Fall 2004 - National Ready Mixed Concrete Association

Fall 2004 - National Ready Mixed Concrete Association

Fall 2004 - National Ready Mixed Concrete Association

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

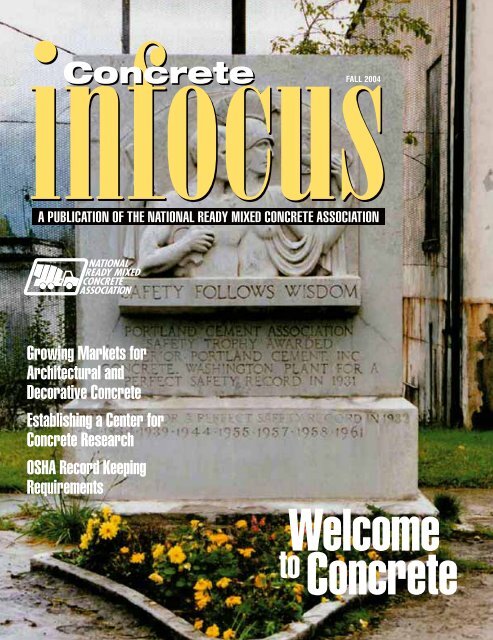

infocus<br />

<strong>Concrete</strong><br />

FALL <strong>2004</strong><br />

A PUBLICATION OF THE NATIONAL READY MIXED CONCRETE ASSOCIATION<br />

Growing Markets for<br />

Architectural and<br />

Decorative <strong>Concrete</strong><br />

Establishing a Center for<br />

<strong>Concrete</strong> Research<br />

OSHA Record Keeping<br />

Requirements<br />

Welcome<br />

<strong>Concrete</strong><br />

to

Trimble Mobile Solutions, Inc.<br />

14301 G. Sullyfield Circle<br />

Chantilly, VA 20151<br />

703.502.8125

infocus<br />

<strong>Concrete</strong><br />

<strong>Concrete</strong> in FOCUS is<br />

published for:<br />

<strong>National</strong> <strong>Ready</strong> <strong>Mixed</strong><br />

<strong>Concrete</strong> <strong>Association</strong><br />

900 Spring Street<br />

Silver Spring, Maryland 20910<br />

Phone: (301) 587-1400<br />

Fax: (301) 585-4219<br />

www.nrmca.org<br />

Chairman:<br />

Hardy Johnson<br />

First Vice Chairman:<br />

Hale Ritchie<br />

Second Vice Chairman:<br />

Peter Brewin<br />

Treasurer:<br />

Mark Stiles<br />

President:<br />

Robert A. Garbini, P.E.<br />

Managing Editor:<br />

Kathleen Carr-Smith<br />

<strong>Association</strong> Editor:<br />

Frank Cavaliere<br />

Published by:<br />

Naylor Publications, Inc.<br />

5950 NW 1st Place<br />

Gainesville, Florida 32607<br />

Phone: (352) 332-1252<br />

(800) 369-6220<br />

Fax: (352) 331-3525<br />

www.naylor.com<br />

Publisher: Chris Hodges<br />

Editor: Ruth Ellen Rasche<br />

Sales Manager: Tom Schell<br />

Research: Tim Liney<br />

Book Manager: Doug Folkerth<br />

Account Representatives:<br />

Lou Brandow, Krys D’Antonio,<br />

Ryan Griffin, Mary Johnston,<br />

Josh Nye, Christine Ricci,<br />

Mike Scott, Bernard Spencer,<br />

Jamie Williams and<br />

Lonnie Williams<br />

Layout and Design:<br />

Calvin Harding<br />

Advertising Art:<br />

Melanie Meilleur<br />

©<strong>2004</strong> Naylor Publications, Inc.<br />

All rights reserved. The contents<br />

of this publication may not be<br />

reproduced by any means, in<br />

whole or in part, without the<br />

prior written consent of the<br />

publisher.<br />

FALL <strong>2004</strong>, VOL.3, NO. 3<br />

contents<br />

features<br />

10 Welcome to <strong>Concrete</strong><br />

18 Growing Markets for Architectural and<br />

Decorative <strong>Concrete</strong><br />

26 Establishing a Center for <strong>Concrete</strong> Research<br />

36 OSHA Record Keeping Requirements for<br />

Injuries and Illnesses<br />

40 Business Models in a Consolidating <strong>Ready</strong><br />

<strong>Mixed</strong> <strong>Concrete</strong> Industry<br />

48 Shrinkage-Reducing Admixtures Control<br />

<strong>Concrete</strong> Curling in Super-Flat Floors<br />

62 Ultra-Thin Whitetopping Revives Faltering<br />

Pavements<br />

departments<br />

6 Capitol Comment:<br />

Get Out the Vote!<br />

8 Corporate Suite:<br />

Getting the Most from Your People<br />

16 Truck Tracs:<br />

<strong>Ready</strong> <strong>Mixed</strong> <strong>Concrete</strong> Driver Simulators<br />

29 Environmental Scene:<br />

To LEED or Not to LEED<br />

30 Tech Talk:<br />

Understanding the LEED Credit for Recycled Content<br />

38 Safety First:<br />

The OSHA Inspection – Are You <strong>Ready</strong><br />

47 Equipment Talk:<br />

And What Color Would You Like That In…<br />

The Color-<strong>Concrete</strong> Boom<br />

58 Education Matters:<br />

Sales Manager as Coach<br />

64 Workforce Issues Q & A<br />

73 Index to Advertisers<br />

Published September <strong>2004</strong><br />

NRC-Q0304/9365<br />

4 ı FALL <strong>2004</strong>

capitol comment<br />

Get Out The Vote!<br />

The Outcome of This Year’s Elections<br />

Could Be in YOUR Hands<br />

By Jennifer LeFevre, Director of Government Relations, NRMCA<br />

One would expect once-in-a-lifetime<br />

events to be exactly that – once in a<br />

lifetime. However, that has not<br />

been the case over the last two major elections<br />

in 2000 and 2002. No one needs to<br />

rehash the 2000 Election Day debacle in<br />

Florida but the major point needs to be<br />

underscored just the same: every single vote<br />

matters – not only in the presidential election<br />

but in all elections. The national elections<br />

in 2000 and 2002 were the closest in<br />

history and history could repeat itself again<br />

this November. And some outcomes could<br />

be in your hands.<br />

Although voter registration of eligible<br />

voters and overall voter turnout in the United<br />

States has decreased to pathetic levels<br />

(hovering around a 50 percent voting rate of<br />

all eligible voters) for an industrialized,<br />

democratic society, the trend of elections<br />

becoming closer and closer has increased significantly<br />

over the last couple of decades. In<br />

fact, in 2000 and 2002, a significant number<br />

of congressional races (both House and Senate)<br />

were decided by a fraction of a percentage<br />

point and, in some cases, by fewer than a<br />

couple of hundred votes. Given the close<br />

party margins in both chambers of Congress,<br />

the following question is worth asking:<br />

can you, your family or your employees really<br />

afford to leave such important decisions –<br />

electing lawmakers – up to others<br />

Many people note lack of time or business<br />

travel as an excuse for not participating<br />

in elections. However, they forget the terrific<br />

option of utilizing early in-person or absentee<br />

ballot voting. Voter registration deadlines<br />

don’t even commence until October and<br />

many states allow voters to apply for absentee<br />

ballots well into October. A full 25 states<br />

do not even require ANY reason for utilizing<br />

absentee ballots. If there is any chance you<br />

may be out of town on Election Day, why<br />

not at least apply for an absentee ballot<br />

Electronic communications make doing so<br />

easier than ever. To access information on<br />

obtaining voter registration materials or<br />

absentee ballot information, please visit<br />

www.nrmca.org and log on to our grassroots<br />

page to get state-specific information.<br />

NRMCA staff is also available to answer any<br />

questions you may have. So, come this<br />

November 2nd, don’t forget to exercise your<br />

civic duty and GET OUT THE VOTE! ■<br />

What Can You Communicate to<br />

Employees Regarding Elections<br />

• Information about registering to vote,<br />

including deadlines and time frames<br />

• Information about using absentee ballots,<br />

including deadlines and time frames<br />

• You can make voter registration documents<br />

available to employees<br />

• You can direct employees to county facilities<br />

to register to vote<br />

• You can provide employees with time to<br />

vote on Election Day<br />

6 ı FALL <strong>2004</strong>

the corporate suite<br />

Getting the Most<br />

from Your People:<br />

What Color Are You<br />

By Jay Gubrud<br />

The paradox of being a leader is that<br />

while your people can be your<br />

biggest asset, they can also be your<br />

biggest liability. They open the doors each<br />

day, serve your customers and play essential<br />

roles in your organizations. Without them,<br />

your business could not run. At the same<br />

time, they provide the biggest challenge in<br />

running an efficient and effective organization.<br />

If you do not have the support of the<br />

people around you, then it will be nearly<br />

impossible to accomplish your mission.<br />

The easiest way to get their support is to<br />

enhance your relationship with them. The<br />

Golden Rule says, “Treat others how you<br />

would like to be treated.” Most of us are<br />

familiar with the Golden Rule. It is a great<br />

rule, yet in my opinion, it can be improved<br />

upon. The challenge to the Golden Rule is<br />

that there are many personality types. Those<br />

TYPE CLUES NEEDS<br />

Yellow Center of attention Public applause<br />

(Popular) Relationship driven Approval<br />

Adaptive<br />

Attention<br />

Understand big picture<br />

different types have different values, beliefs<br />

and preferences. There are 1440 personality<br />

inventory tools on the market and if you<br />

boil down most of them, you find there are<br />

four major categories of personalities. Each<br />

category has different needs. As a result, the<br />

best way to treat others is how they want to<br />

be treated.<br />

The reality is that we can get what we<br />

want as a manager or director by giving others<br />

what they want. Treat them in a way that<br />

appeals to their values, beliefs and preferences.<br />

Think about it! If someone were to<br />

come up to you and offer to give you something<br />

that you needed, how would you<br />

react If someone offered to help you on a<br />

project or take some of your workload off<br />

your hands, how would you feel about that<br />

person In most cases, you would be<br />

Blue Well dressed Have to be organized or it bothers them emotionally<br />

(Perfect) Orderly Understand their sensitivity<br />

Reserved<br />

Respect their personal space<br />

Specifics<br />

Red Bottom line Answers to questions<br />

(Powerful) Sense of urgency Acknowledge that they did a task<br />

Goal driven<br />

Are usually right<br />

Need to control<br />

White Understanding driven Information<br />

(laid back) Creative Appreciate the person for who they are<br />

Seeks information Show respect<br />

Advance notice<br />

Source: The Color Code by Taylor Hartman Ph.D.<br />

thrilled. Beyond that, you would probably<br />

want to give something back to them. It is a<br />

win/win situation.<br />

The same holds true for personalities.<br />

Each personality has a preferred mode of<br />

operating. When we communicate and<br />

interact with that person in a way that connects<br />

with their preferred mode, then the<br />

communication has been more effective.<br />

A gentleman I know works for an international<br />

agricultural company. He works handin-hand<br />

with a wide variety of personalities.<br />

His boss is a take-charge and bottom-line personality<br />

(Red). When he communicates with<br />

his boss, he gets straight to the point and is<br />

fully prepared. He also has to interact with an<br />

operations person that is laid back (White).<br />

When interacting with the operations person,<br />

he provides more detail and plenty of advance<br />

notice. As a result, he has maintained exceptional<br />

relationships with a diverse group of<br />

coworkers. And his division benefits from<br />

that cohesiveness.<br />

If you want to see big improvements in<br />

the effectiveness of your organization, especially<br />

during times of mergers, doing more<br />

with less and shrinking margins, take control<br />

of one of the few things you can control —<br />

how you communicate with the people<br />

around you. Take some time to identify the<br />

personality types you work with and start<br />

giving them what they need. Better yet, try<br />

this with one of your more difficult employees<br />

and see how things change. I promise<br />

that if you actually try it, you will see the<br />

results quickly.<br />

■<br />

For more than seven years, Jay Gubrud has<br />

helped associations, their boards and members<br />

eliminate roadblocks to success. His theme is<br />

very unique and one everybody can relate<br />

to...cars and driving! You can reach him at<br />

www.jaygubrud.com or 651/635-9939.<br />

8 ı FALL <strong>2004</strong>

feature<br />

Welcome to<br />

Located among the firs tucked along the<br />

Cascade Mountains of Washington is a<br />

locality known more for its abundance<br />

of fine fishing and deer hunting than its past.<br />

Situated on the banks of the Baker River where<br />

it joins the Skagit, it is winter home of nesting<br />

bald eagles. The town’s time has come and<br />

gone, but still pulsates with the energy of any<br />

small community located far from the hustle<br />

and bustle of major metropolitan cities. Life is<br />

slower; everyone knows your name, and the<br />

Friday night high school football games play to<br />

a faithful crowd. The high school teams are<br />

known as the “<strong>Concrete</strong> Lions.” But this town<br />

has a different, more unique story; one rich in<br />

the history of building these metropolitan<br />

cities, one that helped shape the development<br />

of the Pacific Northwest, and it was all built on<br />

cement and concrete.<br />

The town of “<strong>Concrete</strong>” was the site of<br />

Washington State’s first cement production<br />

facility. Founded on a deep and rich deposit of<br />

limestone and clay, the town became the center<br />

for manufacturing Portland cement. At its<br />

peak, there were six kilns in operation with a<br />

combined capacity of 5,200 bbl per day, each<br />

powered by sub bituminous coal purchased by<br />

rail from the Bellingham Coal Company.<br />

Limestone was first transported from the quarry<br />

to the mill by a two-mile standard gauge<br />

railway and sometime before 1930, converted<br />

10 ı FALL <strong>2004</strong>

<strong>Concrete</strong><br />

By<br />

Bruce Chattin,<br />

Washington Aggregates &<br />

<strong>Concrete</strong> <strong>Association</strong><br />

to an aerial tramway with a capacity of 260<br />

tons per hour.<br />

When in full operation, as many as 200<br />

men were employed, but the average workforce<br />

was 160. With a population of 1,000<br />

(circa 1930), it wasn’t hard to figure out<br />

what was at the core of this small town —<br />

Portland cement.<br />

The Washington Portland Cement company<br />

began construction on its new plant<br />

June 1, 1905 and produced its first cement<br />

in May, 1907. But growth and plenty of<br />

future made the need for a second cement<br />

plant necessary. Another driving factor was<br />

the planned “Chittenden locks” just outside<br />

of Seattle so ships could pass from Puget<br />

Sound out to sea. A second cement plant<br />

was built; Superior Cement began to manufacture<br />

Portland cement in 1908. The Superior<br />

Plant employed the dry process<br />

originally, but later converted to the wet<br />

process in 1917. In 1918, the Superior<br />

CONCRETE in focus ı 11

feature<br />

Cement Company purchased the Washington<br />

Cement Company and shut down its<br />

plant. Superior Cement then became the<br />

oldest cement plant operating in the state of<br />

Washington. The plant continued under the<br />

operation of Lone Star Cement until 1967<br />

and the business office remained in operation<br />

until 1973 when the plant formally<br />

shut down.<br />

But the story doesn’t stop there. It could<br />

be urban legend or just the historical pride<br />

of the town and the competitive nature of its<br />

workers. As the West was expanding, pioneers<br />

came to the Baker area in the late<br />

1800s and settled on the banks of the Baker<br />

River sometime around 1871. Washington<br />

didn’t become a state until 1889. In 1890,<br />

the town site was officially platted and businesses<br />

began to grow under the name of<br />

“Baker,” Wash. But across the river, the new<br />

Washington Portland Cement settlement<br />

grew up and became known as “Cement<br />

City.” It seems the town took on the personality<br />

and ownership of its favorite industry.<br />

Story has it “Star Cement” was a brand<br />

name of one of the cement companies and<br />

each town hailed from under each name,<br />

“Star City” and “Cement City.” In 1909,<br />

after much debate, the new community<br />

finally settled on the name of “<strong>Concrete</strong>.”<br />

In fact, as you walk along Main Street, a<br />

short section of town that still houses the<br />

original structures, it seems there was another<br />

reason why this little town took on the<br />

name of <strong>Concrete</strong>. In or before 1920, at<br />

least once and possibly twice, the town or<br />

parts of it burned down. And each time they<br />

rebuilt it, except the last time. They decided<br />

that rather than continue this self-imposed<br />

building boom they would build it differently.<br />

And they did — in concrete. The liquor<br />

store and bank each have signs today that<br />

indicate when they last rebuilt the structure,<br />

only this time for good and the structures<br />

still stand today.<br />

When you visit “<strong>Concrete</strong>” today,<br />

although the great limestone giants have<br />

12 ı FALL <strong>2004</strong>

GivenHansco has the power of one.<br />

COMPUCRETE ® ACCOUNTING<br />

Quote System<br />

Inventory<br />

Scale Ticketing<br />

<strong>Ready</strong> Mix Ticketing<br />

Point-of-Sale<br />

Accounts<br />

Receivable<br />

PLUS<br />

Accounts<br />

Payable<br />

General<br />

Ledger<br />

Cash<br />

Management<br />

Payroll<br />

"GivenHansco<br />

cut our billing<br />

time in half."<br />

Aless Hall<br />

Lone Wolf Enterprises<br />

One Source<br />

One Contact Point<br />

We cover you from start to<br />

financials. You truly make one<br />

call to one vendor if the need<br />

arises. We're here for your<br />

questions about upgrading a<br />

batch control, expanding your<br />

dispatch system, enhancing<br />

your computer network or<br />

finishing your year end<br />

accounting close.<br />

One Relationship<br />

Our relationship with you is<br />

our number one priority. We<br />

embrace a customer first<br />

philosophy. Valuable ongoing<br />

customer input drives our<br />

development and helps refine<br />

our products.<br />

Order Entry<br />

Truck Scheduling<br />

Truck Tracking<br />

DISPATCH ONE<br />

COMPUCRETE ® CONTROLS<br />

Plant Control<br />

One Application<br />

Each GivenHansco application<br />

is a complete package, yet<br />

readily integrates with all of our<br />

other applications. Buy one now<br />

and add others as your business grows.<br />

Producers rely on us for their controls, dispatch software,<br />

industry specific full financial* accounting software,<br />

E-Reporting, and for Information Technology<br />

hardware and networking services.<br />

Mixer Control<br />

Material<br />

Handling<br />

Order Entry<br />

For product information call toll-free<br />

1 866 310 0060<br />

GIVEN<br />

HANSCO<br />

*CompuCrete software is the only full financial accounting package made for producers by one vendor<br />

... your source for Controls, Dispatch, Accounting and IT Services<br />

CONCRETE in focus ı 13

feature<br />

come and gone, the town remembers its origins. As you enter the<br />

town on Hwy. 20, slow down because there is a well-known speed<br />

trap there. And yes, the “<strong>Concrete</strong> police” will get you. Been there,<br />

done that…<br />

The first things you see are the old silos with “Welcome to <strong>Concrete</strong>”<br />

proudly yet faintly visible<br />

from the roadway. The open space<br />

surrounding the silos is known as<br />

“Silo Park.” Signs are posted near<br />

the old cement plant facilities<br />

known as “Superior Row” where<br />

concrete remnants of the town’s<br />

history remain: the “Historic Business<br />

Office” and the “Safety Sculpture”<br />

that once greeted visitors<br />

when they entered the site.<br />

Lone Star, now Glacier Northwest,<br />

still plays a role in the small<br />

community, has helped provide<br />

improvements to Silo Park and still<br />

brings customers to visit the very first cement facility in Washington.<br />

In its prime, a “Company Club” was available to anyone who wanted<br />

to visit the plant. The club featured an excellent chef and included<br />

dining quarters and cottages for quests. Glacier Northwest still hosts<br />

guests and customers at the “Clinker Club” after a day of guided<br />

salmon fishing on the Skagit River.<br />

So if you are ever driving west outside of Sedro Wooley out Hwy.<br />

20, and after you slow down from 55 to 20, you’ll enter the Town of<br />

<strong>Concrete</strong>. If you can, catch a football game on a Friday, give a cheer<br />

for the <strong>Concrete</strong> Lions and munch a burger at the drive in. In Washington,<br />

this little town is an interesting part of our history. A history<br />

that helped build and shape the future of the Puget Sound, all based<br />

on the building materials we like to think are the very best: Portland<br />

cement and concrete.<br />

■<br />

For more information, contact Bruce Chattin, executive director<br />

of the Washington Aggregates & <strong>Concrete</strong> <strong>Association</strong>, at<br />

bchattin@washingtonconcrete.org or (206) 878-1622.<br />

The opinions expressed in this article are those of the author and do not necessarily reflect<br />

the opinions of the <strong>National</strong> <strong>Ready</strong> <strong>Mixed</strong> <strong>Concrete</strong> <strong>Association</strong>.<br />

Visit our booth at NRMCA’s<br />

OES Forum (Booth #106)<br />

14 ı FALL <strong>2004</strong>

INDEPENDENCE<br />

PRYOR<br />

★<br />

OGLESBY ★<br />

★ GREENCASTLE<br />

★<br />

■ BETHLEHEM<br />

SELMA ●<br />

INDIANAPOLIS<br />

★<br />

★ ★ CAPE GIRARDEAU<br />

★<br />

★<br />

MARYNEAL<br />

CHATTANOOGA<br />

STOCKERTOWN<br />

▲<br />

New Orleans<br />

BUZZI UNICEM USA<br />

100 Brodhead Road<br />

Suite 230<br />

Bethlehem, PA 18017<br />

610.882.5000<br />

★<br />

▲<br />

●<br />

■<br />

Cement Plant<br />

Grind Plant<br />

Midwest Division Office<br />

Corporate Office<br />

*<strong>2004</strong> Merger of RC Cement and Lone Star Industries<br />

REMOVE UNSAFE VEHICLES<br />

FROM OUR ROADS.<br />

Problem with seats, safety belts,<br />

air bags and child seats<br />

Unsafe or defective steering<br />

components<br />

Problems with fuel systems,<br />

accelerators, carburetors, etc.<br />

Problems with defective<br />

brakes and tires<br />

CALL THE AUTO SAFETY HOTLINE.<br />

800•424•9393<br />

CONCRETE in focus ı 15

truck tracs<br />

<strong>Ready</strong> <strong>Mixed</strong> <strong>Concrete</strong><br />

Driver Simulators:<br />

Training & Assessment at Every Plant…<br />

the Future May be Closer than We Think<br />

By Terry Jones, Irving Materials, Inc.<br />

Simulators for airplane pilots are<br />

commonplace. Every pilot goes thru<br />

extensive simulator training. The<br />

equipment generally cost millions of dollars<br />

but their use is mandatory. In recent years,<br />

simulators have come to the trucking industry.<br />

Many of the major trucking companies<br />

use state-of-the-art technology to train their<br />

professional drivers in the same way that<br />

professional pilots are trained. Driver training<br />

simulators allow drivers to experience<br />

situations that they encounter every day and<br />

also expose them to situations that in reality<br />

would be extremely dangerous with no<br />

other way to practice or assess a driver’s<br />

response.<br />

The <strong>National</strong> <strong>Ready</strong> <strong>Mixed</strong> <strong>Concrete</strong><br />

<strong>Association</strong> first started looking at simulators<br />

when the <strong>Concrete</strong> Delivery Professional<br />

(CDP) program was being developed in<br />

1999. The CDP task force visited Lockheed<br />

Martin, an industry leader in simulator<br />

development, and viewed a state-of-the-art<br />

system. At that time, problems associated<br />

with the cost, industry specific graphics and<br />

availability to individual members could not<br />

be overcome. Earlier this year, the group visited<br />

a GE driver simulator outside of<br />

Atlanta. The prices have come down considerably,<br />

but convenient, on-demand availability<br />

was still an issue.<br />

With hope renewed, a PC-based system<br />

was displayed for the NRMCA Transportation<br />

Safety Task Force in Silver Spring,<br />

Maryland. This low-cost system, designed<br />

for over-the-road carriers, is available at a<br />

cost of less than $5000. While driving the<br />

simulator, drivers have a realistic view of the<br />

terrain and conditions around them. The<br />

driver can see what is in front, behind and to<br />

the sides of their truck. Computer graphics<br />

simulate a variety of traffic and geographic<br />

situations — mountain passes, interstate<br />

highways, small towns, urban areas and rural<br />

roadways are all represented. The system also<br />

simulates various climatic and road conditions,<br />

and supports different trailer types<br />

and weights.<br />

NRMCA staff has been in contact with<br />

the simulator developer. Discussions have<br />

been positive in respect to developing software<br />

and hardware that are ready mixed concrete-industry<br />

specific. The graphics would<br />

depict mixers backing into jobsites, pulling<br />

out from plants, and washing out at<br />

reclaimers as well as other real world conditions.<br />

The next step will be to have a working<br />

draft of software and hardware<br />

configurations for review by the NRMCA<br />

Operations, Environmental and Safety<br />

Committee at their October 3rd meeting in<br />

San Francisco.<br />

■<br />

Jones is safety director for Irving Materials<br />

and can be contacted via email at<br />

imitljones@aol.com.<br />

16 ı FALL <strong>2004</strong>

Driving one is a perk in itself.<br />

The Granite ® mixer combines legendary durability with an amazingly comfortable cab. Add to that the easy<br />

shifting Mack ® T310 MLR transmission, or the optional Allison ® automatic transmission and you have a perfect<br />

mixer to tame any jobsite. The Granite mixer from Mack. Lightweight chassis, an uncompromising work ethic<br />

and a cab that drivers will love to get into. For more details, call 1-800-922-MACK or visit www.macktrucks.com<br />

DRIVEN. BEYOND.<br />

©<strong>2004</strong> Mack Trucks, Inc. All rights reserved. Allison is a registered trademark of General Motors Corporation.

feature<br />

Growing Markets<br />

for Architectural and<br />

Decorative <strong>Concrete</strong><br />

By Jamie Farny, Program Manager, Portland Cement <strong>Association</strong><br />

The decorative market has been<br />

continuing to gain strength in<br />

the past few years, and is often<br />

referred to as the fastest growing segment<br />

of the industry. It’s important for<br />

the attention it brings to concrete construction.<br />

It turns the ubiquitous material<br />

that is taken for granted, or barely<br />

noticed, into the main attraction. Decorative<br />

concrete is to plain concrete as a<br />

luxury edition car is to the base model.<br />

Both vehicles may get you from one<br />

place to another, but who doesn’t want<br />

to look good doing it<br />

Value-Added Products<br />

Architectural and decorative concrete<br />

are premium products. They are<br />

not for every application. They cost a<br />

little more and look a lot better. Sometimes<br />

they add an aspect of safety to a<br />

project. They can be applied to most<br />

types of construction, including commercial,<br />

industrial, retail and residential<br />

buildings. The following list of examples<br />

is by no means complete:<br />

• exterior walls<br />

• retaining walls<br />

• white or colored interior floors<br />

• exterior flatwork, such as driveways,<br />

patios, plazas, pool decks<br />

• curbs and gutters, medians, planters<br />

• bridge parapets and barrier medians<br />

Stamped and colored concrete provides a good-looking pool and spa deck.<br />

18 ı FALL <strong>2004</strong>

This colored concrete garden plaza provides a pleasant outside space for visitors to sit and relax.<br />

This compilation CD contains promotional and technical literature, a presentation, a photo library,<br />

and links to related resources, tools useful in growing anyone’s decorative concrete business.<br />

Stamping concrete has advanced dramatically<br />

since its beginnings. This<br />

concrete has been colored and textured<br />

so that it resembles a natural<br />

slate.<br />

CONCRETE in focus ı 19

feature<br />

Decorative concrete adds curb<br />

appeal to homes. Techniques<br />

used here include stamped and<br />

colored concrete with<br />

interesting joint patterns.<br />

As value-added products, architectural<br />

and decorative concrete can expand producers’<br />

offerings and increase their profit margins.<br />

For consumers, the products are long<br />

lasting and aesthetically pleasing. It’s a winwin<br />

situation for producer and buyer alike.<br />

Where We Started<br />

Several years ago, Portland Cement <strong>Association</strong><br />

formed a White Cement Subcommittee<br />

in response to the increasing interest<br />

in architectural and decorative concrete.<br />

PCA focused on this area because white<br />

cement is the key ingredient for achieving<br />

good results in decorative concrete projects.<br />

A pure white product, it provides the best<br />

base for tinting.<br />

A strategic plan was developed, which<br />

included market research and focus groups<br />

to get an idea of market conditions at that<br />

time. They found that many people who<br />

worked with cement and concrete every<br />

day—architects, engineers, contractors and<br />

ready-mix producers—didn’t even know that<br />

portland cement was available in a white formulation.<br />

So the first obstacle to overcome<br />

was lack of awareness within the construction<br />

industry.<br />

Owners and purchasers were also found<br />

to be largely unaware of the product or its<br />

capabilities. Some thought all concrete was<br />

white. Others didn’t know they could get colored<br />

concrete to take on such a wide range of<br />

appearances. Or use it for so many different<br />

projects on their properties, whether corporate<br />

buildings, retail establishments or residential<br />

developments. Therefore, buyer<br />

awareness also factored heavily into what the<br />

program would need to accomplish.<br />

Another issue was the perceived difficulty<br />

in working with white or colored concrete.<br />

Focus groups studied contractors and specifiers<br />

to learn about their experiences. Some<br />

had very good results in special applications:<br />

colored driveways, yellow safety curbs and<br />

white barrier medians. Others noted a<br />

strong resistance to using products formulated<br />

with white cement due to uncertainty<br />

about results or ease of handling.<br />

PCA’s Program<br />

Given the challenges from producers and<br />

end users, it was obvious that promoting<br />

white and colored concrete had to be done<br />

from both directions to be effective. So, a<br />

two-pronged program was created to 1)<br />

increase awareness among specifiers and 2)<br />

support ready mixers to be able to meet a<br />

growing demand for decorative concrete.<br />

Idea brochures were distributed to architects,<br />

A white concrete pool surround keeps the deck<br />

surface cool under bare feet, even in hot sunshine.<br />

20 ı FALL <strong>2004</strong>

UP-FRONT THINKING THAT BREEDS BETTER DESIGN.<br />

We don't do software, but we can appreciate the "point-and-click"<br />

advantage of front discharge delivery. You will, too.<br />

Mixer truck operators will tell you that they'd much rather drive straight into<br />

a work site than back in. That's one of the chief advantages of an Indiana<br />

Phoenix mixer—total operator control—right in front of his eyes. And there<br />

are other advantages...faster loading and unloading; superior safety features;<br />

completely customized configurations; and an exclusive, customer-driven<br />

process that all lead to increased productivity and more profit per load. For the<br />

full story on the “Phoenix Process” and what up-front thinking can do for your<br />

operation, call us at 1-877-932-8203 or visit www.indianaphoenix.com.<br />

w w w . i n d i a n a p h o e n i x . c o m

feature<br />

Above: Coloring and stamping the concrete allows drives to be designed to complement the home’s<br />

architecture. Right: Stained concrete creates an elegant interior floor in this upscale living room.<br />

specifiers and owners so that they would<br />

start asking for decorative concrete products.<br />

Technical information was updated and<br />

expanded so that engineers, contractors and<br />

ready mixed producers would know how to<br />

work with concrete that contained white<br />

cement.<br />

The Art of <strong>Concrete</strong> is one of the backbones<br />

of PCA’s program. It’s a colorful<br />

brochure targeted to specifiers that talks<br />

about the beauty, versatility and value of<br />

white cement concrete. It presents cast-inplace,<br />

precast and tilt-up projects to show<br />

how white cement concrete can be used to<br />

create imaginative, attractive and energy efficient<br />

buildings and other structures.<br />

The Versatility of <strong>Concrete</strong> is also an idea<br />

brochure, geared heavily to homeowners and<br />

homebuyers to get them thinking about<br />

where they can use concrete products<br />

around their homes. Inside or outside, top<br />

to bottom, from countertops and floors to<br />

roof tiles, driveways, patios, pool decks and<br />

retaining walls, cement-based products offer<br />

durability and bring a high level of quality<br />

to any property.<br />

Several case studies highlight successful<br />

applications of white and colored concrete.<br />

White <strong>Concrete</strong> Brightens Highways of Hope<br />

talks about white concrete parapets on the<br />

Pennsylvania Turnpike. <strong>Ready</strong> Mix: Making<br />

the White Decision profiles a successful D.C.-<br />

area ready mixer and gives several examples<br />

of projects where white cement made a difference,<br />

including the Dulles Airport Expansion.<br />

Super Floors for Supermarkets examines<br />

how one ready mixed and contractor team<br />

has been building light reflective floors for<br />

grocery stores in the Pacific Northwest. And<br />

White <strong>Concrete</strong>: New Avenues of Safety takes a<br />

look at North Avenue in Chicago, where<br />

white curbs and medians mix with decorative<br />

tinted precast planter boxes to improve<br />

the safety and aesthetic aspects of a city<br />

street with heavy pedestrian traffic.<br />

Technical materials range from two-page<br />

tech briefs focused on a single topic (surface<br />

variety, light reflective floors, and mixing<br />

22 ı FALL <strong>2004</strong>

PREMIER DESIGN<br />

It’s the freedom to get the mixer you need and the freedom to have it built<br />

the way you want it. You’ve set your business apart through hard work,<br />

careful planning, wise decision-making and a keen sense of innovation.<br />

For us, that's familiar territory.<br />

Thirty years ago, we turned the industry on its ear with the first front-discharge<br />

mixer. And we’ve never looked back.<br />

With a wide range of configurations and options, your Premier Mixer is<br />

ready and waiting to be built to your individual specifications, to maximize<br />

the profit potential of your business.<br />

Call 800-678-5961 for a personal consultation with one of our representatives,<br />

and experience The Premier Mixer for yourself.<br />

7727 Freedom Way<br />

Fort Wayne, IN 46898-0070<br />

Office 800.678.5961<br />

Parts 800.433.6691<br />

Fax 260.497.0952<br />

© 2003 Terex-Advance

feature<br />

Putting It All Together<br />

All of the previously mentioned items<br />

were complied onto a compact disc, Exploring<br />

the Art of <strong>Concrete</strong>, to bring all the elements<br />

of the program together. The CD has<br />

the technical manual in three languages—<br />

English, Spanish, and French. There is a<br />

PowerPoint presentation based on The Art of<br />

<strong>Concrete</strong> that guides readers through the<br />

brochure benefit by benefit. There’s a collection<br />

of images from the publications for use<br />

in marketing or promotional activities. And<br />

it also contains a historical document library<br />

of architectural concrete literature from the<br />

PCA archives. If still more information is<br />

needed on a particular topic, links to other<br />

Light reflective floors used indoors improve<br />

lighting conditions, add safety, and are long<br />

lasting even with heavy foot traffic.<br />

and handling) to a 32-page manual called<br />

White Cement <strong>Concrete</strong> covering everything:<br />

applications, ingredients, designing, mixing<br />

and placing. A Guide for Specifying White<br />

and Colored <strong>Concrete</strong> is available from the<br />

PCA website for downloading at<br />

www.cement.org/decorative. Its conformance<br />

with the MasterSpec format makes it<br />

easy to incorporate directly into architects’<br />

specification documents.<br />

Using white<br />

concrete for bridge<br />

parapets adds high<br />

visual impact and<br />

increases safety,<br />

especially at night<br />

or in rainy<br />

conditions.<br />

24 ı FALL <strong>2004</strong>

concrete-related associations show just where<br />

to find help to make projects successful.<br />

All these efforts support the ready mixed<br />

industry by providing producers with the<br />

materials they need to be successful. It<br />

expands product lines. It creates more<br />

knowledgeable purchasers and specifiers.<br />

The net effect is increased business opportunities<br />

for ready mixed producers.<br />

And the opportunity is there for those<br />

who want it. Since 1999, gray portland<br />

cement usage has consistently run above 100<br />

million metric tons per year each year.<br />

Although white cement accounts for only<br />

about 1 percent of total annual cement tonnage,<br />

that adds up to a lot of white and colored<br />

concrete work for the ready mixed<br />

industry, precasters, and others.<br />

Good Results<br />

Getting the message out to all the right<br />

people is essential. Trade shows, mailings,<br />

website traffic and presentations are all<br />

important aspects of reaching the target<br />

audience. For the past few years, PCA has<br />

been spreading the word in all of these ways,<br />

using the literature described above.<br />

Early findings by the PCA Market<br />

Research department point to a start in the<br />

right direction. Using market research surveys,<br />

six questions on white or colored concrete<br />

were posed to homebuilders and<br />

buyers. Results show an increase in awareness<br />

and interest from 2001 to 2003. Not<br />

only were people more knowledgeable about<br />

various white and colored concrete products<br />

offered, they were also more likely to consider<br />

building with them or purchasing them in<br />

2003 than they had been in 2001.<br />

Decorative concrete is hitting its stride,<br />

so the timing is right for all of this information.<br />

People and corporations spend a lot of<br />

money to create safe, comfortable and<br />

durable buildings and properties. They<br />

look for attractive surfaces, interesting finishes<br />

and long-lasting results. <strong>Concrete</strong>,<br />

with its architectural and decorative capabilities,<br />

is often their product of choice. Or<br />

could be, if the awareness of its potential is<br />

promoted.<br />

Don’t Forget It’s Green<br />

There are sustainability aspects of decorative<br />

concrete, too. Ingredients are locally<br />

available and plentiful, like sand and gravel.<br />

<strong>Concrete</strong>’s durability makes the products<br />

cost effective over many years. When the<br />

time eventually comes, the products do wear<br />

out and may need to be replaced, but<br />

because concrete is recyclable, the environment<br />

is not unduly burdened.<br />

<strong>Concrete</strong> offers thermal mass for buildings,<br />

saving energy for heating and cooling.<br />

Light-colored floors save energy for interior<br />

lighting. Light-colored pavements reduce the<br />

urban heat island effect. <strong>Concrete</strong> itself is a<br />

low-embodied energy material. ■<br />

For more information about PCA’s white<br />

cement program, contact Jamie Farny, program<br />

manager at PCA, at 847/972-9172. To see<br />

(free) electronic versions of many of the documents<br />

described here, visit the Architectural<br />

and Decorative <strong>Concrete</strong> homepage of the PCA<br />

website at: www.cement.org/decorative.<br />

CONCRETE in focus ı 25

feature<br />

Establishing a<br />

Center for <strong>Concrete</strong> Research<br />

By Karthik Obla, Director of Research & Materials, NRMCA<br />

The <strong>National</strong> <strong>Ready</strong> <strong>Mixed</strong> <strong>Concrete</strong> <strong>Association</strong> established<br />

a research facility as early as 1928. This research<br />

laboratory has been dedicated to concrete and aggregate<br />

research and industry training and certification programs ever<br />

since. Pioneering work by the association, as directed by its committees,<br />

has helped establish many of the standards and specification<br />

requirements for ready mixed concrete. The primary focus of<br />

NRMCA’s research activities has always been on practical issues<br />

that benefit or impact the industry. These have included improvement<br />

of standards, material evaluation, troubleshooting and<br />

developing tools and methods to enhance the quality, predictability<br />

and uniformity of ready mixed concrete and aggregates for<br />

construction. The research and technical activities of NRMCA<br />

established its credibility and respect early with the strong leadership<br />

of people like Stanton Walker, Delmar Bloem, Richard<br />

A research cooperation agreement was signed on May 10, <strong>2004</strong> between<br />

The University of Maryland, Department of Civil and Environmental<br />

Engineering (UM-CE) and NRMCA towards establishing a Center for<br />

<strong>Concrete</strong> Research (CCR). The intent is to use the synergies of the academic<br />

community with the established NRMCA research laboratory to<br />

conduct applied research that benefits the industry. The agreement is<br />

expected to be mutually beneficial for both parties and there is potential<br />

for adding other organizations in the future. The agreement was signed<br />

by James Russ, NRMCA past chairman, on behalf of NRMCA and Dr.<br />

Ali Haghani, professor and chair of the Department of Civil and Environmental<br />

Engineering on behalf of UM-CE. Robert Garbini, Colin<br />

Lobo, Karthik Obla from NRMCA and Dimitrious Goulias from UM-<br />

CE were also present.<br />

26 ı FALL <strong>2004</strong>

Gaynor, Richard Meininger and Jon<br />

Mullarky. In 1998, the research and technical<br />

contributions of the NRMCA research<br />

program were recognized by the American<br />

<strong>Concrete</strong> Institute with the prestigious<br />

Arthur R. Anderson Award. Beyond technical<br />

issues and standards, the laboratory supports<br />

NRMCA initiatives in promotion,<br />

regulatory compliance and operations areas.<br />

The NRMCA research facility has been<br />

located in College Park, Maryland, about 2<br />

miles from the University of Maryland campus,<br />

since 1974. The research facility is supported<br />

by the members of the association<br />

and represents a benefit of membership in<br />

the NRMCA. This benefit is through the<br />

development of technical data that supports<br />

industry initiatives and the availability of the<br />

research facility for member product evaluations<br />

or consulting services at below market<br />

prices.<br />

The research facility consists of a 5000-<br />

square-foot building that maintains resources<br />

for standard and innovative testing of concrete<br />

and aggregate. The building has two<br />

strength testing machines and four environmentally<br />

controlled rooms for curing and<br />

testing materials under controlled temperature<br />

and moisture conditions. The NRMCA<br />

research laboratory participates in proficiency<br />

sample testing of the Cement and <strong>Concrete</strong><br />

Reference Laboratory (CCRL), is inspected<br />

biannually for conformance to the requirements<br />

of ASTM C 1077 and maintains its<br />

accreditation under the AASHTO Laboratory<br />

Accreditation Program.<br />

As industry pressures and initiatives have<br />

increased in the areas of concrete promotion,<br />

education and advocacy on the legislative<br />

and regulatory fronts, NRMCA has<br />

responded by elevating professional expertise<br />

in those areas. This has caused a reevaluation<br />

and some degree of constraint on the<br />

research initiatives. Simply put, the research<br />

facility has to generate revenue in addition<br />

to member support to elevate its resources<br />

and capabilities. The industry’s commitment<br />

to research and education, however, is clearly<br />

demonstrated in the pledges of approximately<br />

$14 million to the RMC Research Foundation<br />

and the projects currently being<br />

funded by that organization.<br />

NRMCA is currently working on establishing<br />

a Center for <strong>Concrete</strong> Research<br />

(CCR). As currently proposed, the CCR will<br />

be a consortium between NRMCA, the University<br />

of Maryland (UM) and the Middle<br />

Tennessee State University (MTSU). Interest<br />

of the participation of other universities in<br />

the CCR is being solicited. A concrete<br />

research consortium that partners industry<br />

initiatives with academia is seen to be of<br />

mutual benefit. The CCR will have a clear<br />

understanding of technical issues facing the<br />

industry through the direction of the<br />

NRMCA’s Research, Engineering and Stan-<br />

As the ready mixed concrete industry has progressed<br />

to a higher level of technical competence and product<br />

development, the argument has been made that<br />

individual companies can work on these initiatives<br />

themselves.<br />

dards (RES) Committee and the participation<br />

of its engineering division staff in standards-setting<br />

organizations. Academic<br />

institutions bring with them their research<br />

expertise and ability to solicit research grants<br />

from other organizations that funds the education<br />

of graduate and undergraduate students.<br />

This synergy ensures that the<br />

participating academic institutions are connected<br />

to industry needs and develop<br />

research initiatives that will have an<br />

immediate impact and benefit to the<br />

industry. Students working on these<br />

research programs are also more<br />

tuned in to the concrete industry,<br />

will likely join its workforce and<br />

thereby elevate its technical competence<br />

and credibility.<br />

The primary goal of the CCR is to<br />

become nationally recognized for its expertise<br />

in applied concrete research. Applied concrete<br />

research here is defined as that research that<br />

will have an impact on the ready mixed concrete<br />

industry in the short term of less than<br />

four years. Examples of current topics of<br />

interest are: self consolidating concrete; concrete<br />

maturity; optimizing mix designs for<br />

performance; effects of aggregate grading and<br />

other characteristics; evaluation of new methods<br />

for acceptance such as the air void analyzer<br />

or microwave oven test; predicting<br />

setting characteristics of concrete; alkali silica<br />

reactivity tests; pervious concrete; effects of<br />

aggregate fines; concrete mixtures for sustainability;<br />

sorptivity and other tests to evaluate<br />

durability/cracking; and reuse of returned or<br />

recycled concrete and wash water. The ready<br />

mixed concrete industry needs to have a<br />

framework and a resource, represented by the<br />

proposed CCR, to address these technical<br />

issues that continually arise. Technical data<br />

CONCRETE in focus ı 27

feature<br />

provides a stronger basis to support industry<br />

positions than opinions or conjecture. Credible<br />

and unbiased technical data ensures a<br />

proper dialogue in lieu of being dictated to.<br />

The CCR will focus on those topics that are<br />

most likely to influence the ready mixed<br />

concrete industry in a significant way within<br />

the next four years. It will help build industry<br />

positions on these technical issues as well<br />

as foster a positive technical change in the<br />

ready mixed concrete industry. In addition,<br />

CCR will also research topics that save cost,<br />

increase market share, or provide educational<br />

value for the ready mixed concrete producer.<br />

NRMCA member companies will substantially<br />

gain from CCR’s work. Some<br />

potential member benefits are:<br />

a. High quality research reports on stateof-the-art<br />

subjects that will impact a<br />

member company’s business practice.<br />

b. Help formulate industry positions on<br />

When You’re Really Serious<br />

About Saving Weight<br />

on Lift Axles…<br />

The New 8K Steerable Tru-Track Super Lite<br />

From Watson & Chalin is 374 Pounds Lighter<br />

Than Our Standard Lightweight Lift Axle<br />

SL-0851TT<br />

Installed Weight of 895 Pounds<br />

Including Wheels and Tires<br />

800.445.0736 • www.WatsonSuspensions.com<br />

important issues that progress the ability<br />

of the industry to be more in control<br />

of the product they produce.<br />

c. Members can use the CCR reports for<br />

marketing purposes.<br />

d. Research results can potentially reduce<br />

cost to the industry and increase concrete<br />

market share.<br />

e. Develop educational information of<br />

value to the industry and its customers.<br />

As the ready mixed concrete industry has<br />

progressed to a higher level of technical<br />

competence and product development, the<br />

argument has been made that individual<br />

companies can work on these initiatives<br />

themselves. The reality is that the laboratory<br />

facilities of most companies have their<br />

hands full with daily QA-QC activities,<br />

trouble shooting and product development<br />

for their specific needs and do not have<br />

time or resources to devote to initiatives or<br />

research that will have an overall impact on<br />

the concrete industry. When they do spend<br />

time on these initiatives they would only<br />

benefit from the CCR’s work that will surely<br />

shorten their learning curve. One example<br />

is the NRMCA’s research on the reuse of<br />

wash water that has to translate to a company’s<br />

specific materials and production<br />

processes.<br />

In addition, CCR will offer other member<br />

benefits that are equally important. They are:<br />

a. High quality consulting testing at<br />

below market costs for members, thus<br />

helping them reduce costs. Many<br />

members cannot perform these tests.<br />

b. Educate industry personnel and testing<br />

technicians for industry certification<br />

programs and promote the<br />

development of performance-based<br />

concrete mixtures.<br />

CCR’s programs will be jointly managed<br />

by NRMCA’s engineering staff and UMD<br />

with substantial input from NRMCA’s RES<br />

committee. Apart from significant investments<br />

from NRMCA, CCR will depend<br />

upon funding from sources such as the<br />

RMC Research Foundation and external<br />

agencies such as state and federal highway<br />

agencies and other opportunities available<br />

to the university partners. If you are interested<br />

in the planned activities of CCR,<br />

please contact NRMCA’s Colin Lobo at<br />

clobo@nrmca.org or Karthik Obla at<br />

kobla@nrmca.org.<br />

■<br />

28 ı FALL <strong>2004</strong>

environmental scene<br />

To LEED or Not to LEED<br />

By Scott Hammersley, New Rock Materials<br />

The American business community is<br />

constantly coming up with buzz<br />

words & phrases that find their way<br />

into our everyday lingo. Remember “networking”<br />

& “out of the box thinking” or how<br />

about “dot-com” One of the newer terms is<br />

“Sustainability;” perhaps this one will stick<br />

around for no other reason than the definition<br />

of the word. Another buzz word for the<br />

construction industry is LEED, referring<br />

to the Leadership in Energy and Environmental<br />

Design standard developed by the U.S.<br />

Green Building Council (USGBC).<br />

LEED was created to:<br />

• Define “green building” by establishing<br />

a common standard of measurement<br />

• Promote integrated, whole-building<br />

design practices<br />

• Recognize environmental leadership in<br />

the building industry<br />

• Stimulate green competition<br />

• Raise consumer awareness of green<br />

building benefits<br />

• Transform the building market<br />

All right, so what does this mean to us as<br />

ready mixed producers Well, if we indeed<br />

manufacture “the most versatile building<br />

product in the world,” and we are truly committed<br />

to “sustainability,” then we better get<br />

on this train in a big way!<br />

Some of the largest concrete consumers in<br />

the nation are members of the USGBC.<br />

Companies like Centex Construction, Clark<br />

Construction Group, DPR Construction,<br />

Gilbane Building Company and Kiewit Construction<br />

Company are just a few of hundreds<br />

of our customers who have joined the council<br />

to help bring value back to their customers.<br />

In a nutshell, the LEED system works on<br />

a point system, assigning credits through the<br />

use of specific rating criteria. The more environmentally<br />

and energy efficient, the higher<br />

the point rating achieved. Additional points<br />

can be added for using recycled materials. Use<br />

of reclaimed aggregates, as well as costs saved<br />

from not transporting that material, can gain<br />

you credits. The scheme attempts to take a<br />

comprehensive look at the whole environmental<br />

big picture. The LEED system does<br />

not have a provision that allows credit for<br />

using recycle water in the mix. This example<br />

highlights one area where NRMCA hopes to<br />

influence the USGBC standard.<br />

Let me give you an example of how<br />

LEED has helped my companies in the recent<br />

past, and can do the same thing for the entire<br />

industry. In one of our markets, a LEED-certified<br />

project was in the pre-bid stage. Part of<br />

the pre-qualification process entails meeting<br />

safety and bond requirements along with the<br />

development of a resume demonstrating the<br />

ability to deliver quality concrete in an environmentally<br />

sound manner. Also required is<br />

the mandatory completion of a LEED worksheet<br />

depicting the material supplier’s dedication<br />

to environmental compliance as well as a<br />

description of their recycling capabilities.<br />

Because of our company’s history, along with<br />

awards and efforts to increase recycling and<br />

exceed environmental standards, we were<br />

awarded the project at higher unit pricing<br />

than our competition!<br />

This account is a prime example of what<br />

we as an industry have been trying to do since<br />

the first days of RMC 2000. Our goal was to<br />

convince the general public (and unfortunately<br />

some in our own ranks) that we are not<br />

selling a commodity, but indeed one of the<br />

most environmentally friendly and versatile<br />

building materials in the world. As I try to<br />

convey to our students in the NRMCA Environmental<br />

Course, a “proactive” as opposed<br />

to a “reactive” approach to environmental<br />

compliance can be a profit center instead of a<br />

liability. The above example is living proof!<br />

NRMCA is currently working with the<br />

USGBC to examine their credit scheme and<br />

to encourage a system that takes into account<br />

the benefits of building with ready mixed<br />

concrete. NRMCA endeavors to increase our<br />

share of points on a given LEED project to<br />

further set us apart from competing building<br />

materials such as asphalt and steel. Other<br />

efforts underway focus on the nationwide<br />

promotion of our environmentally friendly<br />

products like pervious pavements, tilt up<br />

walls and insulated concrete forms. ■<br />

For more detailed information on the<br />

Green Building Council and the LEED<br />

program, go to their website at www.usgbc.org<br />

or make plans to attend the next NRMCA<br />

Environmental Course in November, <strong>2004</strong>.<br />

CONCRETE in focus ı 29

tech talk<br />

Understanding<br />

the LEED Credit<br />

for Recycled Content<br />

By Lionel Lemay, PE, SE,<br />

Senior Director of Applied Engineering, NRMCA<br />

If you haven’t already supplied concrete for a LEED project, there is a<br />

good chance you will soon. LEED, which stands for Leadership in Energy<br />

and Environmental Design, is a rating system that is quickly becoming<br />

the standard for green building design and construction. It was<br />

developed through a consensus process by the United States Green Building<br />

Council (USGBC), a non-profit organization dedicated to promoting<br />

buildings that are environmentally responsible, profitable and healthy<br />

places to live and work.<br />

The LEED rating system is credit-based, allowing projects to earn<br />

points for environmentally friendly actions taken during the design and<br />

construction process. A project requires a minimum of 26 points to be<br />

LEED certified. There are advanced levels of certification, including silver,<br />

gold, and platinum, requiring a minimum of 33, 39 and 52 points, respectively.<br />

There are five core credit categories to obtain LEED points: Sustainable<br />

Sites worth up to 14 points, Water Efficiency worth up to 5 points,<br />

Energy and Atmosphere worth up to 17 points, Materials and Resources<br />

worth up to 13 points, and Indoor Environmental Quality worth up to 15<br />

points. There is a sixth category called Innovation and Design Process for<br />

an additional 5 points. There are a total of 69 LEED points available.<br />

The LEED point system is not defined in terms of materials or specific<br />

systems but describes credits in general terms. <strong>Concrete</strong> can play a significant<br />

role in obtaining LEED points in every credit category. For example,<br />

Photo credit: Jim Schafer Location<br />

Photography<br />

30 ı FALL <strong>2004</strong>

The Clearview Elementary School in Hanover, Penn., incorporates concrete to achieve<br />

LEED Gold certification. The project was built using insulating concrete forms to<br />

obtain LEED points for energy efficiency and used high volumes of slag in the concrete<br />

to obtain LEED points for recycled content. <strong>Concrete</strong> also helped achieve LEED points<br />

for using regionally manufactured and harvested materials. At left: NRMCA is a<br />

registered provider with the American Institute of Architects Continuing Education<br />

Systems (AIA/CES) and offers several seminars on concrete technology including LEED<br />

Green Building Rating System and <strong>Concrete</strong>.<br />

CONCRETE in focus ı 31

tech talk<br />

one LEED point is earned for using a light<br />

colored pavement, such as concrete, for 30%<br />

of a site’s paved surfaces. Using pervious<br />

concrete pavement to reduce stormwater<br />

runoff can earn one LEED point. Using<br />

energy efficient wall systems, such as tilt-up<br />

concrete walls or insulating concrete forms,<br />

can contribute to gaining LEED points.<br />

<strong>Concrete</strong> contributes to available LEED<br />

points by using regionally manufactured<br />

materials—concrete is made within a 500-<br />

mile radius of a building site and most of the<br />

materials are also harvested within 500 miles<br />

of the site.<br />

<strong>Concrete</strong> also contributes to LEED<br />

points available for using recycled products.<br />

The requirement is to use materials with<br />

recycled content such that the sum of the<br />

post-consumer recycled content plus onehalf<br />

of the post-industrial recycled content<br />

totals 5% for 1 point or 10% for 2 points.<br />

The calculation is based on value or cost of<br />

materials. The value of the recycled content<br />

portion of a material is determined by<br />

dividing the weight of recycled content in<br />

the item by the total weight of all materials<br />

in the item, then multiplying the resulting<br />

percentage by the total value of the item.<br />

Supplementary cementitious materials<br />

(SCMs) such as fly ash, slag and silica fume<br />

are considered post-industrial recycled content.<br />

Example: Assume a project is built using<br />

tilt-up concrete walls, slab-on-grade, concrete<br />

footings and a concrete parking area.<br />

The total project cost is $5 million and the<br />

total cost of materials is $2.25 million. The<br />

total amount of concrete used on the project<br />

is 1,850 cubic yards at a cost of $70 per<br />

cubic yard. The mix design calls for 225<br />

pounds of fly ash per cubic yard. The recycled<br />

content rate is calculated as follows: (at<br />

right)<br />

To obtain one LEED point for this project,<br />

recycled content rates for all other items<br />

must total 4.84% or more to achieve the 5%<br />

minimum requirement. Other strategies for<br />

increasing recycled content in concrete<br />

include using flowable fill that contains high<br />

volumes of fly ash, using recycled aggregate<br />

*post-industrial recycled content is given 1/2<br />

credit.<br />

Fly Ash for <strong>Concrete</strong> Products<br />

Delivering performance<br />

when performance counts.<br />

Every time.<br />

Quality. Reliability. Service.<br />

ISG Resources is the nation’s leading<br />

supplier of fly ash to the concrete<br />

industry. Operating coast to coast,<br />

ISG provides more than material – we<br />

provide unparalleled customer service<br />

and technical support to ensure you<br />

get results.<br />

From ready mixed to precast.<br />

Highways, structures, flowable fills.<br />

Your product will perform better with<br />

fly ash.<br />

Performance Building Materials from<br />

Coal Combustion Products<br />

For information, call John Ward at 888-236-6236<br />

www.flyash.com<br />

32 ı FALL <strong>2004</strong>

tech talk<br />

The seminar was developed to provide continuing<br />

education for architects and engineers but also serves<br />

as an excellent introduction to LEED for ready mixed<br />

concrete producers.<br />

in concrete, or using other SCMs such as<br />

slag in concrete.<br />

There is also an opportunity to obtain<br />

another LEED point by using SCMs in concrete.<br />

The USGBC has issued a Credit Interpretation<br />

that states that one Innovation<br />

Point will be awarded for reducing the total<br />

portland cement content in concrete. The<br />

requirement is to reduce the total carbon<br />

dioxide (CO 2 ) for all concrete on a project<br />

by a minimum of 40% from standard baseline<br />

mixes. <strong>Concrete</strong> must make up a significant<br />

portion of the work. The assumption is<br />

that 1 pound of portland cement is equivalent<br />

to 1 pound of CO 2 . Baseline mixes are<br />

defined as standard 28-day compressive<br />

strength mix designs for the region. SCMs<br />

allowed include fly ash, slag, silica fume and<br />

rice hull ash.<br />

Example. Assume the structural requirement<br />

for concrete is 4,000 psi. The standard<br />

mix design for the area uses 564 lbs. of portland<br />

cement per cubic yard. To obtain one<br />

LEED point, one would need to reduce the<br />

portland cement content by 40% or by 227<br />

lbs. One strategy would be to require compressive<br />

strength to reach 4,000 psi at 90<br />

days instead of 28 days, which could result<br />

in a reduction of portland cement by 100<br />

lbs. An additional 127 lbs of portland<br />

cement could be replaced with fly ash to<br />

achieve the required 40% CO 2 reduction.<br />

Keep in mind that if the standard baseline<br />

mix for the region already contained fly<br />

ash or other SCMs, then obtaining the<br />

LEED Innovation Point for reducing CO 2<br />

in concrete would be even more difficult.<br />

If ready mixed concrete producers are<br />

going to play a key role in green building<br />

they must have a thorough understanding of<br />

the LEED process. By working with architects,<br />

engineers and contractors to maximize<br />

LEED points, producers will help concrete<br />

develop a competitive advantage over other<br />

materials.<br />

For starters, concrete producers should<br />

consider taking NRMCA’s seminar titled<br />

LEED Green Building Rating System and<br />

<strong>Concrete</strong>. The seminar was developed to<br />

provide continuing education for architects<br />

and engineers but also serves as an excellent<br />

introduction to LEED for ready mixed concrete<br />

producers. To arrange for a seminar,<br />

contact Lionel Lemay, senior director<br />

of applied engineering at NRMCA,<br />

LLemay@nrmca.org, (847) 918-7101. Visit<br />

www.nrmca.org for additional information<br />

on continuing education available from<br />

NRMCA.<br />

■<br />

Perfecting the Art of <strong>Concrete</strong> Production<br />

Telephone: 514 634 7083 • Fax: 514 639 6945<br />

E-mail: scaletron@scaletron.com<br />

For the latest information, visit our Web site:<br />

www.scaletron.com<br />

or call us at 1-800-632-7083<br />

<strong>Ready</strong>-Mix enterprise<br />

software wins back the<br />

profit you’ve been giving<br />

to the competition.<br />

• BATCHLINK for single<br />

plant operations<br />

• BEAVER for multiple<br />

plant operations,<br />

including quarries<br />

• Fine-tunes your mix<br />

design to give better<br />

quality product.<br />

• Gives accurate pricing<br />

based on true material<br />

costs.<br />

• Charges for all the<br />

little extras you missed<br />

out on before.<br />

• Gives you total control<br />

of your business.<br />

• Integrated quarry &<br />

readymix operations.<br />

• Mix design management.<br />

• Order entry.<br />

• Truck fleet management.<br />

• Order scheduling.<br />

• Delivery scheduling.<br />

• Batching controls.<br />

• Microwave moisture<br />

sensing.<br />

• Dispatching/ticketing.<br />

• Invoicing, link to<br />

accounting.<br />

• Aggregate gradation<br />

analysis.<br />

• Mix design formulation.<br />

• Inventory control.<br />

• Customizable delivery<br />

tickets and reports.<br />

• Twin shaft mixers.<br />

440 - 19th Ave. Suite 230, Lachine, QC, Canada, H8S 3S2<br />

102 A West Service Road, Suite 128, Champlain, New-York USA 12919<br />

34 ı FALL <strong>2004</strong>

feature<br />

OSHA<br />

Record Keeping<br />

Requirements for<br />

Injuries and Illnesses<br />

By Rick Maidens, Director of Safety and Risk Management, US <strong>Concrete</strong>, Inc. and<br />

Thomas Harman, Director of Safety Compliance, NRMCA<br />

In January 2002, the Occupational Safety and Health Administration<br />

(OSHA) changed its requirements for recording occupational injuries<br />

and illnesses. Forms, new cases and general reporting criteria as well as<br />

other categorical items were redefined. With only a few exceptions, the<br />

new standard streamlined the process and made the procedure easier to<br />

understand. None of the changes affected how incidence rates are calculated.<br />

However, one change in particular affected the severity rate, which<br />

is considered the indicator of how serious an injury/illness is. The severity<br />

rate is an arbitrary measure and is based on the days away from work<br />

from all injuries. After two years, the changes have been viewed as positive<br />

by most workplace safety and health practitioners.<br />

Forms<br />

The designation for the forms changed and a form was added. The<br />

current OSHA 300 log corresponds with the previously required<br />

OSHA 200 log, and the OSHA 300A summary is a new form that<br />

combines the injury/illness information located on the 300 log. The<br />

injury report is called the OSHA 301, and this has replaced the 101<br />

supplemental report of injury. This form details items about an injury<br />

such as cause and preventive measures.<br />

The greatest change is in the OSHA 300A summary log. The format<br />

is such that the user is allowed to easily tally the information in a<br />

way that facilitates incidence rates computation. The only additional<br />

piece of information that is needed and now is required by the standard<br />

to be kept by the employer is the number of employee hours.<br />

The posting requirement for the 300A summary log is now ninety<br />

days, compared with either 28 or 29 days, depending on whether it is a<br />

leap year. Posting now must be done from February 1 through April 30<br />

of each year.<br />

New Cases<br />

What constitutes a new case in the new standard A new case occurs<br />

when an employee has not previously experienced an injury or illness<br />