“滚出”支座22来实现的。径向弹簧80a的第二端89b可包括压缩板92,其具有适于压住支座22的外围边缘30的表面面积,以为压缩夹紧提供更大的表面面积。环形带26也可包括在内表面82上的凸起的脊90或凸起,其在当环形带26被固定在支座22上时位于径向弹簧80a之下。通过增加在脊90之上滚动滚珠轴承所必需的弹簧收缩距离,凸起的脊90增加了向上移动带26所需的力。因此在处理过程中,凸起的脊90和径向弹簧夹具34将环形带26固定到支座22,同时也通过施加足够的提升压力允许有效移去环形带26。

在又一个实施例中,夹具34包括弹簧80b,其适于在环形带26和支座22的一部分之间被拉伸,以将环形带26固定到支座22上,如图2B所示。根据所希望的支座构造,弹簧80b可被垂直、径向拉伸。在图2B所示的实施例中,弹簧80b包括第一端94a,其附到环形带26的一部分上,例如环形带26的底部35中的裂缝96。例如裂缝96的形状和尺寸被确定,以在环形带26上提供钩98,其固定弹簧80b的第一端94a。弹簧80b的第一端94a也通过本领域技术人员公知的方法被连到环形带26。支座22可包括支座凸缘86,其延伸穿过外围边缘30,以从下面支撑环形带26。弹簧80b的第二端94b被拉伸,以连接到支座22的夹紧部分99。因此,弹簧80b在环形带26和支座22的夹紧部分99之间被拉伸,以对着支座22拉环形带26。通过钩住支座22的夹紧部分99,可将弹簧80b的第二端94b连接上。

在一个实施例中,弹簧80b的第二端94b被基本将第二端94b固定到支座22的装置附着,例如通过将第二端94b环绕在支座22上的连接杆97,并且第一端94a是可拆卸地固定到环形带26,如图2B中所示。例如,第二端94b可固定到支座22上,使得弹簧80b的第一端94a能够被转进,并且在环形带26的钩98之上被拉伸,以将环形带26固定到支座22上。为了移动环形带26,第一端94a被提升,并提到钩98之上,并且被拉离带26,以从支座22释放带26。或者,弹簧80b可被基本固定到环形带26上面,并且在衬底处理过程中被可的拆卸地固定到支座22。在一个实施例中,在环形带26和支座22之间拉伸的弹簧80b可包括弹簧锁夹子,其可包括具有高弹簧常数的金属弯形带材,而且高弹簧常数要足够高以便抵带材的伸直,因此在带26上施加朝向支座22的力。在另一个实施例中,弹簧80b包括在环形带26和支座22之间拉伸的螺旋弹簧。

图3示出了一个合适的处理腔106的实例,其具有衬底环部件,环形带26在支座22上面。腔106可以是多腔平台的一部分,该平台具有一组由机械手机构连接的互连腔,机械手在腔106之间传送衬底104。在所示的实施例中,处理腔106包括溅射沉积室,也被称为物理气相沉积或者PVD腔,其能够将沉积材料例如钽、氮化钽、钛、氮化钛、铜、钨、氮化钨和铝中的一种或多种溅射到衬底104上。腔106包括围壁118,其包围处理区109,并且包括侧壁164、底壁166和顶版168。支承环130可排列在侧壁164和顶板168之间,以支撑顶板168。其他的腔壁可包括一个或多个遮护板120,其为围壁118遮避溅射环境。

腔106包括衬底支座22,以在溅射沉积室106中支撑衬底104。衬底支座22可以是电浮动的,或者可包括电极170,其被电源172例如RF电源偏置。衬底支座22也可包括可移动的遮挡桌133,其能够在没有衬底104时保护支座22的上表面134。在操作中,衬底104通过腔106的侧壁164中的衬底装载入口(未示出)被引入腔106,并且被放置在支座22上。支座22可被下面的支座升降机抬起或降低,并且提升指部件(未示出)在将衬底104送入送出腔106的过程中可被用于抬起或降低支座22上的衬底。

腔106可进一步包括温度控制系统119,以控制腔106中的一个或多个温度,例如支座22的温度。在一个实施例中,温度控制系统119包括流体供应源,其适于从流体源121提供热交换流体给支座22,一个或多个导管123将热交换流体从流体源121输送到支座22。支座22可包括一个或多个通道125在其中,例如金属冷却板127中的通道125,热交换流体流动通过它们,以和支座22交换热量,并且控制支座的温度,例如通过加热或冷却支座22。合适的热交换流体可以是,例如水。控制支座22的温度也可为与支座22有良好的热接触的元件提供良好的温度,例如在支座22的表面134上的衬底104,以及衬底环部件20的夹紧部分。

支座22也可包括衬底环部件20,其包括一个或多个环,例如盖环70和环形带26,环形带26可被称为沉积环,并且覆盖至少支座22的上表面134的一部分,以及例如支座22的外围边缘30的一部分,以阻止腐蚀支座22。环形带26至少部分围绕衬底104,以保护支座22没有被衬底104覆盖的部分。盖环70环绕和覆盖至少一部分环形带26,并且减少颗粒在环形带26和下支座22上的沉积。衬底环部件20进一步包括夹具34,以将环形带26固定到衬底支座22上面。

处理气体,例如溅射气体通过气体输送系统112被引入腔106中,气体输送系统112包括处理气体供应源,其包括一个或多个气体源174,每个气体源馈送具有气体流量控制阀178例如质量流量控制器的导管176,设定流速的气体通过其中。导管176可馈送气体到混合的支管(未示出),在其中气体被混合,以形成所需的处理气体合成物。混合的支管在腔106中馈送具有一个或多个气体出口182的气体分配器。处理气体可包括惰性气体,例如氩或氙,其能够高能地碰撞材料和从靶溅射材料。处理气体也可包括反应气体,例如一种或多种含氧的气体和含氮的气体,其能够和溅射的材料发生反应,以在衬底104上形成层。用过的气体和副产物通过排放口122从腔106排出,排放口122可包括一个或多个排放端口184,其接收用过的处理气体并且将用过的气体传给排放导管186,在导管186中具有节流阀,以控制腔106中的气体压力。排放导管186输送一个或多个排放泵190。典型地,在控106中溅射气体的压力波设置为低于大气压的水平。

溅射腔106进一步包括面向衬底104的表面105的溅射靶124,并且溅射靶包括要溅射到衬底104上的材料,例如至少钛和氮化钛之一。靶124通过环形绝缘环132与腔106电绝缘,并且波连接到电源192。溅射腔106也具有遮护板120,以为腔106的壁118遮蔽溅射的材料。遮护板120可包括类似壁的圆柱形状,其具有上和下遮蔽部分120a、120b,其遮蔽腔106的上区域和下区域。在图3所示的实施例中,遮护板120具有安装到支承环130的上部120a和装配到盖环70的下部120b。夹具遮护板141包括夹紧环,其也提供以将上和下遮蔽部分120a、120b夹紧在一起。也可以提供替代的遮护板配置,例如内和外遮护板。在一个实施例中,一个或多个电源192、靶124和遮护板120作为气体激励器116工作,气体激励器116能够激励溅射气体,以从靶124溅射材料。电源192相对于遮护板120向靶124施加偏压。施加的电压在腔106中产生的电场激励溅射气体,以形成高能碰撞和冲击靶124的等离子,以从靶124溅射材料并且溅射到衬底104上。具有电极170的支座22和支座电极电源172也可作为气体激励器116的一部分工作,朝向衬底104激励和加速从靶124溅射的离子材料。此外,可提供由电源192供电的气体激励线圈135,其位于腔106内,以提供增强的激励气体特性,例如提高的激励气体密度。气体激励线圈135可由线圈支座137支撑,支座137波连到遮护板120或者腔106中的其他壁。

腔106可被控制器194控制,控制器194包括具有指令集的程序代码,以操作腔106的组件来处理腔106中的衬底104。例如,控制器194可包括衬底定位指令集,以操作一个或多个衬底支座22和衬底传送器来在腔106中定位衬底104;气体流量控制指令集,以操作流量控制阀178来调整激励气体到腔106的流量;气体压力控制指令集,以操作排放节流阀188来保持腔106中的压力;气体激励器控制指令集,以操作气体激励器116来调整气体激励的能量水平;温度控制指令集,以控制温度控制系统119来控制腔106中的温度;和处理监视指令集,以监视腔106中的处理。

已经参考某些优选的实施例描述了本发明,但是其他的实施例电是可能的。对本领域技术人员而言明显的是,包括夹具34和环形带26的衬底环部件20可以被用于其他类型的应用中,例如用于蚀刻、CVD和清洁工艺中。也可以使用衬底环部件20和夹具34的其他配置。例如,可提供用于将环形带26固定到支座22的其他方法和配置。因此,所附权利要求的精神和范围不应限于本文所述的优选实施例。

Claims (16)

1.一种衬底环部件,其用于具有带有外围的衬底接收表面和带有顶表面的外围边缘的衬底支座,所述部件包括:

a.环形带,其具有:(i)带有突起和一个或者多个槽的顶表面,(ii)围绕所述衬底支座的所述衬底接收表面的所述外围的内周长,(iii)支脚,其从所述环形带向下延伸以接触并压住所述衬底支座的所述外围边缘的不超过70%的所述顶表面,和(iv)围绕向下延伸的支脚的凹进表面区域,其不接触所述衬底支座的所述外围边缘;和

b.夹具,其将所述环形带固定到所述衬底支座的外围边缘。

2.根据权利要求1所述的部件,其中所述环形带包括至少一个垂直地穿过其中的开口,并且其中所述夹具包括:

i.至少一个紧固件,其适于穿过所述环形带中的开口,和

ii.托架,其适于容纳所述紧固件,并将所述环形带固定到所述衬底支座。

3.根据权利要求2所述的部件,其中所述紧固件包括旋转紧固件,其能够旋转所述托架,以靠着所述衬底支座来支撑所述托架。

4.根据权利要求3所述的部件,进一步包括盖环,其围绕所述环形带的外围,并且具有在所述环形带外围之上向内延伸的突出部分,所述突出部分包括向下延伸的突起,该突起被定形和定尺寸,以减少处理沉积物在所述衬底支座的所述外围边缘的所述顶表面的至少一部分上的沉积。

5.根据权利要求4所述的部件,其中所述盖环包括不锈钢、钛和氧化铝中的至少一种。

6.根据权利要求1所述的部件,其中所述夹具包括:

a.径向弹簧,其在所述环形带的内部和所述衬底支座的外围边缘之间被压缩,以将所述环形带固定到所述衬底支座;或者

b.弹簧,其适于在所述环形带和所述衬底支座的一部分之间被拉伸,以将所述环形带固定到所述衬底支座的外围边缘。

7.根据权利要求1所述的部件,其中所述环形带包括不锈钢、钛和铝中的至少一种。

8.一种衬底处理腔,其包括权利要求1所述的衬底环部件,且进一步包括衬底支座、气体输送系统、气体激励器和气体排放口。

9.一种衬底环部件,其用于具有带有外围的衬底接收表面和带有顶表面的外围边缘的衬底支座,所述部件包括:

a.环形带,其内周长至少部分地围绕所述衬底支座的所述衬底接收表面的所述外围,所述环形带包括具有至少一个突起的顶表面,所述突起适于阻止处理沉积物在所述环形带的所述顶表面的至少一部分上沉积;和

b.支脚,其从所述环形带向下延伸,所述支脚适于接触并压住所述衬底支座的所述外围边缘的不超过70%的所述顶表面。

10.根据权利要求9所述的部件,进一步包括夹具,其包括至少一个紧固件,该紧固件适于穿过所述环形带中的垂直开口,并且其进一步包括托架,以容纳所述紧固件,并且将所述环形带固定到所述衬底支座。

11.根据权利要求10所述的部件,其中所述紧固件包括旋转紧固件,其能够旋转所述托架,以靠着所述衬底支座支撑所述托架。

12.根据权利要求9所述的部件,进一步包括盖环,其围绕所述环形带的外围,并且具有在所述环形带外围之上向内延伸的突出部分,所述突出部分包括向下延伸的突起,该突起被定形和定尺寸,以减少处理沉积物在所述环形带的顶表面的至少一部分上的沉积。

13.根据权利要求12所述的部件,其中所述盖环包括不锈钢、钛和氧化铝中的至少一种。

14.根据权利要求9所述的部件,其中所述环形带包括凹进的表面区域,其环绕向下延伸的支脚,并且不接触所述外围边缘。

15.一种衬底环部件,其用于具有带有外围的衬底接收表面和带有顶表面的外围边缘的衬底支座,所述部件包括:

a.环形带,其具有:(i)内周长,其围绕所述衬底支座的所述衬底接收表面的所述外围,和(ii)顶表面,其具有适于阻止处理沉积物在所述环形带的所述顶表面的至少一部分上沉积的至少一个突起,和

b.支脚,其从所述环形带向下延伸,所述支脚被定形、定尺寸和定位,以当所述环形带被固定到所述衬底支座时,使所述环形带在所述衬底支座上施加压力。

16.根据权利要求15所述的部件,其中所述环形带包括围绕所述支脚的凹进的表面区域,其不接触所述衬底支座的外围边缘,且至少一个凹进的区域在所述外围边缘的顶角的周围被定形、定尺寸和定位,以致所述顶角不接触所述环形带。

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US10/981,261 US7670436B2 (en) | 2004-11-03 | 2004-11-03 | Support ring assembly |

| US10/981,261 | 2004-11-03 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN1790659A CN1790659A (zh) | 2006-06-21 |

| CN100437969C true CN100437969C (zh) | 2008-11-26 |

Family

ID=36260375

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CNB2005101174961A Active CN100437969C (zh) | 2004-11-03 | 2005-11-02 | 支承环部件 |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US7670436B2 (zh) |

| JP (1) | JP4808467B2 (zh) |

| KR (1) | KR101267466B1 (zh) |

| CN (1) | CN100437969C (zh) |

| TW (1) | TWI328267B (zh) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN105940143A (zh) * | 2014-01-30 | 2016-09-14 | 应用材料公司 | 用于消除遮蔽框架的气体限制器组件 |

Families Citing this family (56)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7910218B2 (en) | 2003-10-22 | 2011-03-22 | Applied Materials, Inc. | Cleaning and refurbishing chamber components having metal coatings |

| US20060237043A1 (en) * | 2005-04-25 | 2006-10-26 | Applied Materials, Inc. | Method and apparatus for cleaning semiconductor substrates |

| US8617672B2 (en) | 2005-07-13 | 2013-12-31 | Applied Materials, Inc. | Localized surface annealing of components for substrate processing chambers |

| US7762114B2 (en) | 2005-09-09 | 2010-07-27 | Applied Materials, Inc. | Flow-formed chamber component having a textured surface |

| US20070071583A1 (en) * | 2005-09-29 | 2007-03-29 | Stats Chippac Ltd. | Substrate indexing system |

| US7736528B2 (en) * | 2005-10-12 | 2010-06-15 | Panasonic Corporation | Plasma processing apparatus and plasma processing method |

| US20070283884A1 (en) * | 2006-05-30 | 2007-12-13 | Applied Materials, Inc. | Ring assembly for substrate processing chamber |

| JP4609669B2 (ja) * | 2006-06-27 | 2011-01-12 | モメンティブ・パフォーマンス・マテリアルズ・ジャパン合同会社 | 静電チャックモジュール |

| US8221602B2 (en) * | 2006-12-19 | 2012-07-17 | Applied Materials, Inc. | Non-contact process kit |

| WO2008079722A2 (en) * | 2006-12-19 | 2008-07-03 | Applied Materials, Inc. | Non-contact process kit |

| US7981262B2 (en) * | 2007-01-29 | 2011-07-19 | Applied Materials, Inc. | Process kit for substrate processing chamber |

| KR101397124B1 (ko) * | 2007-02-28 | 2014-05-19 | 주성엔지니어링(주) | 기판지지프레임 및 이를 포함하는 기판처리장치, 이를이용한 기판의 로딩 및 언로딩 방법 |

| US7942969B2 (en) | 2007-05-30 | 2011-05-17 | Applied Materials, Inc. | Substrate cleaning chamber and components |

| CN101328571B (zh) * | 2007-06-22 | 2012-01-25 | 中芯国际集成电路制造(上海)有限公司 | 物理气相沉积装置及其维护方法 |

| US20090050272A1 (en) * | 2007-08-24 | 2009-02-26 | Applied Materials, Inc. | Deposition ring and cover ring to extend process components life and performance for process chambers |

| US9062379B2 (en) | 2008-04-16 | 2015-06-23 | Applied Materials, Inc. | Wafer processing deposition shielding components |

| KR20150136142A (ko) * | 2008-04-16 | 2015-12-04 | 어플라이드 머티어리얼스, 인코포레이티드 | 웨이퍼 프로세싱 증착 차폐 컴포넌트들 |

| EP2329521A4 (en) * | 2008-09-26 | 2012-12-26 | Lam Res Corp | ADJUSTABLE THERMAL CONTACT BETWEEN AN ELECTROSTATIC MANDARIN AND A HOT EDGE RING BY SYNCHRONIZATION OF A COUPLING RING. |

| US20100122655A1 (en) * | 2008-11-14 | 2010-05-20 | Tiner Robin L | Ball supported shadow frame |

| CN203103267U (zh) * | 2010-01-29 | 2013-07-31 | 应用材料公司 | 屏蔽件和处理套件 |

| US8920564B2 (en) * | 2010-07-02 | 2014-12-30 | Applied Materials, Inc. | Methods and apparatus for thermal based substrate processing with variable temperature capability |

| KR20130095276A (ko) * | 2010-08-20 | 2013-08-27 | 어플라이드 머티어리얼스, 인코포레이티드 | 수명이 연장된 증착 링 |

| KR101585883B1 (ko) * | 2010-10-29 | 2016-01-15 | 어플라이드 머티어리얼스, 인코포레이티드 | 물리적 기상 증착 챔버를 위한 증착 링 및 정전 척 |

| US9719169B2 (en) * | 2010-12-20 | 2017-08-01 | Novellus Systems, Inc. | System and apparatus for flowable deposition in semiconductor fabrication |

| US9905443B2 (en) * | 2011-03-11 | 2018-02-27 | Applied Materials, Inc. | Reflective deposition rings and substrate processing chambers incorporating same |

| JP5654939B2 (ja) * | 2011-04-20 | 2015-01-14 | 株式会社アルバック | 成膜装置 |

| US9376752B2 (en) * | 2012-04-06 | 2016-06-28 | Applied Materials, Inc. | Edge ring for a deposition chamber |

| JP2014080645A (ja) * | 2012-10-15 | 2014-05-08 | I Plant:Kk | 基板保持装置 |

| US10727092B2 (en) | 2012-10-17 | 2020-07-28 | Applied Materials, Inc. | Heated substrate support ring |

| WO2014159222A1 (en) * | 2013-03-14 | 2014-10-02 | Applied Materials, Inc. | Methods and apparatus for processing a substrate using a selectively grounded and movable process kit ring |

| WO2015023329A1 (en) * | 2013-08-10 | 2015-02-19 | Applied Materials, Inc. | A method of polishing a new or a refurbished electrostatic chuck |

| US9799497B2 (en) * | 2013-08-16 | 2017-10-24 | Taiwan Semiconductor Manufacturing Company Limited | Patterned processing kits for material processing |

| US9847222B2 (en) | 2013-10-25 | 2017-12-19 | Lam Research Corporation | Treatment for flowable dielectric deposition on substrate surfaces |

| CN104862660B (zh) | 2014-02-24 | 2017-10-13 | 北京北方华创微电子装备有限公司 | 承载装置及等离子体加工设备 |

| WO2015188879A1 (en) * | 2014-06-13 | 2015-12-17 | Applied Materials, Inc. | Flat edge design for better uniformity and increased edge lifetime |

| US10049921B2 (en) | 2014-08-20 | 2018-08-14 | Lam Research Corporation | Method for selectively sealing ultra low-k porous dielectric layer using flowable dielectric film formed from vapor phase dielectric precursor |

| JP2016184610A (ja) * | 2015-03-25 | 2016-10-20 | 株式会社東芝 | 上部電極、エッジリングおよびプラズマ処理装置 |

| GB201511282D0 (en) | 2015-06-26 | 2015-08-12 | Spts Technologies Ltd | Plasma etching apparatus |

| CN117867462A (zh) * | 2015-07-03 | 2024-04-12 | 应用材料公司 | 具有高沉积环及沉积环夹具的处理配件 |

| US9916977B2 (en) | 2015-11-16 | 2018-03-13 | Lam Research Corporation | Low k dielectric deposition via UV driven photopolymerization |

| US10388546B2 (en) | 2015-11-16 | 2019-08-20 | Lam Research Corporation | Apparatus for UV flowable dielectric |

| CN106702342B (zh) * | 2015-11-17 | 2019-01-29 | 宁波江丰电子材料股份有限公司 | 用于靶材溅射工艺的压紧环 |

| US10651015B2 (en) * | 2016-02-12 | 2020-05-12 | Lam Research Corporation | Variable depth edge ring for etch uniformity control |

| US11043364B2 (en) * | 2017-06-05 | 2021-06-22 | Applied Materials, Inc. | Process kit for multi-cathode processing chamber |

| CN109023287A (zh) * | 2017-06-08 | 2018-12-18 | 北京北方华创微电子装备有限公司 | 沉积环及卡盘组件 |

| CN109256357B (zh) * | 2017-07-13 | 2020-06-19 | 北京北方华创微电子装备有限公司 | 高温静电卡盘 |

| CN109837518B (zh) * | 2017-11-28 | 2021-06-08 | 北京北方华创微电子装备有限公司 | 沉积环固定组件、承载装置及反应腔室 |

| US20190272983A1 (en) * | 2018-03-01 | 2019-09-05 | Varian Semiconductor Equipment Associates, Inc. | Substrate halo arrangement for improved process uniformity |

| US11594445B2 (en) | 2018-03-13 | 2023-02-28 | Applied Materials, Inc. | Support ring with plasma spray coating |

| US10411448B1 (en) * | 2018-08-20 | 2019-09-10 | Siemens Industry, Inc. | Ring assembly of radially-concentric rings with quick fastening mechanism to detachably connect such rings to one another |

| US11551965B2 (en) | 2018-12-07 | 2023-01-10 | Applied Materials, Inc. | Apparatus to reduce polymers deposition |

| CN113166927B (zh) * | 2018-12-17 | 2023-07-28 | 应用材料公司 | 用于pvd腔室的具有高沉积环的处理配件 |

| USD933726S1 (en) | 2020-07-31 | 2021-10-19 | Applied Materials, Inc. | Deposition ring for a semiconductor processing chamber |

| US11581166B2 (en) | 2020-07-31 | 2023-02-14 | Applied Materials, Inc. | Low profile deposition ring for enhanced life |

| TWI749935B (zh) * | 2020-12-03 | 2021-12-11 | 天虹科技股份有限公司 | 用以產生穩定偏壓的晶圓承載盤及應用該晶圓承載盤的薄膜沉積設備 |

| US11915918B2 (en) | 2021-06-29 | 2024-02-27 | Applied Materials, Inc. | Cleaning of sin with CCP plasma or RPS clean |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6159299A (en) * | 1999-02-09 | 2000-12-12 | Applied Materials, Inc. | Wafer pedestal with a purge ring |

| US20020029745A1 (en) * | 2000-04-25 | 2002-03-14 | Toshifumi Nagaiwa | Worktable device and plasma processing apparatus for semiconductor process |

| US20020076490A1 (en) * | 2000-12-15 | 2002-06-20 | Chiang Tony P. | Variable gas conductance control for a process chamber |

| US6620736B2 (en) * | 2001-07-24 | 2003-09-16 | Tokyo Electron Limited | Electrostatic control of deposition of, and etching by, ionized materials in semiconductor processing |

| US20040074761A1 (en) * | 2002-10-22 | 2004-04-22 | Applied Materials, Inc. | Plating uniformity control by contact ring shaping |

Family Cites Families (198)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3482082A (en) | 1966-03-18 | 1969-12-02 | Techicon Corp | Sample identification apparatus |

| US3679460A (en) | 1970-10-08 | 1972-07-25 | Union Carbide Corp | Composite wear resistant material and method of making same |

| US4384918A (en) | 1980-09-30 | 1983-05-24 | Fujitsu Limited | Method and apparatus for dry etching and electrostatic chucking device used therein |

| US4419201A (en) | 1981-08-24 | 1983-12-06 | Bell Telephone Laboratories, Incorporated | Apparatus and method for plasma-assisted etching of wafers |

| US4412133A (en) | 1982-01-05 | 1983-10-25 | The Perkin-Elmer Corp. | Electrostatic cassette |

| JPS6059104B2 (ja) | 1982-02-03 | 1985-12-23 | 株式会社東芝 | 静電チヤツク板 |

| FR2538987A1 (fr) | 1983-01-05 | 1984-07-06 | Commissariat Energie Atomique | Enceinte pour le traitement et notamment la gravure de substrats par la methode du plasma reactif |

| GB2147459A (en) | 1983-09-30 | 1985-05-09 | Philips Electronic Associated | Electrostatic chuck for semiconductor wafers |

| US4606802A (en) | 1983-12-21 | 1986-08-19 | Hitachi, Ltd. | Planar magnetron sputtering with modified field configuration |

| JPS6131636U (ja) | 1984-07-31 | 1986-02-26 | 株式会社 徳田製作所 | 静電チヤツク |

| US5215639A (en) | 1984-10-09 | 1993-06-01 | Genus, Inc. | Composite sputtering target structures and process for producing such structures |

| DE3523958A1 (de) | 1985-07-04 | 1987-01-08 | Licentia Gmbh | Verfahren zur chemischen behandlung von keramikkoerpern mit nachfolgender metallisierung |

| JP2515731B2 (ja) | 1985-10-25 | 1996-07-10 | 株式会社日立製作所 | 薄膜形成装置および薄膜形成方法 |

| US4684447A (en) | 1986-03-24 | 1987-08-04 | Conoco Inc. | Method for applying protective coatings |

| CH670970A5 (zh) | 1986-09-18 | 1989-07-31 | Grob Ernst Fa | |

| US4832781A (en) | 1988-01-07 | 1989-05-23 | Varian Associates, Inc. | Methods and apparatus for thermal transfer with a semiconductor wafer in vacuum |

| ATE95513T1 (de) | 1988-04-26 | 1993-10-15 | Toto Ltd | Verfahren zur herstellung dielektrischer keramik fuer elektrostatische haltevorrichtungen. |

| JP2665242B2 (ja) | 1988-09-19 | 1997-10-22 | 東陶機器株式会社 | 静電チャック |

| JP2807675B2 (ja) * | 1988-11-30 | 1998-10-08 | 東京エレクトロン株式会社 | レジスト処理装置 |

| US5409590A (en) | 1989-04-17 | 1995-04-25 | Materials Research Corporation | Target cooling and support for magnetron sputter coating apparatus |

| JP2779950B2 (ja) | 1989-04-25 | 1998-07-23 | 東陶機器株式会社 | 静電チャックの電圧印加方法および電圧印加装置 |

| US4995958A (en) | 1989-05-22 | 1991-02-26 | Varian Associates, Inc. | Sputtering apparatus with a rotating magnet array having a geometry for specified target erosion profile |

| IT1235332B (it) | 1989-06-05 | 1992-06-26 | Diaprint S P A | Granitura elettrochimica di superfici in alluminio o in lega di alluminio |

| DE69103915T2 (de) | 1990-01-25 | 1995-05-11 | Applied Materials Inc | Elektrostatische Klemmvorrichtung und Verfahren. |

| US5391275A (en) | 1990-03-02 | 1995-02-21 | Applied Materials, Inc. | Method for preparing a shield to reduce particles in a physical vapor deposition chamber |

| US5055964A (en) | 1990-09-07 | 1991-10-08 | International Business Machines Corporation | Electrostatic chuck having tapered electrodes |

| JP3064409B2 (ja) | 1990-11-30 | 2000-07-12 | 株式会社日立製作所 | 保持装置およびそれを用いた半導体製造装置 |

| EP0493089B1 (en) | 1990-12-25 | 1998-09-16 | Ngk Insulators, Ltd. | Wafer heating apparatus and method for producing the same |

| US5166856A (en) | 1991-01-31 | 1992-11-24 | International Business Machines Corporation | Electrostatic chuck with diamond coating |

| US5191506A (en) | 1991-05-02 | 1993-03-02 | International Business Machines Corporation | Ceramic electrostatic chuck |

| US5325261A (en) | 1991-05-17 | 1994-06-28 | Unisearch Limited | Electrostatic chuck with improved release |

| US5458759A (en) | 1991-08-02 | 1995-10-17 | Anelva Corporation | Magnetron sputtering cathode apparatus |

| US5275683A (en) | 1991-10-24 | 1994-01-04 | Tokyo Electron Limited | Mount for supporting substrates and plasma processing apparatus using the same |

| US5539609A (en) | 1992-12-02 | 1996-07-23 | Applied Materials, Inc. | Electrostatic chuck usable in high density plasma |

| JPH05166757A (ja) | 1991-12-13 | 1993-07-02 | Tokyo Electron Ltd | 被処理体の温調装置 |

| EP0547609B1 (en) | 1991-12-18 | 1997-09-10 | Sumitomo Metal Industries, Ltd. | Automobile body panel made of multilayer plated aluminum sheet |

| US5376223A (en) | 1992-01-09 | 1994-12-27 | Varian Associates, Inc. | Plasma etch process |

| US5315473A (en) | 1992-01-21 | 1994-05-24 | Applied Materials, Inc. | Isolated electrostatic chuck and excitation method |

| JP2865472B2 (ja) | 1992-02-20 | 1999-03-08 | 信越化学工業株式会社 | 静電チャック |

| US5314597A (en) | 1992-03-20 | 1994-05-24 | Varian Associates, Inc. | Sputtering apparatus with a magnet array having a geometry for a specified target erosion profile |

| FR2692599B1 (fr) | 1992-06-17 | 1994-09-16 | Prod Ind Cfpi Franc | Procédé de traitement de substrats à base d'aluminium en vue de leur anodisation, bain mis en Óoeuvre dans ce procédé et concentré pour préparer le bain. |

| JP2938679B2 (ja) | 1992-06-26 | 1999-08-23 | 信越化学工業株式会社 | セラミックス製静電チャック |

| US5401319A (en) | 1992-08-27 | 1995-03-28 | Applied Materials, Inc. | Lid and door for a vacuum chamber and pretreatment therefor |

| US6338906B1 (en) | 1992-09-17 | 2002-01-15 | Coorstek, Inc. | Metal-infiltrated ceramic seal |

| JP2839801B2 (ja) | 1992-09-18 | 1998-12-16 | 三菱マテリアル株式会社 | ウェーハの製造方法 |

| US5684669A (en) | 1995-06-07 | 1997-11-04 | Applied Materials, Inc. | Method for dechucking a workpiece from an electrostatic chuck |

| US5350479A (en) | 1992-12-02 | 1994-09-27 | Applied Materials, Inc. | Electrostatic chuck for high power plasma processing |

| US5542559A (en) | 1993-02-16 | 1996-08-06 | Tokyo Electron Kabushiki Kaisha | Plasma treatment apparatus |

| JPH06326175A (ja) | 1993-04-22 | 1994-11-25 | Applied Materials Inc | 集積回路処理装置において使用されるウエハサポートの誘電材への保護被覆とその形成方法 |

| CH690805A5 (de) | 1993-05-04 | 2001-01-15 | Unaxis Balzers Ag | Magnetfeldunterstützte Zerstäubungsanordnung und Vakuumbehandlungsanlage hiermit. |

| US5403459A (en) | 1993-05-17 | 1995-04-04 | Applied Materials, Inc. | Cleaning of a PVD chamber containing a collimator |

| US5407551A (en) | 1993-07-13 | 1995-04-18 | The Boc Group, Inc. | Planar magnetron sputtering apparatus |

| US5433835B1 (en) | 1993-11-24 | 1997-05-20 | Applied Materials Inc | Sputtering device and target with cover to hold cooling fluid |

| US6199259B1 (en) | 1993-11-24 | 2001-03-13 | Applied Komatsu Technology, Inc. | Autoclave bonding of sputtering target assembly |

| US5487822A (en) | 1993-11-24 | 1996-01-30 | Applied Materials, Inc. | Integrated sputtering target assembly |

| US5463526A (en) | 1994-01-21 | 1995-10-31 | Lam Research Corporation | Hybrid electrostatic chuck |

| US5474649A (en) | 1994-03-08 | 1995-12-12 | Applied Materials, Inc. | Plasma processing apparatus employing a textured focus ring |

| US5512078A (en) | 1994-03-24 | 1996-04-30 | Griffin; Stephen E. | Apparatus for making linearly tapered bores in quartz tubing with a controlled laser |

| US5685914A (en) * | 1994-04-05 | 1997-11-11 | Applied Materials, Inc. | Focus ring for semiconductor wafer processing in a plasma reactor |

| JP2720420B2 (ja) | 1994-04-06 | 1998-03-04 | キヤノン販売株式会社 | 成膜/エッチング装置 |

| DE4446919A1 (de) | 1994-12-28 | 1996-07-04 | Dynamit Nobel Ag | Verfahren zur Herstellung von innenverzahnten Teilen |

| JP2689931B2 (ja) | 1994-12-29 | 1997-12-10 | 日本電気株式会社 | スパッタ方法 |

| US5792562A (en) | 1995-01-12 | 1998-08-11 | Applied Materials, Inc. | Electrostatic chuck with polymeric impregnation and method of making |

| US6073830A (en) | 1995-04-21 | 2000-06-13 | Praxair S.T. Technology, Inc. | Sputter target/backing plate assembly and method of making same |

| US5886863A (en) | 1995-05-09 | 1999-03-23 | Kyocera Corporation | Wafer support member |

| US5695825A (en) | 1995-05-31 | 1997-12-09 | Amorphous Technologies International | Titanium-containing ferrous hard-facing material source and method for hard facing a substrate |

| US6221217B1 (en) | 1995-07-10 | 2001-04-24 | Cvc, Inc. | Physical vapor deposition system having reduced thickness backing plate |

| WO1997003221A1 (en) | 1995-07-10 | 1997-01-30 | Cvc Products, Inc. | Magnetron cathode apparatus and method for sputtering |

| KR100227924B1 (ko) | 1995-07-28 | 1999-11-01 | 가이데 히사오 | 반도체 웨이퍼 제조방법, 그 방법에 사용되는 연삭방법 및 이에 사용되는 장치 |

| JP3457477B2 (ja) | 1995-09-06 | 2003-10-20 | 日本碍子株式会社 | 静電チャック |

| US5805408A (en) * | 1995-12-22 | 1998-09-08 | Lam Research Corporation | Electrostatic clamp with lip seal for clamping substrates |

| JPH09270401A (ja) | 1996-01-31 | 1997-10-14 | Shin Etsu Handotai Co Ltd | 半導体ウェーハの研磨方法 |

| JPH09270400A (ja) | 1996-01-31 | 1997-10-14 | Shin Etsu Handotai Co Ltd | 半導体ウェーハの製造方法 |

| US5879524A (en) | 1996-02-29 | 1999-03-09 | Sony Corporation | Composite backing plate for a sputtering target |

| JP3620554B2 (ja) | 1996-03-25 | 2005-02-16 | 信越半導体株式会社 | 半導体ウェーハ製造方法 |

| US5720818A (en) | 1996-04-26 | 1998-02-24 | Applied Materials, Inc. | Conduits for flow of heat transfer fluid to the surface of an electrostatic chuck |

| EP0803900A3 (en) | 1996-04-26 | 1999-12-29 | Applied Materials, Inc. | Surface preparation to enhance the adhesion of a dielectric layer |

| US6108189A (en) | 1996-04-26 | 2000-08-22 | Applied Materials, Inc. | Electrostatic chuck having improved gas conduits |

| US6440221B2 (en) | 1996-05-13 | 2002-08-27 | Applied Materials, Inc. | Process chamber having improved temperature control |

| US5948288A (en) | 1996-05-28 | 1999-09-07 | Komag, Incorporated | Laser disk texturing apparatus |

| US5824197A (en) | 1996-06-05 | 1998-10-20 | Applied Materials, Inc. | Shield for a physical vapor deposition chamber |

| US5812362A (en) | 1996-06-14 | 1998-09-22 | Applied Materials, Inc. | Method and apparatus for the use of diamond films as dielectric coatings on electrostatic chucks |

| US5736021A (en) | 1996-07-10 | 1998-04-07 | Applied Materials, Inc. | Electrically floating shield in a plasma reactor |

| US5914018A (en) | 1996-08-23 | 1999-06-22 | Applied Materials, Inc. | Sputter target for eliminating redeposition on the target sidewall |

| US6143432A (en) | 1998-01-09 | 2000-11-07 | L. Pierre deRochemont | Ceramic composites with improved interfacial properties and methods to make such composites |

| US5916454A (en) | 1996-08-30 | 1999-06-29 | Lam Research Corporation | Methods and apparatus for reducing byproduct particle generation in a plasma processing chamber |

| US5942041A (en) | 1996-09-16 | 1999-08-24 | Mosel-Vitelic, Inc. | Non-sticking semi-conductor wafer clamp and method of making same |

| US6007673A (en) | 1996-10-02 | 1999-12-28 | Matsushita Electronics Corporation | Apparatus and method of producing an electronic device |

| US5830327A (en) | 1996-10-02 | 1998-11-03 | Intevac, Inc. | Methods and apparatus for sputtering with rotating magnet sputter sources |

| US5685959A (en) | 1996-10-25 | 1997-11-11 | Hmt Technology Corporation | Cathode assembly having rotating magnetic-field shunt and method of making magnetic recording media |

| US6284093B1 (en) * | 1996-11-29 | 2001-09-04 | Applied Materials, Inc. | Shield or ring surrounding semiconductor workpiece in plasma chamber |

| US6152071A (en) | 1996-12-11 | 2000-11-28 | Canon Kabushiki Kaisha | High-frequency introducing means, plasma treatment apparatus, and plasma treatment method |

| US5821166A (en) | 1996-12-12 | 1998-10-13 | Komatsu Electronic Metals Co., Ltd. | Method of manufacturing semiconductor wafers |

| US6120640A (en) | 1996-12-19 | 2000-09-19 | Applied Materials, Inc. | Boron carbide parts and coatings in a plasma reactor |

| EP0946965B1 (de) | 1996-12-21 | 2006-05-17 | Singulus Technologies AG | Vorrichtung und verfahren zur kathodenzerstäubung |

| WO1998031845A1 (en) | 1997-01-16 | 1998-07-23 | Bottomfield, Layne, F. | Vapor deposition components and corresponding methods |

| US5963778A (en) | 1997-02-13 | 1999-10-05 | Tosoh Smd, Inc. | Method for producing near net shape planar sputtering targets and an intermediate therefor |

| US5808270A (en) | 1997-02-14 | 1998-09-15 | Ford Global Technologies, Inc. | Plasma transferred wire arc thermal spray apparatus and method |

| US5844318A (en) | 1997-02-18 | 1998-12-01 | Micron Technology, Inc. | Aluminum film for semiconductive devices |

| US5916378A (en) | 1997-03-11 | 1999-06-29 | Wj Semiconductor Equipment Group, Inc. | Method of reducing metal contamination during semiconductor processing in a reactor having metal components |

| DE19719133C2 (de) | 1997-05-07 | 1999-09-02 | Heraeus Quarzglas | Glocke aus Quarzglas und Verfahren für ihre Herstellung |

| US6051114A (en) | 1997-06-23 | 2000-04-18 | Applied Materials, Inc. | Use of pulsed-DC wafer bias for filling vias/trenches with metal in HDP physical vapor deposition |

| US6162297A (en) | 1997-09-05 | 2000-12-19 | Applied Materials, Inc. | Embossed semiconductor fabrication parts |

| US6010583A (en) | 1997-09-09 | 2000-01-04 | Sony Corporation | Method of making unreacted metal/aluminum sputter target |

| US5903428A (en) | 1997-09-25 | 1999-05-11 | Applied Materials, Inc. | Hybrid Johnsen-Rahbek electrostatic chuck having highly resistive mesas separating the chuck from a wafer supported thereupon and method of fabricating same |

| US5879523A (en) | 1997-09-29 | 1999-03-09 | Applied Materials, Inc. | Ceramic coated metallic insulator particularly useful in a plasma sputter reactor |

| US5920764A (en) | 1997-09-30 | 1999-07-06 | International Business Machines Corporation | Process for restoring rejected wafers in line for reuse as new |

| JPH11131254A (ja) | 1997-10-24 | 1999-05-18 | Nippon Parkerizing Co Ltd | アルミニウム含有金属材料の表面処理方法 |

| US5953827A (en) | 1997-11-05 | 1999-09-21 | Applied Materials, Inc. | Magnetron with cooling system for process chamber of processing system |

| US5976327A (en) | 1997-12-12 | 1999-11-02 | Applied Materials, Inc. | Step coverage and overhang improvement by pedestal bias voltage modulation |

| JP3179075B2 (ja) | 1997-12-22 | 2001-06-25 | 旭化成株式会社 | 電気植毛用の繊維及び電気植毛品 |

| US6340415B1 (en) | 1998-01-05 | 2002-01-22 | Applied Materials, Inc. | Method and apparatus for enhancing a sputtering target's lifetime |

| US6579431B1 (en) | 1998-01-14 | 2003-06-17 | Tosoh Smd, Inc. | Diffusion bonding of high purity metals and metal alloys to aluminum backing plates using nickel or nickel alloy interlayers |

| KR100265289B1 (ko) | 1998-01-26 | 2000-09-15 | 윤종용 | 플라즈마식각장치의 캐소우드 제조방법 및 이에 따라 제조되는 캐소우드 |

| JP3271658B2 (ja) | 1998-03-23 | 2002-04-02 | 信越半導体株式会社 | 半導体シリコン単結晶ウェーハのラップ又は研磨方法 |

| JP3483494B2 (ja) | 1998-03-31 | 2004-01-06 | キヤノン株式会社 | 真空処理装置および真空処理方法、並びに該方法によって作成される電子写真感光体 |

| US6015465A (en) | 1998-04-08 | 2000-01-18 | Applied Materials, Inc. | Temperature control system for semiconductor process chamber |

| JP3500063B2 (ja) | 1998-04-23 | 2004-02-23 | 信越半導体株式会社 | 剥離ウエーハを再利用する方法および再利用に供されるシリコンウエーハ |

| US6086735A (en) | 1998-06-01 | 2000-07-11 | Praxair S.T. Technology, Inc. | Contoured sputtering target |

| DE19830817B4 (de) | 1998-07-09 | 2011-06-09 | Leifeld Metal Spinning Gmbh | Verfahren zum Umformen eines Werkstücks durch Drückwalzen |

| US6183686B1 (en) | 1998-08-04 | 2001-02-06 | Tosoh Smd, Inc. | Sputter target assembly having a metal-matrix-composite backing plate and methods of making same |

| US6071389A (en) | 1998-08-21 | 2000-06-06 | Tosoh Smd, Inc. | Diffusion bonded sputter target assembly and method of making |

| US6749103B1 (en) | 1998-09-11 | 2004-06-15 | Tosoh Smd, Inc. | Low temperature sputter target bonding method and target assemblies produced thereby |

| KR100292410B1 (ko) * | 1998-09-23 | 2001-06-01 | 윤종용 | 불순물 오염이 억제된 반도체 제조용 반응 챔버 |

| US6170429B1 (en) | 1998-09-30 | 2001-01-09 | Lam Research Corporation | Chamber liner for semiconductor process chambers |

| US6238528B1 (en) | 1998-10-13 | 2001-05-29 | Applied Materials, Inc. | Plasma density modulator for improved plasma density uniformity and thickness uniformity in an ionized metal plasma source |

| JP2000124092A (ja) | 1998-10-16 | 2000-04-28 | Shin Etsu Handotai Co Ltd | 水素イオン注入剥離法によってsoiウエーハを製造する方法およびこの方法で製造されたsoiウエーハ |

| WO2000028104A1 (en) | 1998-11-06 | 2000-05-18 | Scivac | Sputtering apparatus and process for high rate coatings |

| US6447853B1 (en) | 1998-11-30 | 2002-09-10 | Kawasaki Microelectronics, Inc. | Method and apparatus for processing semiconductor substrates |

| US6276997B1 (en) | 1998-12-23 | 2001-08-21 | Shinhwa Li | Use of chemical mechanical polishing and/or poly-vinyl-acetate scrubbing to restore quality of used semiconductor wafers |

| JP4141560B2 (ja) | 1998-12-28 | 2008-08-27 | 日本メクトロン株式会社 | 回路基板のプラズマ処理装置 |

| US6183614B1 (en) | 1999-02-12 | 2001-02-06 | Applied Materials, Inc. | Rotating sputter magnetron assembly |

| KR100343136B1 (ko) | 1999-03-18 | 2002-07-05 | 윤종용 | 이중 연마저지층을 이용한 화학기계적 연마방법 |

| US6500321B1 (en) | 1999-05-26 | 2002-12-31 | Novellus Systems, Inc. | Control of erosion profile and process characteristics in magnetron sputtering by geometrical shaping of the sputtering target |

| US6146509A (en) | 1999-06-11 | 2000-11-14 | Scivac | Inverted field circular magnetron sputtering device |

| US6352620B2 (en) | 1999-06-28 | 2002-03-05 | Applied Materials, Inc. | Staged aluminum deposition process for filling vias |

| KR100315088B1 (ko) * | 1999-09-29 | 2001-11-24 | 윤종용 | 포커스 링을 갖는 반도체 웨이퍼 제조 장치 |

| US6423175B1 (en) | 1999-10-06 | 2002-07-23 | Taiwan Semiconductor Manufacturing Co., Ltd | Apparatus and method for reducing particle contamination in an etcher |

| US6190516B1 (en) | 1999-10-06 | 2001-02-20 | Praxair S.T. Technology, Inc. | High magnetic flux sputter targets with varied magnetic permeability in selected regions |

| US6149784A (en) | 1999-10-22 | 2000-11-21 | Applied Materials, Inc. | Sputtering chamber shield promoting reliable plasma ignition |

| US6299740B1 (en) | 2000-01-19 | 2001-10-09 | Veeco Instrument, Inc. | Sputtering assembly and target therefor |

| US6780794B2 (en) | 2000-01-20 | 2004-08-24 | Honeywell International Inc. | Methods of bonding physical vapor deposition target materials to backing plate materials |

| US6277249B1 (en) | 2000-01-21 | 2001-08-21 | Applied Materials Inc. | Integrated process for copper via filling using a magnetron and target producing highly energetic ions |

| US6227435B1 (en) | 2000-02-02 | 2001-05-08 | Ford Global Technologies, Inc. | Method to provide a smooth paintable surface after aluminum joining |

| JP2002181050A (ja) | 2000-03-16 | 2002-06-26 | Nsk Ltd | 転がり摺動部材とその製造方法及び転がり摺動ユニット |

| US6416634B1 (en) | 2000-04-05 | 2002-07-09 | Applied Materials, Inc. | Method and apparatus for reducing target arcing during sputter deposition |

| US6287437B1 (en) | 2000-05-05 | 2001-09-11 | Alcatel | Recessed bonding of target for RF diode sputtering |

| US6619537B1 (en) | 2000-06-12 | 2003-09-16 | Tosoh Smd, Inc. | Diffusion bonding of copper sputtering targets to backing plates using nickel alloy interlayers |

| US6627050B2 (en) | 2000-07-28 | 2003-09-30 | Applied Materials, Inc. | Method and apparatus for depositing a tantalum-containing layer on a substrate |

| US6506289B2 (en) | 2000-08-07 | 2003-01-14 | Symmorphix, Inc. | Planar optical devices and methods for their manufacture |

| DE60142299D1 (de) | 2000-08-17 | 2010-07-15 | Tosoh Smd Inc | Hochreiner sputtering targets mit indikator zur anzeige des endes der nutzungsdauerfür target und herstellungsverfahren dafür |

| EP1322444A4 (en) | 2000-09-11 | 2008-01-23 | Tosoh Smd Inc | METHOD FOR MANUFACTURING CATHODIC SPUTTER TARGETS WITH INTERNAL COOLING CHANNELS |

| US6475336B1 (en) * | 2000-10-06 | 2002-11-05 | Lam Research Corporation | Electrostatically clamped edge ring for plasma processing |

| US6858116B2 (en) | 2000-11-17 | 2005-02-22 | Nikko Materials Company, Limited | Sputtering target producing few particles, backing plate or sputtering apparatus and sputtering method producing few particles |

| US6916407B2 (en) | 2000-11-27 | 2005-07-12 | Unaxis Trading Ag | Target comprising thickness profiling for an RF magnetron |

| US20020090464A1 (en) | 2000-11-28 | 2002-07-11 | Mingwei Jiang | Sputter chamber shield |

| KR100817742B1 (ko) | 2000-12-18 | 2008-03-31 | 토소우 에스엠디, 인크 | 스퍼터 타겟 조립체의 제조방법 및 타겟 조립체 |

| US6805952B2 (en) | 2000-12-29 | 2004-10-19 | Lam Research Corporation | Low contamination plasma chamber components and methods for making the same |

| JP2002220661A (ja) | 2001-01-29 | 2002-08-09 | Sharp Corp | スパッタリング装置に用いられるバッキングプレートおよびスパッタリング方法 |

| US6576909B2 (en) | 2001-02-28 | 2003-06-10 | International Business Machines Corp. | Ion generation chamber |

| JP4209198B2 (ja) | 2001-04-24 | 2009-01-14 | トーソー エスエムディー,インク. | ターゲット、およびターゲットプロファイルを最適化する方法 |

| US6599405B2 (en) | 2001-05-30 | 2003-07-29 | Praxair S.T. Technology, Inc. | Recessed sputter target |

| US6777045B2 (en) | 2001-06-27 | 2004-08-17 | Applied Materials Inc. | Chamber components having textured surfaces and method of manufacture |

| US20030047464A1 (en) | 2001-07-27 | 2003-03-13 | Applied Materials, Inc. | Electrochemically roughened aluminum semiconductor processing apparatus surfaces |

| US6656535B2 (en) | 2001-12-21 | 2003-12-02 | Applied Materials, Inc | Method of fabricating a coated process chamber component |

| US6899798B2 (en) | 2001-12-21 | 2005-05-31 | Applied Materials, Inc. | Reusable ceramic-comprising component which includes a scrificial surface layer |

| KR100446623B1 (ko) | 2002-01-30 | 2004-09-04 | 삼성에스디아이 주식회사 | 전계 방출 표시장치 및 그 제조방법 |

| US6743340B2 (en) * | 2002-02-05 | 2004-06-01 | Applied Materials, Inc. | Sputtering of aligned magnetic materials and magnetic dipole ring used therefor |

| KR20030071926A (ko) | 2002-03-02 | 2003-09-13 | 엘지.필립스 엘시디 주식회사 | 스퍼터링 타겟 어셈블리 및 이를 이용한 스퍼터링 장비 |

| US6623610B1 (en) | 2002-03-02 | 2003-09-23 | Shinzo Onishi | Magnetron sputtering target for magnetic materials |

| US6730174B2 (en) | 2002-03-06 | 2004-05-04 | Applied Materials, Inc. | Unitary removable shield assembly |

| US6933508B2 (en) | 2002-03-13 | 2005-08-23 | Applied Materials, Inc. | Method of surface texturizing |

| US6812471B2 (en) | 2002-03-13 | 2004-11-02 | Applied Materials, Inc. | Method of surface texturizing |

| US7026009B2 (en) | 2002-03-27 | 2006-04-11 | Applied Materials, Inc. | Evaluation of chamber components having textured coatings |

| TWI269815B (en) | 2002-05-20 | 2007-01-01 | Tosoh Smd Inc | Replaceable target sidewall insert with texturing |

| US6708870B2 (en) | 2002-05-24 | 2004-03-23 | Praxair S.T. Technology, Inc. | Method for forming sputter target assemblies |

| US6652668B1 (en) | 2002-05-31 | 2003-11-25 | Praxair S.T. Technology, Inc. | High-purity ferromagnetic sputter targets and method of manufacture |

| FR2842648B1 (fr) | 2002-07-18 | 2005-01-14 | Commissariat Energie Atomique | Procede de transfert d'une couche mince electriquement active |

| WO2004038062A2 (en) | 2002-10-21 | 2004-05-06 | Cabot Corporation | Method of forming a sputtering target assembly and assembly made therefrom |

| US6902628B2 (en) | 2002-11-25 | 2005-06-07 | Applied Materials, Inc. | Method of cleaning a coated process chamber component |

| US20040261946A1 (en) * | 2003-04-24 | 2004-12-30 | Tokyo Electron Limited | Plasma processing apparatus, focus ring, and susceptor |

| JP2007523993A (ja) | 2003-06-20 | 2007-08-23 | キャボット コーポレイション | スパッタターゲットをバッキングプレートに結合させるための方法及び設計 |

| US6992261B2 (en) | 2003-07-15 | 2006-01-31 | Cabot Corporation | Sputtering target assemblies using resistance welding |

| US7425093B2 (en) | 2003-07-16 | 2008-09-16 | Cabot Corporation | Thermography test method and apparatus for bonding evaluation in sputtering targets |

| US20050061857A1 (en) | 2003-09-24 | 2005-03-24 | Hunt Thomas J. | Method for bonding a sputter target to a backing plate and the assembly thereof |

| US7431195B2 (en) | 2003-09-26 | 2008-10-07 | Praxair S.T. Technology, Inc. | Method for centering a sputter target onto a backing plate and the assembly thereof |

| JP2007520634A (ja) | 2004-02-03 | 2007-07-26 | ハネウェル・インターナショナル・インコーポレーテッド | 物理蒸着用ターゲット構造物 |

| US20050178653A1 (en) | 2004-02-17 | 2005-08-18 | Charles Fisher | Method for elimination of sputtering into the backing plate of a target/backing plate assembly |

| US7018515B2 (en) | 2004-03-24 | 2006-03-28 | Applied Materials, Inc. | Selectable dual position magnetron |

| US20060188742A1 (en) | 2005-01-18 | 2006-08-24 | Applied Materials, Inc. | Chamber component having grooved surface |

| US20060005767A1 (en) | 2004-06-28 | 2006-01-12 | Applied Materials, Inc. | Chamber component having knurled surface |

| ATE546561T1 (de) | 2004-11-19 | 2012-03-15 | Applied Materials Gmbh & Co Kg | Trägerplatte mit einer darauf aufgesetzten gekühlten rückenplatte |

| US7644745B2 (en) | 2005-06-06 | 2010-01-12 | Applied Materials, Inc. | Bonding of target tiles to backing plate with patterned bonding agent |

| US9127362B2 (en) | 2005-10-31 | 2015-09-08 | Applied Materials, Inc. | Process kit and target for substrate processing chamber |

| US8647484B2 (en) | 2005-11-25 | 2014-02-11 | Applied Materials, Inc. | Target for sputtering chamber |

| US20070215463A1 (en) | 2006-03-14 | 2007-09-20 | Applied Materials, Inc. | Pre-conditioning a sputtering target prior to sputtering |

| US7981262B2 (en) | 2007-01-29 | 2011-07-19 | Applied Materials, Inc. | Process kit for substrate processing chamber |

| US20080257263A1 (en) | 2007-04-23 | 2008-10-23 | Applied Materials, Inc. | Cooling shield for substrate processing chamber |

-

2004

- 2004-11-03 US US10/981,261 patent/US7670436B2/en active Active

-

2005

- 2005-10-28 TW TW094137903A patent/TWI328267B/zh active

- 2005-11-02 CN CNB2005101174961A patent/CN100437969C/zh active Active

- 2005-11-03 KR KR1020050104893A patent/KR101267466B1/ko active IP Right Grant

- 2005-11-04 JP JP2005320823A patent/JP4808467B2/ja active Active

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6159299A (en) * | 1999-02-09 | 2000-12-12 | Applied Materials, Inc. | Wafer pedestal with a purge ring |

| US20020029745A1 (en) * | 2000-04-25 | 2002-03-14 | Toshifumi Nagaiwa | Worktable device and plasma processing apparatus for semiconductor process |

| US20020076490A1 (en) * | 2000-12-15 | 2002-06-20 | Chiang Tony P. | Variable gas conductance control for a process chamber |

| US6620736B2 (en) * | 2001-07-24 | 2003-09-16 | Tokyo Electron Limited | Electrostatic control of deposition of, and etching by, ionized materials in semiconductor processing |

| US20040074761A1 (en) * | 2002-10-22 | 2004-04-22 | Applied Materials, Inc. | Plating uniformity control by contact ring shaping |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN105940143A (zh) * | 2014-01-30 | 2016-09-14 | 应用材料公司 | 用于消除遮蔽框架的气体限制器组件 |

| CN105940143B (zh) * | 2014-01-30 | 2019-11-08 | 应用材料公司 | 用于消除遮蔽框架的气体限制器组件 |

| US11773489B2 (en) | 2014-01-30 | 2023-10-03 | Applied Materials, Inc. | Gas confiner assembly for eliminating shadow frame |

Also Published As

| Publication number | Publication date |

|---|---|

| US7670436B2 (en) | 2010-03-02 |

| TW200629461A (en) | 2006-08-16 |

| JP2006140473A (ja) | 2006-06-01 |

| KR20060052443A (ko) | 2006-05-19 |

| KR101267466B1 (ko) | 2013-05-31 |

| TWI328267B (en) | 2010-08-01 |

| CN1790659A (zh) | 2006-06-21 |

| JP4808467B2 (ja) | 2011-11-02 |

| US20060090706A1 (en) | 2006-05-04 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN100437969C (zh) | 支承环部件 | |

| US7697260B2 (en) | Detachable electrostatic chuck | |

| KR101410921B1 (ko) | 기판 프로세싱 챔버를 위한 링 조립체 | |

| TWI503444B (zh) | 半導體基板處理方法 | |

| US6450117B1 (en) | Directing a flow of gas in a substrate processing chamber | |

| CN201025611Y (zh) | 用于衬底处理室的带状屏蔽 | |

| KR200483057Y1 (ko) | 물리 기상 증착 챔버를 위한 실드, 스퍼터링 타겟의 스퍼터링 표면을 에워싸기 위한 실드, 및 프로세스 키트 | |

| CN101688291B (zh) | 用于基板处理腔室的冷却遮蔽件 | |

| US6830624B2 (en) | Blocker plate by-pass for remote plasma clean | |

| JP6660971B2 (ja) | シャドーフレームサポート | |

| US6223447B1 (en) | Fastening device for a purge ring | |

| US20050241579A1 (en) | Face shield to improve uniformity of blanket CVD processes | |

| CN101916715A (zh) | 用于前段工艺制造的原地干洗腔 | |

| JP2003163208A (ja) | セルフクリーニングを実行するプラズマcvd装置及び方法 | |

| JP2001512905A (ja) | 高温処理チャンバ用のセラミック被覆された加熱アセンブリ | |

| EP0601656B1 (en) | Device for the treatment of substrates at low temperature | |

| KR102205922B1 (ko) | 공정에서의 워크피스 상의 재료 증착 방지 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant |