CN1276046C - 硅氧烷基粘合片材、将半导体芯片粘接到芯片连接元件上的方法,和半导体器件 - Google Patents

硅氧烷基粘合片材、将半导体芯片粘接到芯片连接元件上的方法,和半导体器件 Download PDFInfo

- Publication number

- CN1276046C CN1276046C CNB038168367A CN03816836A CN1276046C CN 1276046 C CN1276046 C CN 1276046C CN B038168367 A CNB038168367 A CN B038168367A CN 03816836 A CN03816836 A CN 03816836A CN 1276046 C CN1276046 C CN 1276046C

- Authority

- CN

- China

- Prior art keywords

- layer

- argillaceous

- composition

- silicone compositions

- curable silicone

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/67—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere

- H01L21/683—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping

- H01L21/6835—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping using temporarily an auxiliary support

- H01L21/6836—Wafer tapes, e.g. grinding or dicing support tapes

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/04—Manufacture or treatment of semiconductor devices or of parts thereof the devices having at least one potential-jump barrier or surface barrier, e.g. PN junction, depletion layer or carrier concentration layer

- H01L21/50—Assembly of semiconductor devices using processes or apparatus not provided for in a single one of the subgroups H01L21/06 - H01L21/326, e.g. sealing of a cap to a base of a container

- H01L21/52—Mounting semiconductor bodies in containers

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J183/00—Adhesives based on macromolecular compounds obtained by reactions forming in the main chain of the macromolecule a linkage containing silicon, with or without sulfur, nitrogen, oxygen, or carbon only; Adhesives based on derivatives of such polymers

- C09J183/04—Polysiloxanes

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J5/00—Adhesive processes in general; Adhesive processes not provided for elsewhere, e.g. relating to primers

- C09J5/06—Adhesive processes in general; Adhesive processes not provided for elsewhere, e.g. relating to primers involving heating of the applied adhesive

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J7/00—Adhesives in the form of films or foils

- C09J7/30—Adhesives in the form of films or foils characterised by the adhesive composition

- C09J7/35—Heat-activated

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/04—Manufacture or treatment of semiconductor devices or of parts thereof the devices having at least one potential-jump barrier or surface barrier, e.g. PN junction, depletion layer or carrier concentration layer

- H01L21/50—Assembly of semiconductor devices using processes or apparatus not provided for in a single one of the subgroups H01L21/06 - H01L21/326, e.g. sealing of a cap to a base of a container

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L24/00—Arrangements for connecting or disconnecting semiconductor or solid-state bodies; Methods or apparatus related thereto

- H01L24/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L24/26—Layer connectors, e.g. plate connectors, solder or adhesive layers; Manufacturing methods related thereto

- H01L24/27—Manufacturing methods

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L24/00—Arrangements for connecting or disconnecting semiconductor or solid-state bodies; Methods or apparatus related thereto

- H01L24/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L24/26—Layer connectors, e.g. plate connectors, solder or adhesive layers; Manufacturing methods related thereto

- H01L24/28—Structure, shape, material or disposition of the layer connectors prior to the connecting process

- H01L24/29—Structure, shape, material or disposition of the layer connectors prior to the connecting process of an individual layer connector

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L24/00—Arrangements for connecting or disconnecting semiconductor or solid-state bodies; Methods or apparatus related thereto

- H01L24/80—Methods for connecting semiconductor or other solid state bodies using means for bonding being attached to, or being formed on, the surface to be connected

- H01L24/83—Methods for connecting semiconductor or other solid state bodies using means for bonding being attached to, or being formed on, the surface to be connected using a layer connector

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L83/00—Compositions of macromolecular compounds obtained by reactions forming in the main chain of the macromolecule a linkage containing silicon with or without sulfur, nitrogen, oxygen or carbon only; Compositions of derivatives of such polymers

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J2203/00—Applications of adhesives in processes or use of adhesives in the form of films or foils

- C09J2203/326—Applications of adhesives in processes or use of adhesives in the form of films or foils for bonding electronic components such as wafers, chips or semiconductors

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J2301/00—Additional features of adhesives in the form of films or foils

- C09J2301/10—Additional features of adhesives in the form of films or foils characterized by the structural features of the adhesive tape or sheet

- C09J2301/12—Additional features of adhesives in the form of films or foils characterized by the structural features of the adhesive tape or sheet by the arrangement of layers

- C09J2301/124—Additional features of adhesives in the form of films or foils characterized by the structural features of the adhesive tape or sheet by the arrangement of layers the adhesive layer being present on both sides of the carrier, e.g. double-sided adhesive tape

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J2483/00—Presence of polysiloxane

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2221/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof covered by H01L21/00

- H01L2221/67—Apparatus for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components; Apparatus not specifically provided for elsewhere

- H01L2221/683—Apparatus for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components; Apparatus not specifically provided for elsewhere for supporting or gripping

- H01L2221/68304—Apparatus for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components; Apparatus not specifically provided for elsewhere for supporting or gripping using temporarily an auxiliary support

- H01L2221/68327—Apparatus for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components; Apparatus not specifically provided for elsewhere for supporting or gripping using temporarily an auxiliary support used during dicing or grinding

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L2224/26—Layer connectors, e.g. plate connectors, solder or adhesive layers; Manufacturing methods related thereto

- H01L2224/27—Manufacturing methods

- H01L2224/274—Manufacturing methods by blanket deposition of the material of the layer connector

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L2224/26—Layer connectors, e.g. plate connectors, solder or adhesive layers; Manufacturing methods related thereto

- H01L2224/28—Structure, shape, material or disposition of the layer connectors prior to the connecting process

- H01L2224/29—Structure, shape, material or disposition of the layer connectors prior to the connecting process of an individual layer connector

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L2224/26—Layer connectors, e.g. plate connectors, solder or adhesive layers; Manufacturing methods related thereto

- H01L2224/28—Structure, shape, material or disposition of the layer connectors prior to the connecting process

- H01L2224/29—Structure, shape, material or disposition of the layer connectors prior to the connecting process of an individual layer connector

- H01L2224/29001—Core members of the layer connector

- H01L2224/29099—Material

- H01L2224/2919—Material with a principal constituent of the material being a polymer, e.g. polyester, phenolic based polymer, epoxy

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L2224/26—Layer connectors, e.g. plate connectors, solder or adhesive layers; Manufacturing methods related thereto

- H01L2224/28—Structure, shape, material or disposition of the layer connectors prior to the connecting process

- H01L2224/29—Structure, shape, material or disposition of the layer connectors prior to the connecting process of an individual layer connector

- H01L2224/29001—Core members of the layer connector

- H01L2224/29099—Material

- H01L2224/2919—Material with a principal constituent of the material being a polymer, e.g. polyester, phenolic based polymer, epoxy

- H01L2224/29191—The principal constituent being an elastomer, e.g. silicones, isoprene, neoprene

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L2224/26—Layer connectors, e.g. plate connectors, solder or adhesive layers; Manufacturing methods related thereto

- H01L2224/28—Structure, shape, material or disposition of the layer connectors prior to the connecting process

- H01L2224/29—Structure, shape, material or disposition of the layer connectors prior to the connecting process of an individual layer connector

- H01L2224/29001—Core members of the layer connector

- H01L2224/29099—Material

- H01L2224/29198—Material with a principal constituent of the material being a combination of two or more materials in the form of a matrix with a filler, i.e. being a hybrid material, e.g. segmented structures, foams

- H01L2224/29298—Fillers

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L2224/26—Layer connectors, e.g. plate connectors, solder or adhesive layers; Manufacturing methods related thereto

- H01L2224/31—Structure, shape, material or disposition of the layer connectors after the connecting process

- H01L2224/32—Structure, shape, material or disposition of the layer connectors after the connecting process of an individual layer connector

- H01L2224/321—Disposition

- H01L2224/32135—Disposition the layer connector connecting between different semiconductor or solid-state bodies, i.e. chip-to-chip

- H01L2224/32145—Disposition the layer connector connecting between different semiconductor or solid-state bodies, i.e. chip-to-chip the bodies being stacked

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L2224/26—Layer connectors, e.g. plate connectors, solder or adhesive layers; Manufacturing methods related thereto

- H01L2224/31—Structure, shape, material or disposition of the layer connectors after the connecting process

- H01L2224/32—Structure, shape, material or disposition of the layer connectors after the connecting process of an individual layer connector

- H01L2224/321—Disposition

- H01L2224/32151—Disposition the layer connector connecting between a semiconductor or solid-state body and an item not being a semiconductor or solid-state body, e.g. chip-to-substrate, chip-to-passive

- H01L2224/32221—Disposition the layer connector connecting between a semiconductor or solid-state body and an item not being a semiconductor or solid-state body, e.g. chip-to-substrate, chip-to-passive the body and the item being stacked

- H01L2224/32225—Disposition the layer connector connecting between a semiconductor or solid-state body and an item not being a semiconductor or solid-state body, e.g. chip-to-substrate, chip-to-passive the body and the item being stacked the item being non-metallic, e.g. insulating substrate with or without metallisation

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L2224/42—Wire connectors; Manufacturing methods related thereto

- H01L2224/44—Structure, shape, material or disposition of the wire connectors prior to the connecting process

- H01L2224/45—Structure, shape, material or disposition of the wire connectors prior to the connecting process of an individual wire connector

- H01L2224/45001—Core members of the connector

- H01L2224/4501—Shape

- H01L2224/45012—Cross-sectional shape

- H01L2224/45015—Cross-sectional shape being circular

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L2224/42—Wire connectors; Manufacturing methods related thereto

- H01L2224/44—Structure, shape, material or disposition of the wire connectors prior to the connecting process

- H01L2224/45—Structure, shape, material or disposition of the wire connectors prior to the connecting process of an individual wire connector

- H01L2224/45001—Core members of the connector

- H01L2224/45099—Material

- H01L2224/451—Material with a principal constituent of the material being a metal or a metalloid, e.g. boron (B), silicon (Si), germanium (Ge), arsenic (As), antimony (Sb), tellurium (Te) and polonium (Po), and alloys thereof

- H01L2224/45117—Material with a principal constituent of the material being a metal or a metalloid, e.g. boron (B), silicon (Si), germanium (Ge), arsenic (As), antimony (Sb), tellurium (Te) and polonium (Po), and alloys thereof the principal constituent melting at a temperature of greater than or equal to 400°C and less than 950°C

- H01L2224/45124—Aluminium (Al) as principal constituent

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L2224/42—Wire connectors; Manufacturing methods related thereto

- H01L2224/44—Structure, shape, material or disposition of the wire connectors prior to the connecting process

- H01L2224/45—Structure, shape, material or disposition of the wire connectors prior to the connecting process of an individual wire connector

- H01L2224/45001—Core members of the connector

- H01L2224/45099—Material

- H01L2224/451—Material with a principal constituent of the material being a metal or a metalloid, e.g. boron (B), silicon (Si), germanium (Ge), arsenic (As), antimony (Sb), tellurium (Te) and polonium (Po), and alloys thereof

- H01L2224/45138—Material with a principal constituent of the material being a metal or a metalloid, e.g. boron (B), silicon (Si), germanium (Ge), arsenic (As), antimony (Sb), tellurium (Te) and polonium (Po), and alloys thereof the principal constituent melting at a temperature of greater than or equal to 950°C and less than 1550°C

- H01L2224/45139—Silver (Ag) as principal constituent

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L2224/42—Wire connectors; Manufacturing methods related thereto

- H01L2224/44—Structure, shape, material or disposition of the wire connectors prior to the connecting process

- H01L2224/45—Structure, shape, material or disposition of the wire connectors prior to the connecting process of an individual wire connector

- H01L2224/45001—Core members of the connector

- H01L2224/45099—Material

- H01L2224/451—Material with a principal constituent of the material being a metal or a metalloid, e.g. boron (B), silicon (Si), germanium (Ge), arsenic (As), antimony (Sb), tellurium (Te) and polonium (Po), and alloys thereof

- H01L2224/45138—Material with a principal constituent of the material being a metal or a metalloid, e.g. boron (B), silicon (Si), germanium (Ge), arsenic (As), antimony (Sb), tellurium (Te) and polonium (Po), and alloys thereof the principal constituent melting at a temperature of greater than or equal to 950°C and less than 1550°C

- H01L2224/45144—Gold (Au) as principal constituent

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L2224/42—Wire connectors; Manufacturing methods related thereto

- H01L2224/47—Structure, shape, material or disposition of the wire connectors after the connecting process

- H01L2224/48—Structure, shape, material or disposition of the wire connectors after the connecting process of an individual wire connector

- H01L2224/4805—Shape

- H01L2224/4809—Loop shape

- H01L2224/48091—Arched

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L2224/42—Wire connectors; Manufacturing methods related thereto

- H01L2224/47—Structure, shape, material or disposition of the wire connectors after the connecting process

- H01L2224/48—Structure, shape, material or disposition of the wire connectors after the connecting process of an individual wire connector

- H01L2224/481—Disposition

- H01L2224/48151—Connecting between a semiconductor or solid-state body and an item not being a semiconductor or solid-state body, e.g. chip-to-substrate, chip-to-passive

- H01L2224/48221—Connecting between a semiconductor or solid-state body and an item not being a semiconductor or solid-state body, e.g. chip-to-substrate, chip-to-passive the body and the item being stacked

- H01L2224/48225—Connecting between a semiconductor or solid-state body and an item not being a semiconductor or solid-state body, e.g. chip-to-substrate, chip-to-passive the body and the item being stacked the item being non-metallic, e.g. insulating substrate with or without metallisation

- H01L2224/48227—Connecting between a semiconductor or solid-state body and an item not being a semiconductor or solid-state body, e.g. chip-to-substrate, chip-to-passive the body and the item being stacked the item being non-metallic, e.g. insulating substrate with or without metallisation connecting the wire to a bond pad of the item

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/73—Means for bonding being of different types provided for in two or more of groups H01L2224/10, H01L2224/18, H01L2224/26, H01L2224/34, H01L2224/42, H01L2224/50, H01L2224/63, H01L2224/71

- H01L2224/732—Location after the connecting process

- H01L2224/73251—Location after the connecting process on different surfaces

- H01L2224/73265—Layer and wire connectors

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/80—Methods for connecting semiconductor or other solid state bodies using means for bonding being attached to, or being formed on, the surface to be connected

- H01L2224/83—Methods for connecting semiconductor or other solid state bodies using means for bonding being attached to, or being formed on, the surface to be connected using a layer connector

- H01L2224/8319—Arrangement of the layer connectors prior to mounting

- H01L2224/83191—Arrangement of the layer connectors prior to mounting wherein the layer connectors are disposed only on the semiconductor or solid-state body

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/80—Methods for connecting semiconductor or other solid state bodies using means for bonding being attached to, or being formed on, the surface to be connected

- H01L2224/83—Methods for connecting semiconductor or other solid state bodies using means for bonding being attached to, or being formed on, the surface to be connected using a layer connector

- H01L2224/8319—Arrangement of the layer connectors prior to mounting

- H01L2224/83194—Lateral distribution of the layer connectors

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/80—Methods for connecting semiconductor or other solid state bodies using means for bonding being attached to, or being formed on, the surface to be connected

- H01L2224/83—Methods for connecting semiconductor or other solid state bodies using means for bonding being attached to, or being formed on, the surface to be connected using a layer connector

- H01L2224/838—Bonding techniques

- H01L2224/8385—Bonding techniques using a polymer adhesive, e.g. an adhesive based on silicone, epoxy, polyimide, polyester

- H01L2224/83855—Hardening the adhesive by curing, i.e. thermosetting

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/80—Methods for connecting semiconductor or other solid state bodies using means for bonding being attached to, or being formed on, the surface to be connected

- H01L2224/85—Methods for connecting semiconductor or other solid state bodies using means for bonding being attached to, or being formed on, the surface to be connected using a wire connector

- H01L2224/852—Applying energy for connecting

- H01L2224/85201—Compression bonding

- H01L2224/85205—Ultrasonic bonding

- H01L2224/85207—Thermosonic bonding

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L24/00—Arrangements for connecting or disconnecting semiconductor or solid-state bodies; Methods or apparatus related thereto

- H01L24/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L24/42—Wire connectors; Manufacturing methods related thereto

- H01L24/44—Structure, shape, material or disposition of the wire connectors prior to the connecting process

- H01L24/45—Structure, shape, material or disposition of the wire connectors prior to the connecting process of an individual wire connector

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L24/00—Arrangements for connecting or disconnecting semiconductor or solid-state bodies; Methods or apparatus related thereto

- H01L24/73—Means for bonding being of different types provided for in two or more of groups H01L24/10, H01L24/18, H01L24/26, H01L24/34, H01L24/42, H01L24/50, H01L24/63, H01L24/71

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/0001—Technical content checked by a classifier

- H01L2924/00013—Fully indexed content

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/01—Chemical elements

- H01L2924/01005—Boron [B]

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/01—Chemical elements

- H01L2924/01006—Carbon [C]

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/01—Chemical elements

- H01L2924/01011—Sodium [Na]

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/01—Chemical elements

- H01L2924/01013—Aluminum [Al]

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/01—Chemical elements

- H01L2924/01014—Silicon [Si]

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/01—Chemical elements

- H01L2924/01015—Phosphorus [P]

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/01—Chemical elements

- H01L2924/01019—Potassium [K]

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/01—Chemical elements

- H01L2924/0102—Calcium [Ca]

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/01—Chemical elements

- H01L2924/01023—Vanadium [V]

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/01—Chemical elements

- H01L2924/01027—Cobalt [Co]

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/01—Chemical elements

- H01L2924/01029—Copper [Cu]

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/01—Chemical elements

- H01L2924/0103—Zinc [Zn]

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/01—Chemical elements

- H01L2924/01033—Arsenic [As]

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/01—Chemical elements

- H01L2924/01038—Strontium [Sr]

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/01—Chemical elements

- H01L2924/01043—Technetium [Tc]

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/01—Chemical elements

- H01L2924/01045—Rhodium [Rh]

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/01—Chemical elements

- H01L2924/01046—Palladium [Pd]

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/01—Chemical elements

- H01L2924/01047—Silver [Ag]

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/01—Chemical elements

- H01L2924/01052—Tellurium [Te]

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/01—Chemical elements

- H01L2924/01078—Platinum [Pt]

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/01—Chemical elements

- H01L2924/01079—Gold [Au]

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/01—Chemical elements

- H01L2924/01082—Lead [Pb]

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/01—Chemical elements

- H01L2924/01092—Uranium [U]

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/06—Polymers

- H01L2924/0665—Epoxy resin

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/06—Polymers

- H01L2924/078—Adhesive characteristics other than chemical

- H01L2924/07802—Adhesive characteristics other than chemical not being an ohmic electrical conductor

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/095—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00 with a principal constituent of the material being a combination of two or more materials provided in the groups H01L2924/013 - H01L2924/0715

- H01L2924/097—Glass-ceramics, e.g. devitrified glass

- H01L2924/09701—Low temperature co-fired ceramic [LTCC]

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/10—Details of semiconductor or other solid state devices to be connected

- H01L2924/102—Material of the semiconductor or solid state bodies

- H01L2924/1025—Semiconducting materials

- H01L2924/10251—Elemental semiconductors, i.e. Group IV

- H01L2924/10253—Silicon [Si]

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/10—Details of semiconductor or other solid state devices to be connected

- H01L2924/11—Device type

- H01L2924/13—Discrete devices, e.g. 3 terminal devices

- H01L2924/1301—Thyristor

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/10—Details of semiconductor or other solid state devices to be connected

- H01L2924/11—Device type

- H01L2924/14—Integrated circuits

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/15—Details of package parts other than the semiconductor or other solid state devices to be connected

- H01L2924/181—Encapsulation

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/19—Details of hybrid assemblies other than the semiconductor or other solid state devices to be connected

- H01L2924/1901—Structure

- H01L2924/1904—Component type

- H01L2924/19043—Component type being a resistor

Abstract

硅氧烷基粘合片材在一侧上具有粘土状可固化硅氧烷组合物层和在另一侧上具有固化速度慢于第一组合物层的粘土状可固化硅氧烷组合物层,或者在一侧上具有固化的硅氧烷层和在另一侧上具有粘土状可固化硅氧烷组合物层。该硅氧烷基粘合片材可在粘接半导体芯片和芯片连接元件的方法中使用。通过该方法可制备半导体器件。

Description

技术领域

本发明涉及硅氧烷基粘合片材,将半导体芯片粘接到芯片连接元件上的方法,和半导体器件。更特别地,本发明涉及硅氧烷基粘合片材,利用它可以以满意的方式粘接光滑的基体和在表面上具有不规则度的基体,和其中可使粘接层的厚度变得几乎均匀。本发明进一步涉及将半导体芯片粘接到芯片连接元件上的方法,其中半导体芯片和芯片连接元件可满意地粘接在一起,即使这两个中的至少一个在表面上具有不规则度。本发明进一步涉及具有优异可靠度的半导体器件,其中半导体芯片和芯片连接元件可满意地粘接在一起,即使这两个中的至少一个在表面上具有不规则度。

背景技术

在日本专利申请特开No.11-12546(相应于美国专利No.6235862)中提出了硅氧烷基粘合片材可用于粘接半导体芯片和芯片连接元件,其中所述硅氧烷基粘合片材是通过固化夹在两个保护膜之间的可氢化硅烷化固化的硅氧烷组合物而获得的。然而,这种片材的问题在于,当在半导体芯片和/或芯片连接元件的表面上出现10微米或更大的不规则度(间隙)时,填充间隙的能力下降和这二者不可能被充分地粘接。

在日本专利申请特开No.10-17828(相应于美国专利No.5942565)中提出了厚度为0.1-5毫米(mm)的粘土状片材粘合剂,它包括有机聚硅氧烷、填料和含有粘合促进剂的硅氧烷组合物。然而,使用该片材粘接一种基体和另一基体的问题在于,粘接层的厚度不均匀。特别地当通过这种片材粘合剂将半导体芯片粘接到芯片连接元件上时,产生粘接层厚度变得不均匀的问题,从而引起随后布线粘接工艺的不便。

因此,本发明的目的是提供硅氧烷基粘合片材,利用它可以以满意的方式粘接光滑的基体和在表面上具有不规则度的基体,和其中可使粘接层的厚度变得几乎均匀;提供将半导体芯片粘接到芯片连接元件上的方法,其中半导体芯片和芯片连接元件可满意地粘接在一起,即使这两个中的至少一个在表面上具有不规则度;和提供具有优异可靠度的半导体器件,其中半导体芯片和芯片连接元件可满意地粘接在一起,即使这两个中的至少一个在表面上具有不规则度。

发明内容

本发明的硅氧烷基粘合片材在该片材的一侧上具有粘土状可固化的硅氧烷组合物层和在该片材的另一侧上具有固化速度慢于第一次提及层的粘土状硅氧烷组合物层,或在一侧上具有固化的硅氧烷层和在另一侧上具有粘土状可固化硅氧烷组合物层。

本发明的将半导体芯片粘接到芯片连接元件上的方法包括步骤(1)通过将层压体切割成小片,生产半导体芯片,其中所述层压体由粘接到晶片上的固化硅氧烷层、牢固地粘接到该固化层上的粘土状可固化硅氧烷组合物层、牢固地粘接到该组合物层上的保护膜和用粘合剂连接到该膜上的片材组成;(2)从芯片中剥离所述保护膜和片材;(3)通过借助组合物层压制半导体芯片到芯片连接元件上,将半导体芯片粘接到芯片连接元件上;和(4)固化该组合物层。

本发明的半导体器件包括硅氧烷基粘合片材,它在一侧上具有粘土状可固化硅氧烷组合物(I)的层,和在另一侧上具有固化速度慢于组合物(I)的层的粘土状可固化硅氧烷组合物(II)的层,从而使(i)组合物(I)的层如此固化,以便在组合物(I)的层保持与半导体芯片接触的同时,组合物(II)的层仍然未固化,和随后在组合物(II)的层保持与半导体芯片连接元件接触的同时组合物(II)的层固化,或从而使(ii)组合物(I)的层如此固化,以便在组合物(I)的层保持与半导体芯片连接元件接触的同时组合物(II)的层仍然未固化,和随后在组合物(II)的层保持与半导体芯片接触的同时,组合物(II)的层固化。

或者,本发明的半导体器件包括硅氧烷基粘合片材,它在一侧上具有固化的硅氧烷层,和在另一侧上具有粘土状可固化硅氧烷组合物层,从而使(i)固化层被如此粘接,以便在固化层保持与半导体芯片接触的同时,组合物层仍然末固化,和随后在组合物层保持与半导体芯片连接元件接触的同时组合物层固化,或从而使(ii)固化层被如此粘接,以便在固化层保持与半导体芯片连接元件接触的同时组合物层仍然未固化,和随后在组合物层保持与半导体芯片接触的同时,组合物层固化。

附图的简要说明

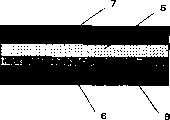

图1是实施例2中生产的本发明硅氧烷基粘合片材的截面视图。

图2是实施例1和实施例3-5生产的本发明硅氧烷基粘合片材的截面视图。

图3是涉及本发明半导体芯片和芯片连接元件粘接方法的实施例6中生产的部分切割晶片的截面视图。

图4是实施例1-6中生产的本发明半导体器件的截面视图。

图5是实施例7中生产的本发明半导体器件的截面视图。

参考标记

1:粘土状可固化硅氧烷组合物层

2:粘土状可固化硅氧烷组合物层

3:保护膜

4:保护膜

5;硅氧烷固化层

6:粘土状可固化硅氧烷组合物层

7:保护膜

8:保护膜

9:晶片

10:硅氧烷固化层

11:粘土状可固化硅氧烷组合物层

12:保护膜

13:粘合片材

14:半导体芯片

15:硅氧烷固化层

16:硅氧烷固化层

17:半导体芯片连接元件

18:粘接线

19:硅氧烷橡胶基粘合层

优选实施方案的详细说明

硅氧烷基粘合片材

图1示出了本发明的硅氧烷基粘合片材。该片材在一侧上具有粘土状可固化硅氧烷组合物层1,和在另一侧上具有固化速度慢于第一次提及层的粘土状硅氧烷组合物层2。这些可固化硅氧烷组合物的固化速度可以例如基于其90%硫化时间{tc(90)}来比较,所述90%硫化时间是根据JIS K 6300的规定,使用振荡硫化测试仪进行的硫化试验中在相同的温度条件(例如130℃,150℃)下测量的。并不限制固化速度之差,但具有低固化速度的可固化硅氧烷组合物的tc(90)与具有高固化速度的可固化硅氧烷组合物的tc(90)之比在130℃下优选5倍或更大,和更优选10倍或更大,或者在150℃下优选2倍或更大,和更优选5倍或更大。

并不限制组合物层1的厚度,但优选100微米(μm)或更低,更优选1-100μm,和甚至更优选1-50μm。也不限制组合物层2的厚度,但优选100微米或更低,更优选1-100μm,和甚至更优选1-50μm。也不限制片材厚度,但优选100微米或更低。

并不限制如JIS K 6249规定的这些粘土状可固化硅氧烷组合物的可塑值,和可以相同或者不同。可塑值均优选在100-800范围内,和更优选在100-700范围内,和甚至更优选在100-500范围内。可塑值是当根据JIS K 6249的技术要求,通过平行板塑性计(William’sPlastimeter),施加49±0.05N的负载到样品{体积为2±0.02cm3的圆柱形物体(直径:16mm,高度:10mm)}上3分钟时的数值。

并不限制通过固化这些粘土状可固化硅氧烷组合物而获得的固化硅氧烷物质的性能,和可以相同或者不同。固化硅氧烷材料优选具有弹性体性能,更优选橡胶性能。并不限制固化这些粘土状可固化硅氧烷组合物的机理,和可相同或不同。可固化硅氧烷组合物的实例包括可氢化硅烷化固化的硅氧烷组合物、可缩合固化的硅氧烷组合物、通过包括有机过氧化物的自由基反应可固化的硅氧烷组合物,和通过高能辐射可固化的硅氧烷组合物。在本发明的硅氧烷基粘合片材中,较慢固化速度的可固化硅氧烷组合物和较快固化速度的可固化硅氧烷组合物均优选可氢化硅烷化固化的硅氧烷组合物。

这些可氢化硅烷化固化的硅氧烷组合物优选是包含(A)每一分子具有至少两个链烯基的有机聚硅氧烷;(B)填料;(C)每一分子具有至少两个与硅键合的氢原子的有机聚硅氧烷;(D)粘合促进剂;和(E)氢化硅烷化催化剂的可固化硅氧烷组合物。

组分(A)是每一分子具有至少两个链烯基的有机聚硅氧烷。组分(A)的重均聚合度优选3000或更大,和其性能优选是天然橡胶的性能。组分(A)的分子结构的实例包括直链结构、部分支化的直链结构、支链结构和网状结构。组分(A)的链烯基的实例包括乙烯基、烯丙基、丁烯基、戊烯基和己烯基,其中尤其优选乙烯基。这些链烯基的键合位置的实例包括分子链的端位和/或分子链的侧链。键合到硅原子上的除了链烯基以外的基团的实例包括取代或未取代的单价烃基如甲基、乙基、丙基、丁基、戊基、己基、庚基和其它这种烷基;苯基、甲苯基、二甲苯基、萘基和其它这种芳基;苄基、苯乙基和其它这种芳烷基;氯代甲基、3-氯丙基、3,3,3-三氟丙基和其它这种卤代烷基,其中尤其优选甲基、苯基和类似基团。当组分(A)含有苯基时,所得片材被赋予优异的耐低温性,和在该片材辅助下将半导体芯片粘接到芯片连接元件上而获得的半导体器件的可靠性可得到改进。

组分(B)是填料,它降低以上提及的组合物的流动性和赋予通过固化以上提及的组合物而获得的固化组合物的机械强度。组分(B)是可与可固化的硅氧烷组合物共同混合的填料,只要不损害本发明的目的即可,和实例包括沉淀二氧化硅、热解法二氧化硅、烘烤二氧化硅、氧化钛、氧化铝、玻璃、石英、硅铝酸盐、氧化铁、氧化锌、碳酸钙、炭黑、碳化硅、氮化硅、氮化硼和其它这种无机填料;通过用有机卤代硅烷、有机烷氧基硅烷、有机硅氮烷和其它这种有机硅化合物处理这些填料而获得的无机填料;硅氧烷树脂、环氧树脂、氟树脂,和其它这种树脂微粉;诸如银、铜之类的填料和其它这种导电金属粉末;和硅氧烷弹性体粉末。尤其优选沉淀二氧化硅、热解法二氧化硅和其它类型的增强二氧化硅,以及胶态碳酸钙、炭黑和其它这种增稠和增韧微粒填料。

在以上提及的组合物中,并不限制组分(B)的含量,但以每100重量份组分(A)计,优选在1-1000重量份范围内,更优选在5-800重量份范围内,甚至更优选在5-500重量份范围内,尤其优选在5-200重量份范围内,和理想地在5-100重量份范围内。特别地,当使用能赋予强度的微粒填料作为组分(B)时,以每100重量份组分(A)计,含量优选在1-100重量份范围内,和更优选在1-50重量份范围内。这是因为当组分(B)的含量小于以上提及的范围的下限时,所得固化产物往往无法被赋予足够的机械强度,而当含量超过以上提及的范围的上限时,往往难以制备均匀的组合物。

组分(C)是以上提及的组合物中的交联剂,和是在每一分子上具有至少两个与硅键合的氢原子的有机聚硅氧烷。组分(C)的分子结构的实例包括直链结构、部分支化的直链结构、支链结构,环结构和网状结构。在组分(C)中,键合到硅原子上的氢原子的键合位置的实例包括分子链的端位或分子链的侧链或者这二者。在组分(C)中,键合到硅原子上的除了氢原子以外的基团的实例包括与前面所述的那些相同的取代或未取代的单价烃基,和尤其优选甲基和苯基。并不限制组分(C)在25℃下的粘度,但优选为1-100000mPa.s,和更优选1-10000mPa.s。

在该组合物中,并不限制组分(C)的含量,只要它的含量足以固化该组合物即可,和以组分(A)中的每mol链烯基计,在该组合物中与硅键合的氢原子优选在0.1-10mol范围内,更优选在0.1-5mol范围内,甚至更优选在0.5-5mol范围内,和理想地在1-5mol范围内。这是因为当组分(C)的含量小于以上提及的范围的下限时,所得组合物倾向于固化不充分,和当含量超过以上提及的范围的上限时,所得固化产物的耐热性倾向于下降。

组分(D)是赋予组合物满意粘合性的粘合促进剂。组分(D)优选是每一分子具有至少一个键合到硅原子上的可水解基团的有机硅化合物,和更优选具有至少两个键合到同一硅原子上的可水解基团的有机硅化合物。该可水解基团可以是例如甲氧基、乙氧基、丙氧基、丁氧基、甲氧基-乙氧基,或其它这种烷氧基;乙酰氧基或其它这种酰氧基;异丙烯氧基或其它这种链烯氧基;或二甲基酮肟、甲基乙基酮肟或其它这种肟基,但可水解基团优选烷氧基,和更优选甲氧基。组分(D)优选是具有三甲氧基的有机硅化合物。在该有机硅化合物中,除了与前面所述的那些相同的取代或未取代的单价烃基以外,键合到硅原子上的除了可水解基团以外的基团的实例包括3-环氧丙氧丙基、4-环氧丙氧丁基和其它这种环氧丙氧烷基;2-(3,4-环氧基环己基)乙基、3-(3,4-环氧基环己基)丙基和其它这种环氧基环己基烷基;含有环氧基的单价有机基团,如4-oxyranyl丁基、8-oxyranyl辛基和其它这种oxyranyl烷基;3-甲基丙烯酰氧基丙基和含有丙烯酰基的其它这种单价有机基团;和氢原子。由于可对各种基体提供满意的粘合,该有机硅化合物优选每一分子具有至少一个含环氧基的单价有机基团。这种有机硅化合物的实例包括有机硅烷、有机硅氧烷和硅灭鼠。这种有机硅氧烷的分子结构的实例包括直链结构、部分支化的直链结构、支链结构、环结构和网状结构,和尤其优选直链结构、支链结构或网状结构。

在组分(D)中,有机硅化合物的实例包括3-环氧丙氧丙基三甲氧基硅烷、2-(3,4-环氧基环己基)乙基三甲氧基硅烷、3-甲基丙烯酰氧基丙基三甲氧基硅烷和其它这种有机硅烷;每一分子具有与硅键合的烷氧基和与硅键合的链烯基或与硅键合的氢原子中的每一种的至少一个的有机硅氧烷,每一分子具有至少一个与硅键合的烷氧基的有机硅烷或有机硅氧烷和每一分子具有与硅键合的羟基和与硅键合的链烯基中的每一种的至少一个的有机硅氧烷的混合物;如以下的平均单元式所示的有机硅氧烷:

其中a,b和c是正数,

如以下的平均单元式所示的有机硅氧烷:

其中a,b和c是正数,

如下式所示的硅灭鼠

如下式所示的硅灭鼠

在该组合物中,并不限制组分(D)的含量,只要它以能赋予组合物满意的粘合性的足够用量存在即可,但以每100重量份的组分(A)计,优选0.01-20重量份,和更优选0.1-10重量份。这是因为当组分(D)的含量小于以上提及的范围的下限时,所得组合物的粘合性倾向于下降,而当含量超过以上提及的范围的上限时,尽管所得组合物的粘合性保持不受影响,但所得固化产物的机械特征倾向于受到负面影响。

组分(E)是在组合物中促进固化反应的氢化硅烷化催化剂。组分(E)的实例包括铂催化剂、铑催化剂和钯催化剂,和尤其优选铂催化剂,因为它可显著促进固化反应。这种铂催化剂的实例包括铂的细粉、铂黑、承载铂的二氧化硅微粉、承载铂的活性炭、氯铂酸、氯铂酸的醇溶液、铂-烯烃络合物、铂链烯基硅氧烷络合物,和树脂粉末,其中这些铂催化剂分散或包封在丙烯酸树脂、聚碳酸酯树脂、硅氧烷树脂、聚酰胺树脂或其它这种热塑性树脂内。

在该组合物中,并不限制组分(E)的含量,只要它以足以促进以上提及的组合物的固化反应的用量存在即可;例如,当铂催化剂用作组分(E)时,在催化剂内的铂金属的含量相对于组合物优选0.01-1000ppm单位重量,和更优选0.1-500ppm。这是因为当组分(E)的含量小于以上提及的范围的下限时,所得组合物的固化反应倾向于极慢,而当含量超过以上提及的范围的上限时,尽管固化速度仍保持基本不受影响,但所得固化产物处于被着色或经历其它非所需变化的危险之中。

为了调节固化速度,以上提及的组合物优选含有固化抑制剂,如3-甲基-1-丁炔-3-醇、3,5-二甲基-1-己炔-3-醇、苯基丁炔醇,或另一这种炔醇;3-甲基-3-戊烯-1-炔、3,5-二甲基-3-己烯-1-炔、或另一这种烯-炔化合物;1,3,5,7-四甲基-1,3,5,7-四乙烯基环四硅氧烷、1,3,5,7-四甲基-1,3,5,7-四己烯基环四硅氧烷、或含有链烯基的另一这种有机硅氧烷;分子式CH3Si[OC(CH3)2C≡CH]3所示的有机硅烷、分子式CH3(CH2=CH)Si[OC(CH3)2C≡CH]2所示的有机硅烷、分子式(CH3)3Si[OC(CH3)2C≡CH]所示的有机硅烷或含有炔氧基的另一这种有机硅烷;或苯并三唑。

在该组合物中,并不限制固化抑制剂的含量,但以每100重量份组分(A)计,优选0.00001-5重量份。这是因为当固化抑制剂的含量小于以上提及的范围的下限时,所得组合物的固化速度难以调节和处理操作受到损害,而当含量超过以上提及的范围的上限时,所得组合物处于固化不充分的危险之中。

组合物也可含有染料、颜料、赋予耐热性的试剂、阻燃剂,和作为其它任选组分可共同混合到可固化硅氧烷组合物内的其它添加剂,只要不损害本发明的目的即可。

为了调节制备以上提及的片材用的任何可氢化硅烷化固化的硅氧烷组合物的固化速度,可例如选择组分(C)的类型,选择组分(E)的类型,调节其含量,选择固化抑制剂的类型和调节其含量。具体地,当在组合物中,在分子链的端位具有与硅键合的氢原子的有机聚硅氧烷用作组分(C)时,实现较高的反应性,所述较高反应性通过在分子链的侧链中具有与硅键合的氢原子的有机聚硅氧烷来提供,和因此所得组合物快速固化。另外,在该组合物中,采用较大含量的组分(E),所得组合物较快速地固化。另外,采用较大含量的固化抑制剂,所得组合物较慢地固化。因此,可制备具有不同固化速度的粘土状可固化硅氧烷组合物。这些粘土状可固化硅氧烷组合物的固化速度可以例如基于其90%硫化时间{tc(90)}来确定,所述90%硫化时间是根据JIS K6300的规定,使用振荡硫化测试仪进行的硫化试验中在相同的温度条件(例如130℃,150℃)下测量的。

在图1中,保护膜3和4牢固地粘接到片材的两个表面上。保护膜的采用是任选的,但保护膜优选牢固地粘接到片材的任一侧或两侧上,因为它们避免灰尘沉积在片材的正面上。当使用片材时,剥离掉保护膜。保护膜3和4可以相同或者不同。这种保护膜的实例具体地包括含聚对苯二甲酸乙二酯树脂(PET)、聚丙烯树脂(PP)、聚醚砜树脂(PES)、三乙酸纤维素树脂(TAC)和其它这种纤维素树脂以及聚酰亚胺树脂、聚酯树脂、聚醚树脂、环氧树脂、酚醛树脂、聚酰胺树脂和其它这种有机树脂的膜;和其中含这些有机树脂的膜的表面用氟烃树脂或另一有机树脂覆盖的膜。

并不限制制备片材的方法,和实例包括其中将在甲苯、庚烷或另一这种有机溶剂内的粘土状可固化硅氧烷组合物的溶液施加到保护膜上,将固化速度不同于前述组合物的粘土状可固化硅氧烷组合物的有机溶剂溶液类似地施加到另一膜上,和然后一起层压粘土状可固化硅氧烷组合物的方法;其中将粘土状可固化硅氧烷组合物的有机溶剂溶液施加到保护膜上,和进一步施加固化速度不同于前述组合物的粘土状可固化硅氧烷组合物的有机溶剂溶液的方法;和其中通过压延用组合物覆盖保护膜,然后施加固化速度不同于前述组合物的粘土状可固化硅氧烷组合物的有机溶剂溶液的方法。

图2示出了本发明另一可供替代的硅氧烷基粘合片材。该片材在一个表面上具有固化的硅氧烷层5和在另一表面上具有粘土状可固化的硅氧烷组合物层6。并不限制固化层5的厚度,但优选100微米或更低,更优选1-100微米,和甚至更优选1-50微米。也不限制组合物层6的厚度,但优选100微米或更低,更优选1-100微米,和甚至更优选1-50微米。也不限制片材的厚度,但优选100微米或更低。

例如通过固化可氢化硅烷化固化的硅氧烷组合物、可缩合固化的硅氧烷组合物、通过包括有机过氧化物的自由基反应可固化的硅氧烷组合物、通过高能辐射可固化的硅氧烷组合物,或另一可固化的硅氧烷组合物来形成固化层5,但优选通过固化可氢化硅烷化固化的硅氧烷组合物来形成固化层5。并不限制固化产物的性能,但优选具有弹性体的那些性能,和尤其优选具有橡胶的那些性能。

在该片材中,并不限制如JIS K 6249规定的粘土状可固化硅氧烷组合物的可塑值,但优选100-800,更优选100-700,和甚至更优选100-500。根据JIS K 6249的技术要求,这一可塑值是当通过平行板塑性计(William’s Plastimeter),施加49±0.05N的负载到样品{体积为2±0.02cm3的圆柱形物体(直径:16mm,高度:10mm)}上3分钟时的数值。

并不限制通过固化粘土状可固化硅氧烷组合物而获得的固化硅氧烷组合物的性能,但优选具有弹性体的那些性能,和尤其优选具有橡胶的那些性能。并不限制该可固化硅氧烷组合物的固化结构,和其实例包括可氢化硅烷化固化的硅氧烷组合物、可缩合固化的硅氧烷组合物、通过包括有机过氧化物的自由基反应可固化的硅氧烷组合物,和通过高能辐射可固化的硅氧烷组合物,其中尤其优选可氢化硅烷化固化的硅氧烷组合物。可氢化硅烷化固化的硅氧烷组合物如前所述。

在图2中,保护膜7和8牢固地粘接到硅氧烷基粘合片材的两个表面上。这些保护膜的采用是任选的,但保护膜优选牢固地粘接到片材的任一侧或两侧上,因为它们避免灰尘沉积在片材的正面上。当使用片材时,剥离掉保护膜。保护膜7和8可以相同或者不同。这种保护膜的实例包括与前述相同的膜。

并不限制制备片材的方法,和实例包括其中将在甲苯、庚烷或另一这种有机溶剂内的粘土状可固化硅氧烷组合物的溶液施加到保护膜上,将固化速度不同于前述组合物的粘土状可固化硅氧烷组合物的有机溶剂溶液类似地施加到另一膜上,和然后一起层压粘土状可固化硅氧烷组合物,和仅仅固化粘土状可固化硅氧烷组合物中的一层的方法;其中将粘土状可固化硅氧烷组合物的有机溶剂溶液施加到保护膜上和固化该组合物,然后施加粘土状可固化硅氧烷组合物的有机溶剂溶液到固化产物上的方法;其中施加液体可固化硅氧烷组合物到保护膜上,固化该组合物,然后将在甲苯、庚烷或另一这种有机溶剂内的粘土状可固化硅氧烷组合物的溶液施加到另一保护膜上,和一起层压这些膜的方法;其中将组分(C)或组分(E)施加到保护膜上,将粘土状可固化硅氧烷组合物的有机溶剂溶液类似地施加到另一保护膜上,将组分(C)或组分(E)与粘土状可固化硅氧烷组合物一起层压,然后仅仅固化粘土状可固化硅氧烷组合物的一个表面的方法;和其中通过压延用可固化硅氧烷组合物覆盖保护膜,然后施加粘土状可固化硅氧烷组合物的有机溶剂溶液到固化产物上的方法。

本发明的这种硅氧烷基粘合片材适于用作所有类型基体的粘合片材,因为它可满意地粘接光滑基体和在表面上具有不规则度的基体,和可使粘接层的厚度几乎变均匀。特别地,使用本发明的硅氧烷基粘合片材作为芯片连接元件和在至少一个表面上具有不规则度的半导体芯片的粘合剂是有利的,因为可使粘接层的厚度变得几乎均匀,因此在随后的布线粘接工艺过程中不会产生不便。本发明的这种硅氧烷基粘合片材适合作为粘合剂,用于把在至少一个表面上具有不规则度的半导体芯片粘接到芯片连接元件上。片材优选具有低含量的铀和钍。片材还优选具有低含量的钠、钾和其它这种碱金属离子或卤素离子。此外,片材优选具有低含量的低分子硅氧烷。

粘接半导体芯片和芯片连接元件的方法

图3示出了粘接本发明半导体芯片和芯片连接元件的方法。该方法包括步骤:

(1)通过将层压体切割成小片,生产半导体芯片,其中所述层压体由粘接到晶片9上的固化硅氧烷层10、牢固地粘接到固化层10上的粘土状可固化硅氧烷组合物层11、牢固地粘接到组合物层11上的保护膜12,和用粘合剂连接到膜12上的片材13组成;

(2)从芯片中剥离保护膜12和片材13;

(3)通过借助组合物层11压制半导体芯片到芯片连接元件上,将半导体芯片粘接到芯片连接元件上;和

(4)固化该组合物层11。

形成层压体(所述层压体包括粘接到晶片9上的固化的硅氧烷层10和牢固地粘接到固化层10上的粘土状可固化硅氧烷组合物层11)的方法的实例包括,在层压体内固化组合物(I)的层,以便防止组合物(II)的层固化的方法,其中所述层压体包括牢固地粘接到晶片上的粘土状可固化硅氧烷组合物(I)的层和牢固地粘接到组合物(I)上且赋予低于组合物(I)的层固化速度的粘土状可固化硅氧烷组合物(II)的层;和其中将固化硅氧烷物质的固化产物层粘接到晶片上,以便防止粘土状可固化硅氧烷组合物固化的方法,所述固化产物层通过层压固化的硅氧烷物质层和牢固地粘接到晶片上的固化产物上的粘土状可固化硅氧烷组合物层而形成。这些方法中使用的硅氧烷基粘合片材如前所述。

接下来,将粘合片材13层压到保护膜12上并从晶片9侧处切割成小片。然后可切割粘合片材13到几乎中间处。可通过从如此获得的半导体芯片中剥离掉保护膜12和粘合片材13,借助粘土状可固化硅氧烷组合物层11,在压力下将芯片粘接到半导体芯片连接元件上,然后固化组合物层11,从而粘接半导体芯片和芯片连接元件。并不特别限制粘接条件,但优选例如加热到50-250℃,和更优选加热到100-150℃。压制粘接时间优选1秒-2小时。并不特别限制压力,只要半导体芯片或芯片连接元件不被损坏即可,但优选在0.3-2.0MPa范围内。

半导体器件

在本发明的半导体器件中,通过以上提及的硅氧烷基粘合片材,将半导体芯片粘接到芯片连接元件上,和半导体器件的实例包括二极管、晶体管、半导体开关元件、单片集成电路(IC)、混合IC、大规模集成电路(LSI)和非常大规模集成电路(VLSI),和称为芯片规模封装件(CSP)的封装件也包括在本发明的半导体器件内。半导体芯片的实例包括二极管、晶体管、半导体开关元件、单片IC和半导体芯片与这种半导体芯片安装在其上的电路板元件,如混合IC、LSI和VLSI。

半导体芯片连接元件的实例包括陶瓷、玻璃、环氧树脂、聚酰亚胺树脂、酚醛树脂、Bakelite树脂、三聚氰胺树脂、玻璃纤维增强的环氧树脂、玻璃纤维增强的BT树脂和其它这种电路板以及芯片载体与接头。粘接线的实例包括金、银、铝和其它这种金属薄线。超声热压缩粘接常用作连接粘接线的方法。

半导体器件的实例包括含硅氧烷基粘合片材的半导体器件,所述硅氧烷基粘合片材在一侧上具有粘土状可固化硅氧烷组合物(I)的层,和在另一侧上具有固化速度慢于组合物(I)的层的粘土状可固化硅氧烷组合物(II)的层,从而当半导体芯片粘接到芯片连接元件上时,(i)组合物(I)的层如此固化,以便在组合物(I)的层保持与半导体芯片接触的同时,组合物(II)的层仍然未固化,和随后在组合物(II)的层保持与半导体芯片连接元件接触的同时组合物(II)的层固化,或从而(ii)组合物(I)的层如此固化,以便在组合物(I)的层保持与半导体芯片连接元件接触的同时组合物(II)的层仍然未固化,和随后在组合物(II)的层保持与半导体芯片接触的同时,组合物(II)的层固化的半导体器件。

并不特别限制将硅氧烷基粘合片材粘接到半导体芯片或者芯片连接元件上的条件,但例如优选在50-250℃下,和更优选在100-150℃下进行加热。压制粘接时间优选1秒-2小时。并不特别限制压力,只要半导体芯片或芯片连接元件没有受到损坏即可,但优选0.3-2.0MPa。

在根据上述(i)的半导体器件中,将粘土状可固化硅氧烷组合物(I)的层粘接到半导体芯片上,和半导体芯片的表面可以或者光滑或者不规则。在以上提及的粘接条件下,必须在其中粘土状可固化硅氧烷组合物(II)的层不固化的条件下使固化产物层(I)固化。粘土状可固化硅氧烷组合物(II)的层然后粘接到半导体芯片连接元件上,和连接元件的表面可以或者光滑或者不规则。接下来,可通过在以上提及的粘接条件下固化,从而粘接组合物(II)的层。

在根据上述(ii)的半导体器件中,将粘土状可固化硅氧烷组合物(I)的层粘接到半导体芯片连接元件上,和芯片连接元件的表面可以或者光滑或者不规则。在以上提及的粘接条件下,必须在其中粘土状可固化硅氧烷组合物(II)的层不固化的条件下使固化产物层(I)固化。粘土状可固化硅氧烷组合物(II)的层然后粘接到半导体芯片连接元件上,和连接元件的表面可以或者光滑或者不规则。接下来,可通过在以上提及的粘接条件下固化,从而粘接组合物(II)的层。

其中在一侧上具有固化硅氧烷层和在另一侧上具有粘土状可固化硅氧烷组合物层的硅氧烷基粘合片材被用于粘接半导体芯片到芯片连接元件上的这种半导体器件的实例包括:(iii)其中如此粘接固化层,以便在固化层保持与半导体芯片接触的同时组合物层仍然未固化,和随后在组合物层保持与半导体芯片连接元件接触的同时固化组合物层的半导体器件,或者(iv)其中如此粘接固化层,以便在固化层保持与半导体芯片连接元件接触的同时组合物层仍然未固化,和随后在组合物层保持与半导体芯片接触的同时固化组合物层的半导体器件。

并不特别限制将硅氧烷基粘合片材粘接到半导体芯片或者芯片连接元件上的条件,但例如优选在50-250℃下加热,和更优选在100-150℃下加热。压制粘按时间优选1秒-2小时。并不特别限制压力,只要半导体芯片或芯片连接元件没有受到损坏即可,但优选在0.3-2.0MPa范围内。

特别地,在以上提及的(iii)半导体器件中,半导体芯片必须具有光滑的表面,因为硅氧烷固化层被粘接到半导体芯片上,和在以上提及的粘接条件下,必须在其中粘土状可固化硅氧烷组合物层不固化的条件下粘接固化层。然后将粘土状可固化硅氧烷组合物层粘接到半导体芯片连接元件上,和芯片连接元件的表面优选具有不规则度。接下来,通过在以上提及的粘接条件下固化,从而粘接组合物。

在以上提及的(iv)半导体器件中,芯片连接元件必须具有光滑的表面,因为硅氧烷固化层被粘接到半导体芯片连接元件上,和在以上提及的粘接条件下,必须在其中粘土状可固化硅氧烷组合物层不固化的条件下粘接固化层。然后将粘土状可固化硅氧烷组合物层粘接到半导体芯片上,和芯片的表面优选具有不规则度。接下来,通过在以上提及的粘接条件下固化,从而粘接组合物。

实施例

在实施例中,粘度是在25℃下的数值。粘土状可固化硅氧烷组合物的可塑值是根据JIS K 6249的技术要求,通过平行板塑性计(William’s Plastimeter),施加49±0.05N的负载到样品{体积为2±0.02cm3的圆柱形物体(直径:16mm,高度:10mm)}上3分钟时的数值。粘土状可固化硅氧烷组合物的固化速度基于其90%硫化时间{tc(90)}来表示,所述90%硫化时间是根据JIS K 6300的规定,使用振荡硫化测试仪进行的硫化试验中在相同的温度条件(例如130℃,150℃)下测量的。此外,根据JIS K 6253的规定,通过A型硬度计测量固化硅氧烷物质的硬度。

参考实施例1-粘土状硅橡胶组合物I的制备

采用捏合机,通过加热并混合100重量份(重均分子量=370000)分子链的两端用二甲基乙烯基甲硅烷氧基封端的二甲基硅氧烷/甲基乙烯基硅氧烷共聚物生橡胶(它包括99.85mol%二甲基硅氧烷单元和0.15mol%甲基乙烯基硅氧烷单元)、10.0重量份粘度为60mPa.s的分子链的两端用硅烷醇基封端的二甲基硅氧烷低聚物,和40重量份热解法二氧化硅(AEROSIL 200,由Japan Aerosil,Co.,Ltd.制造;BET比表面积200m2/g),来生产硅橡胶基质。

接下来,使用两辊磨机,均匀混合100重量份所述硅橡胶基质,0.8重量份粘度为30mPa.s的分子链的两端用三甲基甲硅烷氧基封端的甲基氢化聚硅氧烷(在甲基氢化聚硅氧烷内与硅键合的氢原子含量为3.1mol/mol在分子链的两端用二甲基乙烯基甲硅烷氧基封端且包含在以上提及的硅橡胶基质内的二甲基硅氧烷/甲基乙烯基硅氧烷共聚物生橡胶内的乙烯基)、0.05重量份式CH3Si[OC(CH3)2C≡CH]3所示的有机硅烷作为固化抑制剂,和1.0重量份由下述平均单元式所示的有机硅氧烷作为粘合促进剂;

然后混合铂的1,3-二乙烯基四甲基二硅氧烷络合物的1,3-二乙烯基四甲基二硅氧烷溶液(在本发明的组合物中,在络合物内的金属铂含量为20ppm重量单位),生产粘土状硅橡胶组合物(I)。

该粘土状可固化硅氧烷组合物(I)的可塑值为240。根据JIS K 6300的规定,该粘土状可固化硅氧烷组合物(I)的固化速度tc(90)在130℃下为2.5分钟,和在150℃下为1分钟。通过固化获得的硅橡胶的硬度为60。

接下来,在分开的烧瓶内搅拌20重量份该粘土状硅橡胶组合物(I)和80重量份甲苯,产生粘度为3500mPa.s的粘土状硅橡胶组合物(I)的甲苯溶液。

参考实施例2-粘土状硅橡胶组合物II的制备

采用捏合机,通过加热并混合100重量份(重均分子量=370000)分子链的两端用二甲基乙烯基甲硅烷氧基封端的二甲基硅氧烷/甲基乙烯基硅氧烷共聚物生橡胶(它包含99.85mol%二甲基硅氧烷单元和0.15mol%甲基乙烯基硅氧烷单元)、10.0重量份粘度为60mPa.s的分子链的两端用硅烷醇基封端的二甲基硅氧烷低聚物,和40重量份热解法二氧化硅(AEROSIL 200,由Japan Aerosil,Co.,Ltd.制造;BET比表面积200m2/g),来生产硅橡胶基质。

接下来,使用两辊磨机,均匀混合100重量份以上提及的硅橡胶基质,0.8重量份粘度为30mPa.s的分子链的两端用三甲基甲硅烷氧基封端的甲基氢化聚硅氧烷(在该甲基氢化聚硅氧烷内与硅键合的氢原子含量为3.1mol/mol在分子链的两端用二甲基乙烯基甲硅烷氧基封端且包含在以上提及的硅橡胶基质内的二甲基硅氧烷/甲基乙烯基硅氧烷共聚物生橡胶内的乙烯基)、0.2重量份分子式CH3Si[OC(CH3)2C≡CH]3所示的有机硅烷作为固化抑制剂,和1.0重量份由下述平均单元式所示的有机硅氧烷作为粘合促进剂;

然后混合铂的1,3-二乙烯基四甲基二硅氧烷络合物的1,3-二乙烯基四甲基二硅氧烷溶液(在本发明的组合物中,在络合物内的金属铂含量为20ppm重量单位),生产粘土状硅橡胶组合物(II)。

粘土状硅橡胶组合物(II)的可塑值为240。根据JIS K 6300的规定,粘土状硅橡胶组合物(II)的固化速度tc(90)在130℃下为40分钟,和在150℃下为10分钟。通过固化获得的硅橡胶的硬度为60。

接下来,在分开的烧瓶内搅拌20重量份以上提及的粘土状硅橡胶组合物(II)和80重量份甲苯,产生粘度为3500mPa.s的粘土状硅橡胶组合物(II)的甲苯溶液。

参考实施例3-粘土状硅橡胶组合物III的制备

采用捏合机,通过加热并混合100重量份(重均分子量=370000)分子链的两端用二甲基乙烯基甲硅烷氧基封端的二甲基硅氧烷/甲基乙烯基硅氧烷共聚物生橡胶(它包含99.85mol%二甲基硅氧烷单元和0.15mol%甲基乙烯基硅氧烷单元)、10.0重量份粘度为60mPa.s的分子链的两端用硅烷醇基封端的二甲基硅氧烷低聚物,和40重量份热解法二氧化硅(AEROSIL 200,由Japan Aerosil,Co.,Ltd.制造;BET比表面积200m2/g),来生产硅橡胶基质。

接下来,使用两辊磨机;均匀混合100重量份该硅橡胶基质,0.8重量份粘度为30mPa.s的分子链的两端用三甲基甲硅烷氧基封端的甲基氢化聚硅氧烷(在甲基氢化聚硅氧烷内与硅键合的氢原子含量为3.1mol/mol在分子链的两端用二甲基乙烯基甲硅烷氧基封端且包含在以上提及的硅橡胶基质内的二甲基硅氧烷/甲基乙烯基硅氧烷共聚物生橡胶内的乙烯基)、0.2重量份分子式CH3Si[OC(CH3)2C≡CH]3所示的有机硅烷作为固化抑制剂,和1.0重量份由下述平均单元式所示的有机硅氧烷作为粘合促进剂;

然后混合铂的1,3-二乙烯基四甲基二硅氧烷络合物的1,3-二乙烯基四甲基二硅氧烷溶液(在本发明的组合物中,在络合物内的金属铂含量为20ppm重量单位),来生产粘土状硅橡胶组合物(II)。

该粘土状硅橡胶组合物(III)的可塑值为240。根据JIS K 6300的规定,该粘土状硅橡胶组合物(III)的固化速度tc(90)在130℃下为40分钟,和在150℃下为10分钟。通过固化获得的硅橡胶的硬度为60。

接下来,在分开的烧瓶内搅拌20重量份以上提及的粘土状硅橡胶组合物(III)和80重量份甲苯,产生粘度为3500mPa.s的粘土状硅橡胶组合物(III)的甲苯溶液。

实施例1

通过使用刮刀,将厚度为25微米的参考实施例2中生产的粘土状硅橡胶组合物(II)的甲苯溶液施加到聚酯砜树脂膜上,然后在室温下吹干2小时,和通过在150℃下加热所得物30分钟来固化粘土状硅氧烷橡胶组合物(II),从而生产牢固地粘接到聚酯砜树脂膜上的厚度为5微米的硅橡胶片材。

接下来,使用刮刀,将厚度为225微米的参考实施例2中生产的粘土状硅橡胶组合物(II)的甲苯溶液施加到硅橡胶片材上,并在室温下吹干所得产物2小时。吹干的硅橡胶片材和粘土状硅橡胶组合物层的总厚度为50微米。接下来,通过橡胶辊,将聚酯砜树脂膜牢固地粘接到粘土状硅橡胶组合物层的表面上,和层压图2所示的硅橡胶层与粘土状硅橡胶组合物层,生产其中作为保护膜的聚酯砜树脂膜牢固地粘接到其两个表面上的硅氧烷基粘合片材。

将硅氧烷基粘合片材在一侧切割成10mm的正方形,剥离掉牢固地粘接到硅橡胶层上的聚酯砜树脂膜,在190℃和1.0MPa的压制下压制粘接在一侧的10mm的硅芯片1秒钟,剥离掉牢固地粘接到粘土状硅橡胶组合物层上的聚酯砜树脂膜,在190℃和1.0MPa的压制下压制粘接该层到不规则度为20微米、由玻璃纤维增强的环氧树脂制造的板的布线表面上经1秒钟,和在150℃下加热所得物60分钟,使粘土状硅橡胶组合物固化,从而生产器件。

测量该器件的总厚度,和通过减去硅芯片和由玻璃纤维增强的环氧树脂制造的板的厚度,测量在芯片的四个角处硅氧烷粘合层的厚度,于是发现在所有情况下,硅氧烷粘合层的厚度均匀为48微米。向上牵拉硅芯片,以证实粘合性,和发现硅氧烷粘合层经历内聚破坏,从而证实粘合性令人满意。

接下来,通过超声热压缩粘接,将直径为30微米的金属线粘接到以上提及的器件上,产生图4所示的半导体器件。使30个这些半导体器件在-50℃下静置30分钟,然后立即进行热循环试验,其中在150℃下静置30分钟为1次循环,和评价以上提及的器件的缺陷导电分数(conductive fraction defective)。结果见表1。

实施例2

使用刮刀,将参考实施例1生产的粘土状硅橡胶组合物(I)的甲苯溶液以50微米的厚度施加到不同于以上提及的聚酯砜树脂膜上,和在室温下吹干2小时。在干燥之后,粘土状硅橡胶组合物(I)的层的厚度为5微米。

使用刮刀,将参考实施例2生产的粘土状硅橡胶组合物(II)的甲苯溶液以225微米的厚度施加到不同于以上提及的聚酯砜树脂膜上,和在室温下吹干2小时。在干燥之后,粘土状硅橡胶组合物(II)的层的厚度为45微米。

接下来,一起层压粘土状硅橡胶组合物(I)的层和粘土状硅橡胶组合物(II)的层,生产图1所示的硅氧烷基粘合片材,它包括聚酯砜树脂膜粘接到其两个表面上的两层粘土状硅橡胶组合物。

将硅氧烷基粘合片材在一侧切割成10mm的正方形,剥离掉牢固地粘接到粘土状硅橡胶组合物(I)的层上的聚酯砜树脂膜,通过在150℃和1.0MPa的压力下压制粘接在一侧的10mm的硅氧烷芯片2分钟,来固化粘土状硅橡胶组合物(I)的层,然后剥离掉牢固地粘接到粘土状硅橡胶组合物(II)的层上的聚酯砜树脂膜,在190℃和1.0MPa的压力下压制粘接该层到不规则度为20微米、由玻璃纤维增强的环氧树脂制造的板的布线表面上经1秒,和在150℃下加热所得物60分钟,以使粘土状硅橡胶组合物固化,从而生产器件。

测量该器件的总厚度,和通过减去芯片和由玻璃纤维增强的环氧树脂制造的板的厚度,测量在芯片的四个角处硅氧烷粘合层的厚度,于是发现在所有情况下,硅氧烷粘合层的厚度均匀为48微米。向上牵拉硅氧烷芯片,以证实粘合性,和发现硅氧烷粘合层经历内聚破坏,从而证实粘合性令人满意。

接下来,通过超声热压缩粘接,将直径为30微米的金属线粘接到以上提及的器件上,产生图4所示的半导体器件。使30个这些半导体器件在-50℃下静置30分钟,然后立即进行热循环试验,其中在150℃下静置30分钟为1次循环,和评价以上提及的器件的缺陷导电分数。结果见表1。

实施例3

通过在130℃下加热实施例2中生产的硅氧烷基粘合片材10分钟,来固化仅仅粘土状硅橡胶组合物(I)的层,从而产生图2所示的硅氧烷基粘合片材,其中层压硅橡胶层和粘土状硅橡胶组合物(II)的层,并将聚酯砜树脂膜作为保护膜牢固地粘接到两个表面上。

将硅氧烷基粘合片材在一侧切割成10mm的正方形,剥离掉牢固地粘接到硅橡胶层上的聚酯砜树脂膜,通过在190℃和1.0MPa的压力下压料粘接在一侧的10mm的硅氧烷芯片1秒,然后剥离掉牢固地粘接到粘土状硅橡胶组合物(II)的层上的聚酯砜树脂膜,在190℃和1.0MPa的压力下压制粘接该层到不规则度为20微米、由玻璃纤维增强的环氧树脂制造的板的布线表面上经1秒,和在150℃下加热所得物60分钟,使粘土状硅橡胶组合物(II)的层固化,从而生产器件。

测量该器件的总厚度,和通过减去芯片和由玻璃纤维增强的环氧树脂制造的板的厚度,测量在芯片的四个角处硅氧烷粘合层的厚度,于是发现在所有情况下,硅氧烷粘合层的厚度均匀为48微米。向上牵拉硅氧烷芯片,以证实粘合性,和发现硅氧烷粘合层经历内聚破坏,从而证实粘合性令人满意。

接下来,通过超声热压缩粘接,将直径为30微米的金属线粘接到以上提及的器件上,产生图4所示的半导体器件。使30个这些半导体器件在-50℃下静置30分钟,然后立即进行热循环试验,其中在150℃下静置30分钟为1次循环,和评价以上提及的器件的缺陷导电分数。结果见表1。

实施例4

使用纱网,在厚度为50微米的聚酯砜树脂膜上涂布铂的1,3-二乙烯基四甲基二硅氧烷络合物的甲苯溶液(其中以金属铂的重量单位计,含量为500ppm),和在室温下使所得物静置2小时并吹干。

使用刮刀,将参考实施例2生产的粘土状硅橡胶组合物(II)的甲苯溶液以250微米的厚度施加到聚酯砜树脂膜上,和在室温下吹干所得物2小时。在干燥之后,粘土状硅橡胶组合物(II)的层的厚度为50微米。

接下来,一起层压粘土状硅橡胶组合物(II)的层和涂布有铂的1,3-二乙烯基四甲基二硅氧烷络合物的表面,产生聚酯砜树脂膜牢固地粘接到其两个表面上的含粘土状硅橡胶组合物的粘土状硅氧烷基粘合片材,然后通过在130℃下加热所得物10分钟,仅仅固化与铂的1,3-二乙烯基四甲基二硅氧烷络合物接触的粘土状硅橡胶组合物(II)的层的表面,和层压硅橡胶层与粘土状硅橡胶组合物层,产生其中聚酯砜树脂膜作为保护膜牢固地粘接到两个表面上的粘土状硅氧烷基粘合片材。在粘土状层一侧,硅氧烷层维持约30微米的厚度。

将粘土状硅氧烷基粘合片材在一侧切割成10mm的正方形,剥离掉牢固地粘接到硅橡胶层上的聚酯砜树脂膜,通过在190℃和1.0MPa的压力下压制粘接在一侧的10mm的硅氧烷芯片1秒,然后剥离掉牢固地粘接到粘土状硅橡胶组合物(II)的层上的聚酯砜树脂膜,在190℃和1.0MPa的压力下压制粘接该层到不规则度为20微米、由玻璃纤维增强的环氧树脂制造的板的布线表面上经1秒,和在150℃下加热所得物60分钟,使粘土状硅橡胶组合物(II)的层固化,从而生产器件。

测量该器件的总厚度,和通过减去芯片和由玻璃纤维增强的环氧树脂制造的板的厚度,测量在芯片的四个角处硅氧烷粘合层的厚度,于是发现在所有情况下,硅氧烷粘合层的厚度均匀为48微米。向上牵拉硅氧烷芯片,以证实粘合性,和发现硅氧烷粘合层经历内聚破坏,从而证实粘合性令人满意。

接下来,通过超声热压缩粘接,将直径为30微米的金属线粘接到以上提及的器件上,产生半导体器件。使30个这些半导体器件在-50℃下静置30分钟,然后立即进行热循环试验,其中在150℃下静置30分钟为1次循环,和评价以上提及的器件的缺陷导电分数。结果见表1。

实施例5

使用纱网,在厚度为50微米的聚酯砜树脂膜上涂布平均单元分子式[(CH3)2HSiO1/2]0.6(SiO2)0.4所示的有机聚硅氧烷(与硅键合的氢原子含量=0.97wt%)的甲苯溶液(固体10wt%),和在室温下使所得物静置2小时并吹干。

使用刮刀,将参考实施例2生产的粘土状硅橡胶组合物(II)的甲苯溶液以250微米的厚度施加到聚酯砜树脂膜上,和在室温下吹干所得产物2小时。在干燥之后,粘土状硅橡胶组合物(II)的层的厚度为50微米。

接下来,一起层压粘土状硅橡胶组合物(II)的层和涂布有平均单元分子式[(CH3)2HSiO1/2]0.6(SiO2)0.4所示的有机聚硅氧烷的表面,产生聚酯砜树脂膜在两侧牢固地粘接到其上的含粘土状硅橡胶组合物的硅氧烷基粘合片材,然后通过在130℃下加热所得物10分钟,仅仅固化与平均单元分子式[(CH3)2HSiO1/2]0.6(SiO2)0.4所示的有机聚硅氧烷接触的粘土状硅橡胶组合物(II)的层的表面,和如图2所示,层压硅橡胶层与粘土状硅橡胶组合物层,产生其中聚酯砜树脂膜作为保护膜牢固地粘接到其两个表面上的粘土状硅氧烷基粘合片材。在粘土状层一侧,硅氧烷层维持约30微米的厚度。

将粘土状硅氧烷基粘合片材在一侧切割成10mm的正方形,剥离掉牢固地粘接到硅橡胶层上的聚酯砜树脂膜,通过在190℃和1.0MPa的压力下压制粘接在一侧的10mm的硅氧烷芯片1秒,然后剥离掉牢固地粘接到粘土状硅橡胶组合物(II)的层上的聚酯砜树脂膜,在190℃和1.0MPa的压力下压制粘接该层到不规则度为20微米、由玻璃纤维增强的环氧树脂制造的板的布线表面上经1秒,和在150℃下加热所得物60分钟,使粘土状硅橡胶组合物(II)的层固化,从而生产器件。

测量该器件的总厚度,和通过减去芯片和由玻璃纤维增强的环氧树脂制造的板的厚度,测量在芯片的四个角处硅氧烷粘合层的厚度,于是发现在所有情况下,硅氧烷粘合层的厚度均匀为48微米。向上牵拉硅氧烷芯片,以证实粘合性,和发现硅氧烷粘合层经历内聚破坏,从而证实粘合性令人满意。

接下来,通过超声热压缩粘接,将直径为30微米的金属线粘接到以上提及的器件上,产生半导体器件。使30个这些半导体器件在-50℃下静置30分钟,然后立即进行热循环试验,其中在150℃下静置30分钟为1次循环,和评价以上提及的器件的缺陷导电分数。结果见表1。

实施例6

剥离硅氧烷基粘合片材(其中粘土状硅橡胶组合物层(I)和粘土状硅橡胶组合物(II)的层层压在一起,且保护层紧密粘接到两个表面上)的在粘土状硅橡胶组合物(I)的层上的保护膜(在实施例2中生产),并在切割成小片之前使用橡胶辊牢固地将其粘接到4英寸的硅晶片上。接下来,在130℃下加热所得物10分钟,和固化仅仅粘土状硅橡胶组合物(I)的层。

接下来,将厚度为90微米的粘合片材层压到牢固地粘接到硅氧烷基粘合片材的保护膜上,而所述硅氧烷基粘合片材本身被粘接到硅晶片上,和使用由Disco Corporation制造的切割锯DAD 340,将该产品在一侧切割成10mm正方形。切掉粘合片材的底表面,从而留下60微米。

当使用粘合片材粘着切割的半导体芯片时,保护膜保持在粘合片材侧上。通过其中在室温下,在1.0MPa的压力下,将粘接到半导体芯片上的硅氧烷基粘合片材经1秒压制粘接到不规则度为20微米、由玻璃纤维增强的环氧树脂制造的板的布线表面上,和在150℃下加热所得物60分钟,使粘土状硅橡胶组合物层固化的方法,从而生产器件。

测量该器件的总厚度,和通过减去芯片和由玻璃纤维增强的环氧树脂制造的板的厚度,测量在芯片的四个角处硅氧烷粘合层的厚度,于是发现在所有情况下,硅氧烷粘合层的厚度均匀为48微米。向上牵拉硅氧烷芯片,以证实粘合性,和发现硅氧烷粘合层经历内聚破坏,从而证实粘合性令人满意。

接下来,通过超声热压缩粘接,将直径为30微米的金属线粘接到以上提及的器件上,产生图4所示的半导体器件。使30个这些半导体器件在-50℃下静置30分钟,然后立即进行热循环试验,其中在150℃下静置30分钟为1次循环,和评价以上提及的器件的缺陷导电分数。结果见表1。

对比例1

在室温下,通过Ross混合机,混合72重量份粘度为40000mPa.s的分子链的两端用二甲基乙烯基甲硅烷氧基封端的二甲基聚硅氧烷(乙烯基含量=0.08wt%)、15重量份粘度为6000mPa.s的分子链的两端用二甲基乙烯基甲硅烷氧基封端的二甲基硅氧烷/甲基乙烯基硅氧烷共聚物(乙烯基含量=0.84wt%)、1.5重量份水、3重量份六甲基二硅氮烷和10重量份热解法二氧化硅(AEROSIL 200,由JapanAerosil,Co.,Ltd.制造;BET比表面积200m2/g)1小时,然后在170℃下减压加热并混合2小时。将所得产物冷却到室温,产生半透明的糊状硅橡胶基质。

接下来,均匀混合100重量份以上提及的硅橡胶基质、3重量份粘度为5mPa.s的分子链的两端用三甲基甲硅烷氧基封端的二甲基硅氧烷/甲基氢化硅氧烷共聚物(与硅键合的氢原子的含量=0.7wt%)(在分子链的两端用三甲基甲硅烷氧基封端的二甲基硅氧烷/甲基氢化硅氧烷共聚物内与硅键合的氢原子含量为3.0mol/mol在分子链的两端用二甲基乙烯基甲硅烷基封端的二甲基聚硅氧烷内和在分子链的两端用二甲基乙烯基甲硅烷氧基封端的二甲基硅氧烷/甲基乙烯基硅氧烷共聚物内且包含在以上提及的硅橡胶基质内的乙烯基)、0.01重量份3-苯基-1-丁炔-3-醇作为固化抑制剂和1.0重量份下述平均单元式所示的有机聚硅氧烷作为粘合促进剂;

然后,混合铂的1,3-二乙烯基四甲基二硅氧烷络合物的1,3-二乙烯基四甲基二硅氧烷溶液(在本发明的组合物中,在络合物内的金属铂含量为5ppm重量单位),生产粘度为70000mPa.s的硅橡胶组合物(IV)。

将硅橡胶组合物夹在厚度为50微米的聚酯砜树脂膜之间,然后在对流烘箱内,在80℃下加热30分钟固化,同时通过具有调节透明度的两个不锈钢辊保持以上提及的硅橡胶组合物的厚度在50微米处,从而得到硅氧烷基粘合片材。

将硅氧烷基粘合片材在一侧切割成10mm的正方形,剥离掉一片聚酯砜树脂膜,在190℃和1.0MPa的压力下压制粘接在一侧的10mm的硅氧烷芯片1秒,然后剥离掉在相对侧上的聚酯砜树脂膜,在190℃和1.0MPa的压力下压制粘接该层到不规则度为20微米、由玻璃纤维增强的环氧树脂制造的板的布线表面上经1秒,和在150℃下加热所得物60分钟,生产器件。在该器件中,向上牵拉硅氧烷芯片以证实粘合性的结果是,硅氧烷粘合层的表面和由玻璃纤维增强的环氧树脂制造的板的布线表面剥离。因此,不可能将布线粘接施加到以上提及的器件上。

实施例7

通过使用刮刀,将厚度为25微米的参考实施例3生产的粘土状硅橡胶组合物(III)的甲苯溶液施加到聚酯砜树脂膜上,在室温下吹干所得物2小时,和通过在150℃下加热30分钟,固化粘土状硅橡胶组合物(III),来生产牢固地粘接到聚酯砜树脂膜上的厚度为5微米的硅橡胶片材。

接下来,使用刮刀,将厚度为225微米的参考实施例3中生产的粘土状硅橡胶组合物(III)的甲苯溶液施加到硅橡胶片材上,并在室温下吹干所得物2小时。吹干的硅橡胶片材和粘土状硅橡胶组合物层的总厚度为50微米。接下来,通过橡胶辊,将聚酯砜树脂膜牢固地粘接到粘土状硅橡胶组合物层的表面上,和层压图2所示的硅橡胶层与粘土状硅橡胶组合物层,生产其中作为保护膜膜的聚酯砜树脂膜牢固地粘接到两个表面上的硅氧烷基粘合片材(L)。

同时,采用Ross混合机,通过混合31重量份粘度为2200mPa.s的分子链的两端用二甲基乙烯基甲硅烷氧基封端的二甲基聚硅氧烷(乙烯基含量=0.23wt%;在200℃下蒸气压≥10mmHg的低分子量硅氧烷的含量=0.01wt%)、56重量份粘度为7000mPa.s的有机聚硅氧烷混合物(它由65wt%粘度为2000mPa.s的分子链的两端用二甲基乙烯基甲硅烷氧基封端的二甲基聚硅氧烷(乙烯基含量=0.23wt%)和35wt%由(CH2=CH)(CH3)2SiO1/2单元和SiO2单元组成的有机聚硅氧烷树脂(乙烯基含量=2.5wt%)组成)、和13重量份热解法二氧化硅(AEROSIL 200,由Japan Aerosil,Co.,Ltd.制造;BET比表面积200m2/g),然后在170℃下,在减压下加热并混合2小时,生产硅橡胶基质。冷却所得产物到室温,生产半透明的糊状硅橡胶基质。

接下来,均匀混合100重量份100重量份以上提及的硅橡胶基质、6重量份粘度为5mPa.s的在分子链的两端用三甲基甲硅烷氧基封端的二甲基硅氧烷/甲基氢化硅氧烷共聚物(与键合的氢原子的含量=0.7wt%)(在分子链的两端用三甲基甲硅烷氧基封端的二甲基硅氧烷/甲基氢化硅氧烷共聚物内与硅键合的氢原子含量为1.8mol/mol在分子链的两端用二甲基乙烯基甲硅烷基封端的二甲基聚硅氧烷内和在有机聚硅氧烷混合物内且包含在以上提及的硅橡胶基质内的乙烯基)、1.0重量份下述平均单元式所示的有机聚硅氧烷作为粘合促进剂;

和0.5重量份式所示的硅灭鼠作为粘合促进剂,

然后,混合铂的1,3-二乙烯基四甲基二硅氧烷络合物的1,3-二乙烯基四甲基二硅氧烷溶液(在本发明的组合物中,在络合物内的金属铂含量为5ppm重量单位),生产粘度为70000mPa.s的硅橡胶组合物(V)。

将硅橡胶组合物(V)夹在50微米厚的聚对苯二甲酸乙二酯膜(在该膜表面上具有2微米厚的聚酯砜树脂层)和50微米厚聚对苯二甲酸乙二酯树脂膜(在该膜表面上具有2微米厚的乙酸纤维素树脂层)之间,然后在对流烘箱内,在80℃下加热30分钟固化,同时通过具有调节的间隙的两个不锈钢辊保持以上提及的硅橡胶组合物的厚度在30微米,从而得到硅氧烷基粘合片材(M)。

剥离掉在硅氧烷基粘合片材(L)的硅橡胶层上的保护膜,并在切割成小方之前,使用橡胶辊牢固地粘接到4英寸的硅晶片上。接下来,在100℃下,加热所得物30分钟,和仅仅粘接硅橡胶层与硅晶片。接下来,将厚度为90微米的粘合片材层压到牢固地粘接到硅氧烷基粘合片材(L)上的保护膜上,所述硅氧烷基粘合片材(L)本身被粘接到硅晶片上,和使用由Disco Corporation制造的切割锯DAD 340,将该产品在一侧切割成10mm的正方形。切掉粘合片材的底表面,从而留下60微米。

当使用粘合片材粘着切割的半导体芯片时,保护膜保持在粘合片材侧上。通过其中在室温下,在1.0MPa的压力下,将粘接到半导体芯片上的硅氧烷基粘合片材经1秒钟压制粘接到不规则度为20微米、由玻璃纤维增强的环氧树脂制造的板的布线表面上,和在150℃下加热所得物60分钟,以使粘土状硅橡胶组合物层固化的方法,从而生产器件。

测量该器件的总厚度,和通过减去硅芯片和由玻璃纤维增强的环氧树脂制造的板的厚度,测量在芯片的四个角处硅氧烷粘合层的厚度,于是发现在所有情况下,硅氧烷粘合层的厚度均匀为48微米。向上牵拉硅芯片,以证实粘合性,和发现硅氧烷粘合层经历内聚破坏,从而证实粘合性令人满意。

剥离掉在硅橡胶基粘合片材(M)的硅橡胶层上的保护膜(该聚对苯二甲酸乙二酯膜在该膜的表面上具有乙酸纤维素树脂层),并在切割成小片之前,使用橡胶辊牢固地粘接到4英寸的硅晶片上。接下来,在100℃下,加热所得物30分钟,和仅仅粘接硅橡胶层与硅晶片。接下来,将厚度为90微米的粘合片材层压到牢固地粘接到硅氧烷基粘合片材(M)上的保护膜上,所述硅氧烷基粘合片材(M)本身被粘接到硅晶片上,和使用由Disco Corporation制造的切割锯DAD 340,将该产品在一侧切割成5mm的正方形。切掉粘合片材的底表面,从而留下60微米。

当使用粘合片材粘着切割的半导体芯片时,保护膜保持在粘合片材侧上。通过其中在室温下,在1.0MPa的钟压力下,将粘接到半导体芯片上的硅氧烷基粘合片材(M)经1秒压制粘接到所述半导体芯片上,而所述半导体芯片通过在由玻璃纤维增强的环氧树脂制造的板的布线表面上的硅氧烷基粘合片材(L)粘接,然后在150℃下加热所得物60分钟,从而生产器件。

接下来,通过超声热压缩粘接,将直径为30微米的金属布线粘接到以上提及的器件上,产生图5所示的半导体器件。使30个这些半导体器件在-50℃下静置30分钟,然后立即进行热循环试验,其中在150℃下静置30分钟为1次循环,和评价以上提及的器件的缺陷导电分数。结果见表1。

表1

本发明的硅氧烷基粘合片材的特征在于,它可满意地粘接到光滑基体和在表面上具有不规则度的基体上,和可使得粘接层的厚度均匀。特别地,本发明的硅氧烷基粘合片材适于粘接在至少一个表面上具有不规则度的半导体芯片和芯片连接元件上。本发明粘接半导体芯片和芯片连接元件的方法的特征在于:即使半导体芯片和芯片连接元件在至少一个表面上具有不规则度,也可满意地粘接它们。本发明的半导体器件的特征在于,即使半导体芯片和芯片连接元件在至少一个表面上具有不规则度,也可优异可靠地满意地粘接它们。

Claims (26)

1.一种硅氧烷基粘合片材,它包括在所述片材的一侧上的粘土状可固化硅氧烷组合物的第一层,和在所述片材的另一侧上的固化速度慢于所述第一层的粘土状硅氧烷组合物的第二层,其中硅氧烷组合物的第二层的90%硫化时间与硅氧烷组合物的第一层的90%硫化时间之比在130℃下为5倍或更大,其中所述90%硫化时间是根据JIS K6300的规定,使用振荡硫化测试仪进行的硫化试验而测定的。

2.权利要求1的硅氧烷基粘合片材,其中任何一种所述的粘土状可固化硅氧烷组合物的根据JIS K 6249规定的可塑值为100-800。

3.权利要求1的硅氧烷基粘合片材,其中任何一种所述的粘土状可固化硅氧烷组合物是可氢化硅烷化固化的硅氧烷组合物。

4.权利要求3的硅氧烷基粘合片材,其中任何一种所述的可氢化硅烷化固化的硅氧烷组合物是包含(A)每一分子具有至少两个链烯基的有机聚硅氧烷、(B)填料、(C)每一分子具有至少两个与硅键合的氢原子的有机聚硅氧烷、(D)粘合促进剂和(E)氢化硅烷化催化剂的可固化硅氧烷组合物。

5.权利要求1的硅氧烷基粘合片材,进一步包括在硅氧烷基粘合片材的至少一侧上的保护膜。

6.一种硅氧烷基粘合片材,它包括在所述片材的一侧上的粘合固化硅氧烷层,和在所述片材的另一侧上的粘土状可固化硅氧烷组合物层。

7.权利要求6的硅氧烷基粘合片材,其中所述粘土状可固化硅氧烷组合物的根据JIS K 6249规定的可塑值为100-800。

8.权利要求6的硅氧烷基粘合片材,其中所述粘土状可固化硅氧烷组合物是可氢化硅烷化固化的硅氧烷组合物。

9.权利要求8的硅氧烷基粘合片材,其中所述可氢化硅烷化固化的硅氧烷组合物包含(A)每一分子具有至少两个链烯基的有机聚硅氧烷、(B)填料、(C)每一分子具有至少两个与硅键合的氢原子的有机聚硅氧烷、(D)粘合促进剂和(E)氢化硅烷化催化剂。

10.权利要求6的硅氧烷基粘合片材,进一步包括在硅氧烷基粘合片材的至少一侧上的保护膜。

11.一种将半导体芯片粘接到芯片连接元件上的方法,该方法包括步骤:

(1)通过将层压体切割成小片,生产半导体芯片,其中所述层压体包括粘接到晶片上的固化硅氧烷层、牢固地粘接到所述固化硅氧烷层上的粘土状可固化硅氧烷组合物层、牢固地粘接到所述粘土状可固化硅氧烷组合物层上的保护膜和用粘合剂连接到膜上的片材;

(2)从所述芯片上剥离所述保护膜和所述片材;

(3)通过用所述粘土状可固化硅氧烷组合物层压制所述半导体芯片到所述芯片连接元件上,而将所述半导体芯片粘接到所述芯片连接元件上;和

(4)固化所述粘土状可固化硅氧烷组合物层。

12.权利要求11的方法,其中通过施加粘土状可固化硅氧烷组合物(I)的第一层到晶片上,施加具有低于第一层固化速度的粘土状可固化硅氧烷组合物(II)的第二层,和固化第一层,以便防止组合物(II)的层固化,从而形成固化的硅氧烷层和牢固地粘接到该固化硅氧烷层上的粘土状可固化硅氧烷组合物层。

13.权利要求12的方法,其中任何一种所述的粘土状可固化硅氧烷组合物的根据JIS K 6249规定的可塑值为100-800。

14.权利要求12的方法,其中粘土状可固化硅氧烷组合物(I)或粘土状可固化硅氧烷组合物(II)是可氢化硅烷化固化的硅氧烷组合物。

15.权利要求14的方法,其中任何一种所述的可氢化硅烷化固化的硅氧烷组合物是包含至少(A)每一分子具有至少两个链烯基的有机聚硅氧烷、(B)填料、(C)每一分子具有至少两个与硅键合的氢原子的有机聚硅氧烷、(D)粘合促进剂和(E)氢化硅烷化催化剂的可固化硅氧烷组合物。

16.一种制造半导体器件的方法,所述半导体器件包括半导体芯片、硅氧烷基粘合片材和半导体芯片连接元件,其中该方法包括:

a)制造硅氧烷基粘合片材,它在一侧上具有粘土状可固化硅氧烷组合物(I)的第一层,和在另一侧上具有固化速度慢于所述组合物(I)的第一层的粘土状可固化硅氧烷组合物(II)的第二层,和

b)固化所述组合物(I)的第一层,以便在所述组合物(I)的第一层保持与半导体芯片接触的同时,所述组合物(II)的第二层仍然未固化,和随后在所述组合物(II)的第二层保持与半导体芯片连接元件接触的同时,所述组合物(II)的第二层固化。

17.一种制造半导体器件的方法,所述半导体器件包括半导体芯片、硅氧烷基粘合片材和半导体芯片连接元件,其中该方法包括:

a)制造硅氧烷基粘合片材,它在一侧上具有粘土状可固化硅氧烷组合物(I)的第一层,和在另一侧上具有固化速度慢于所述组合物(I)的第一层的粘土状可固化硅氧烷组合物(II)的第二层,和

b)固化所述组合物(I)的第一层,以便在所述组合物(I)的第一层保持与半导体芯片连接元件接触的同时,所述组合物(II)的第二层仍然未固化,和随后在所述组合物(II)的第二层保持与半导体芯片接触的同时,所述组合物(II)的第二层固化。

18.权利要求16或17的方法,其中任何一种所述的粘土状可固化硅氧烷组合物的根据JIS K 6249规定的可塑值为100-800。

19.权利要求16或17的方法,其中任何一种所述的粘土状可固化硅氧烷组合物是可氢化硅烷化固化的硅氧烷组合物。

20.权利要求19的方法,其中所述可氢化硅烷化固化的硅氧烷组合物包含至少(A)每一分子具有至少两个链烯基的有机聚硅氧烷、(B)填料、(C)每一分子具有至少两个与硅键合的氢原子的有机聚硅氧烷、(D)粘合促进剂和(E)氢化硅烷化催化剂。

21.一种制造半导体器件的方法,所述半导体器件包括半导体芯片、硅氧烷基粘合片材和半导体芯片连接元件,其中硅氧烷基粘合片材包括在一侧上的固化硅氧烷层和在另一侧上的粘土状可固化硅氧烷组合物层,其中该方法包括:

a)粘接所述固化的硅氧烷层,以便在所述固化的硅氧烷层保持与半导体芯片接触的同时,粘土状可固化硅氧烷组合物层仍然未固化,和随后

b)在所述粘土状可固化硅氧烷组合物层保持与半导体芯片连接元件接触的同时,固化所述粘土状可固化硅氧烷组合物层。

22.一种制造半导体器件的方法,所述半导体器件包括半导体芯片、硅氧烷基粘合片材和半导体芯片连接元件,其中硅氧烷基粘合片材包括在一侧上的固化硅氧烷层和在另一侧上的粘土状可固化硅氧烷组合物层,其中该方法包括:

a)粘接所述固化的硅氧烷层,以便在所述的固化硅氧烷层保持与半导体芯片连接元件接触的同时,粘土状可固化硅氧烷组合物层仍然未固化,和随后

b)在所述粘土状可固化硅氧烷组合物层保持与所述半导体芯片接触的同时,固化所述粘土状可固化硅氧烷组合物层。

23.权利要求21或22的方法,其中所述的粘土状可固化硅氧烷组合物的根据JIS K 6249规定的可塑值为100-800。

24.权利要求21或22的方法,其中所述的粘土状可固化硅氧烷组合物是可氢化硅烷化固化的硅氧烷组合物。

25.权利要求24的方法,其中所述可氢化硅烷化固化的硅氧烷组合物包含(A)每一分子具有至少两个链烯基的有机聚硅氧烷、(B)填料、(C)每一分子具有至少两个与硅键合的氢原子的有机聚硅氧烷、(D)粘合促进剂和(E)氢化硅烷化催化剂。

26.通过权利要求16、17、21或22的方法制备的半导体器件。

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP205869/2002 | 2002-07-15 | ||

| JP2002205869 | 2002-07-15 | ||

| PCT/JP2003/008936 WO2004007628A1 (en) | 2002-07-15 | 2003-07-14 | Silicone-based adhesive sheet, method of bonding a semiconductor chip to a chip attachment component, and a semiconductor device |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN1668715A CN1668715A (zh) | 2005-09-14 |

| CN1276046C true CN1276046C (zh) | 2006-09-20 |

Family

ID=30112779

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CNB038168367A Expired - Fee Related CN1276046C (zh) | 2002-07-15 | 2003-07-14 | 硅氧烷基粘合片材、将半导体芯片粘接到芯片连接元件上的方法,和半导体器件 |

Country Status (8)

| Country | Link |

|---|---|

| US (1) | US7534659B2 (zh) |

| EP (1) | EP1539898A1 (zh) |

| JP (1) | JP2004043814A (zh) |

| KR (1) | KR20050021485A (zh) |

| CN (1) | CN1276046C (zh) |

| AU (1) | AU2003249594A1 (zh) |

| TW (1) | TWI293191B (zh) |

| WO (1) | WO2004007628A1 (zh) |

Families Citing this family (26)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP4536367B2 (ja) * | 2003-12-24 | 2010-09-01 | 東レ・ダウコーニング株式会社 | ダイシングダイボンディング用シート及びその製造方法 |

| JP2006005159A (ja) * | 2004-06-17 | 2006-01-05 | Shin Etsu Chem Co Ltd | ダイシング・ダイボンド用接着テープ |

| JP4676735B2 (ja) | 2004-09-22 | 2011-04-27 | 東レ・ダウコーニング株式会社 | 光半導体装置の製造方法および光半導体装置 |

| JP4664032B2 (ja) | 2004-10-13 | 2011-04-06 | 東レ・ダウコーニング株式会社 | シリルアルコキシメチルハライドの製造方法 |

| JP4849814B2 (ja) | 2005-03-29 | 2012-01-11 | 東レ・ダウコーニング株式会社 | ホットメルト型シリコーン系接着剤 |

| JP4828146B2 (ja) | 2005-03-30 | 2011-11-30 | 東レ・ダウコーニング株式会社 | 熱伝導性シリコーンゴム組成物 |

| JP4828145B2 (ja) | 2005-03-30 | 2011-11-30 | 東レ・ダウコーニング株式会社 | 熱伝導性シリコーンゴム組成物 |

| JP5004433B2 (ja) | 2005-04-27 | 2012-08-22 | 東レ・ダウコーニング株式会社 | 硬化性シリコーン組成物およびその硬化物 |

| JP4931366B2 (ja) | 2005-04-27 | 2012-05-16 | 東レ・ダウコーニング株式会社 | 硬化性シリコーン組成物および電子部品 |

| TWI409309B (zh) * | 2005-10-04 | 2013-09-21 | Dow Corning Taiwan Inc | 供織物塗佈之液體聚矽氧橡膠組合物 |

| DE102006009394A1 (de) * | 2006-03-01 | 2007-09-06 | Andreas Jakob | Mehrlagenschichtsystem mit einer Schicht als Trennschicht zum Trägern von dünnen Wafern bei der Halbleiterherstellung |

| WO2007099146A1 (de) * | 2006-03-01 | 2007-09-07 | Jakob + Richter Ip-Verwertungsgesellschaft Mbh | Verfahren zum bearbeiten insbesondere dünnen der rückseite eines wafers, wafer-träger-anordnung hierfür und verfahren zur herstellung einer solchen wafer-träger-anordnung |

| JP5285846B2 (ja) | 2006-09-11 | 2013-09-11 | 東レ・ダウコーニング株式会社 | 硬化性シリコーン組成物および電子部品 |

| JP2010509088A (ja) * | 2006-11-08 | 2010-03-25 | 東レ・ダウコーニング株式会社 | 立体成型品及びその製造方法並びにその用途 |

| JP5284143B2 (ja) * | 2009-03-02 | 2013-09-11 | 本田技研工業株式会社 | 燃料電池用接着剤及びこれを用いた膜電極構造体 |

| JP2010284869A (ja) * | 2009-06-11 | 2010-12-24 | Shin-Etsu Chemical Co Ltd | 接合部材 |

| DE102013225109A1 (de) * | 2013-12-06 | 2015-06-11 | Robert Bosch Gmbh | Verfahren zum Befestigen eines Mikrochips auf einem Substrat |

| DE102014219095A1 (de) * | 2014-09-22 | 2016-03-24 | Nissan Chemical Industries, Ltd. | Wafer-Träger-Anordnung |

| CN104485304B (zh) * | 2015-01-07 | 2018-03-20 | 海太半导体(无锡)有限公司 | 一种芯片黏着检测装置 |

| JP2017050322A (ja) * | 2015-08-31 | 2017-03-09 | Jsr株式会社 | 基材の処理方法、半導体装置およびその製造方法 |

| CN107346746B (zh) * | 2016-05-05 | 2020-09-08 | 中芯国际集成电路制造(上海)有限公司 | 一种半导体器件及其制造方法和电子装置 |

| WO2018027108A1 (en) * | 2016-08-05 | 2018-02-08 | Marsh Stephen Alan | Micro pressure sensor |

| WO2018148282A1 (en) | 2017-02-08 | 2018-08-16 | Elkem Silicones USA Corp. | Secondary battery pack with improved thermal management |

| GB2564188B (en) * | 2017-04-24 | 2022-02-09 | Fuji Polymer Ind | Silicone sheet and mounting method using the same |

| TWI762649B (zh) | 2017-06-26 | 2022-05-01 | 日商杜邦東麗特殊材料股份有限公司 | 黏晶用固化性矽組合物 |

| CN110350061A (zh) * | 2019-07-10 | 2019-10-18 | 佛山市国星半导体技术有限公司 | 一种免用封装胶的led芯片、封装器件及封装方法 |

Family Cites Families (37)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3284406A (en) * | 1963-12-18 | 1966-11-08 | Dow Corning | Organosiloxane encapsulating resins |

| US3457214A (en) * | 1965-12-15 | 1969-07-22 | Gen Electric | Low temperature vulcanizing composition and article made therefrom |

| US3436366A (en) * | 1965-12-17 | 1969-04-01 | Gen Electric | Silicone potting compositions comprising mixtures of organopolysiloxanes containing vinyl groups |

| BE759624A (fr) * | 1969-12-01 | 1971-06-01 | Dow Corning | Caoutchouc de silicone resistant aux salissures et sa fabrication |

| US3989790A (en) * | 1974-03-22 | 1976-11-02 | Sws Silicones Corporation | Method for preparing silicone rubber molds |

| US4163082A (en) * | 1978-10-23 | 1979-07-31 | Dow Corning Corporation | U.V.-radiation method for decreasing surface tack of disposed organopolysiloxane greases and gels |

| US4297265A (en) * | 1979-11-23 | 1981-10-27 | Otto Fabric, Inc. | Silicone rubber coating material having reduced surface tension |

| JPS5952910B2 (ja) * | 1980-12-26 | 1984-12-21 | 東芝シリコ−ン株式会社 | 常温硬化性ポリオルガノシロキサン組成物 |

| US4746699A (en) * | 1983-07-07 | 1988-05-24 | General Electric Company | Curable silicone compositions |

| US4500584A (en) * | 1983-07-07 | 1985-02-19 | General Electric Company | Transparent membrane structures |